Moisture and mildew resistant wood plastic floor and production method thereof

A wood-plastic floor and anti-mildew technology, which is applied in the direction of construction, building structure, floor, etc., can solve the problems of users such as trouble, not moisture-proof, cracking, etc., and achieves easy-to-understand preparation methods, good moisture-proof performance, and reasonable methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

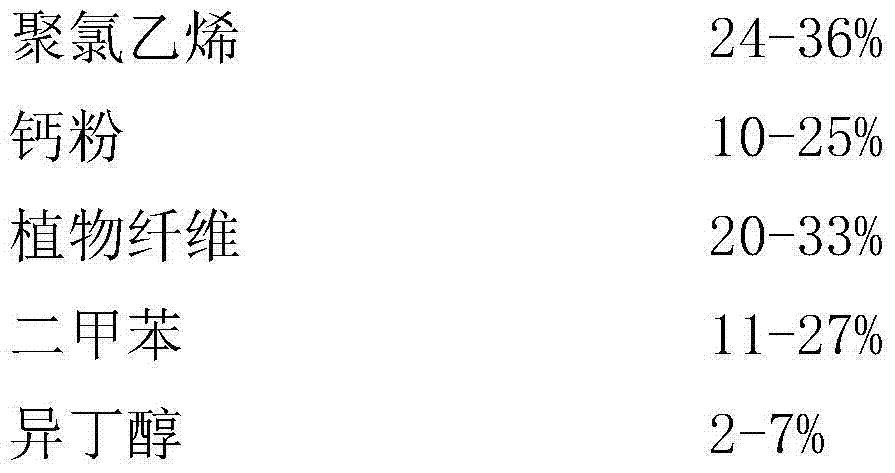

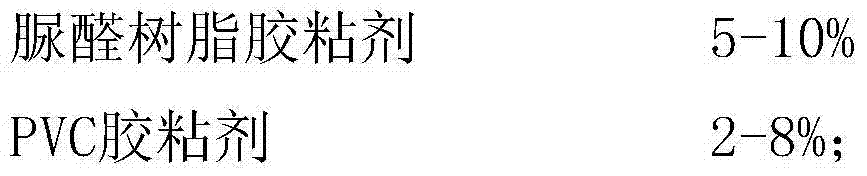

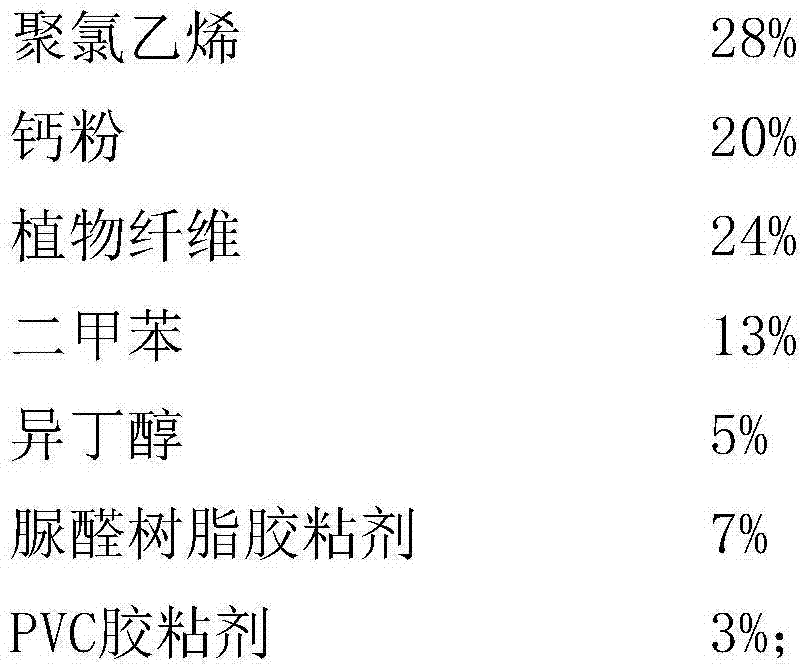

[0021] A moisture-proof, mildew-proof wood-plastic floor, the best ingredients of the product are,

[0022]

[0023] A method for preparing a moisture-proof and mildew-proof wood-plastic floor, characterized in that it comprises the following steps,

[0024] Step 1. Put the polyvinyl chloride and plant fiber into a pulverizer and pulverize them into powder, and then store them in sealed storage boxes;

[0025] Step 2. Put the crushed plant fibers in a blender and stir, then add calcium powder, isobutanol, and polyvinyl chloride in sequence, and add a material every 4 minutes, adding while stirring, when all the materials are added Stir for 7 minutes, add PVC adhesive, continue to stir for 10 minutes, then add xylene, add urea-formaldehyde resin adhesive after stirring for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com