Mothproof and mildewproof wood-plastic wallboard and production method thereof

The technology of a wood-plastic wallboard and a production method is applied to the anti-mildew wood-plastic wallboard and its production, and the field of moth prevention, which can solve the problem of unsightly, easy to break, fall off, composite wallboard and solid wood wallboard, which are easy to be moth and mildew. and other problems, to achieve the effect of clear ratio, reasonable method, and easy to understand preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

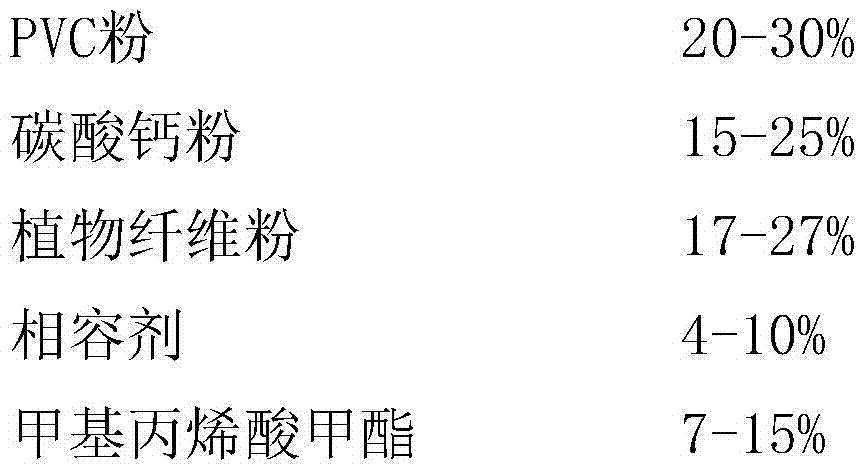

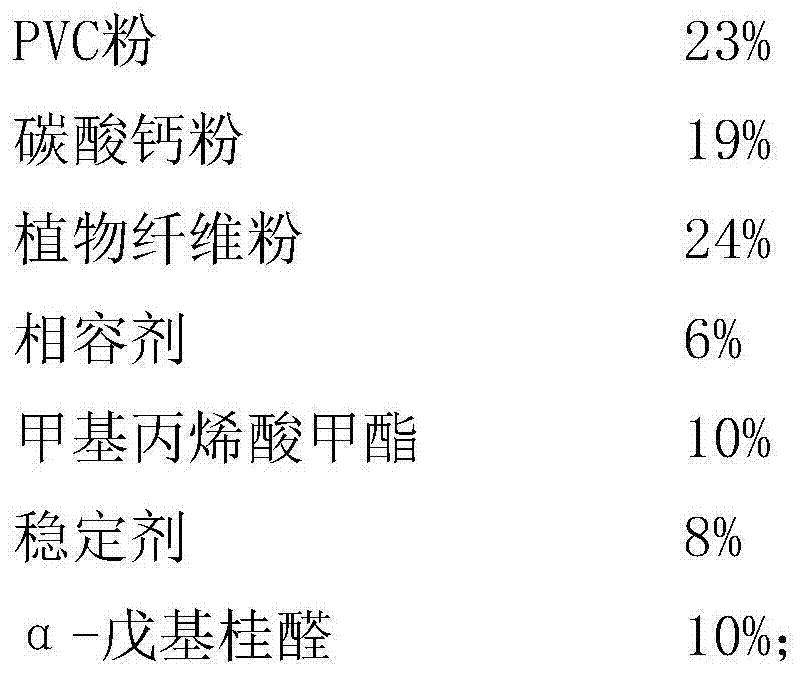

[0021] A moth-proof and mildew-proof wood-plastic wallboard, characterized in that it consists of the following components,

[0022]

[0023] A method for making a moth-proof and mildew-proof wood-plastic wallboard, characterized in that it comprises the following steps,

[0024] Step 1. Put the materials into the mixer in the order of PVC powder, methyl methacrylate, stabilizer, plant fiber powder, α-amyl cinnamaldehyde, calcium carbonate powder, and compatibilizer, and add them every 8 minutes. For one material, the mixer does not stop working during the whole process of stirring, and continues stirring for 20 minutes after all the materials are added;

[0025] Step 2, put the above-mentioned stirred materials into a sealed metal container with a temperature of 8-11°C and let...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com