Flame-proof formaldehyde-free wood-plastic wall plate and preparation method thereof

A wood-plastic wallboard and formaldehyde technology, which is applied in construction, building structure, floor, etc., can solve the problems of human hazards, wood-plastic wallboards without fire protection, and high toxicity of wallboards, and achieve clear proportions and reasonable methods , The effect of the preparation method is easy to understand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

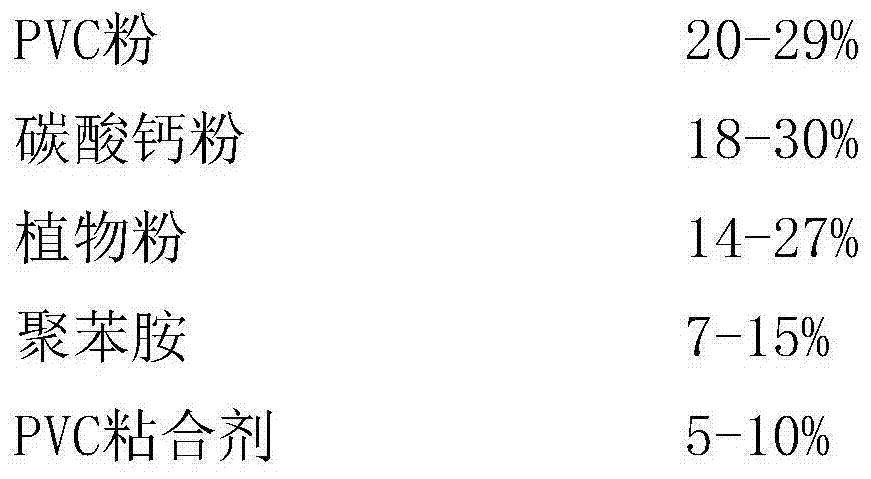

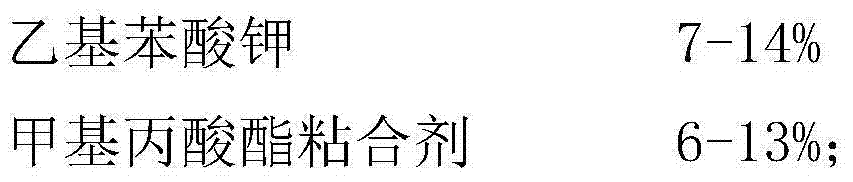

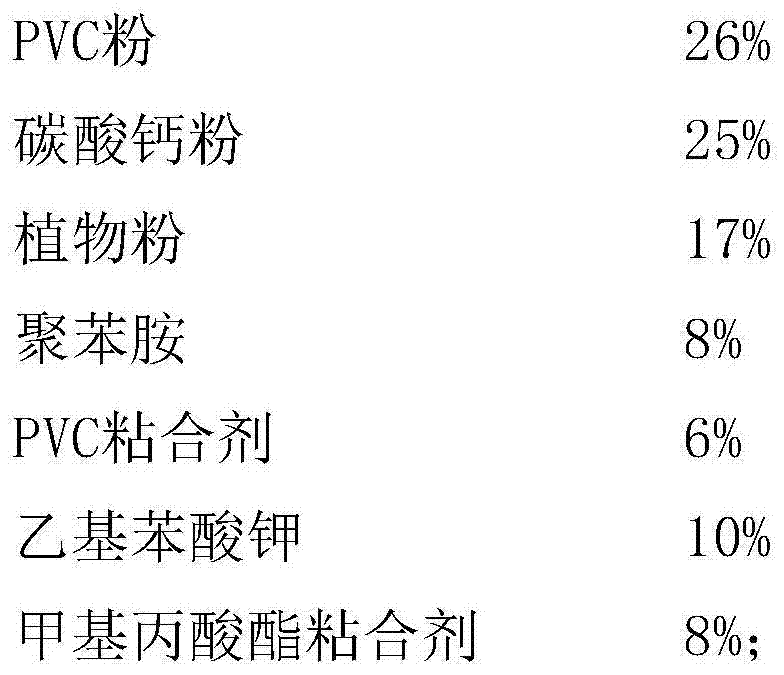

[0021] A fireproof, formaldehyde-free wood-plastic wallboard, characterized in that: the best composition of the product is,

[0022]

[0023] A method for preparing a fireproof, formaldehyde-free wood-plastic wallboard, characterized in that it comprises the following steps,

[0024] Step 1. Add the above-mentioned materials into the mixer in the order of plant powder, potassium ethylbenzoate, polyaniline, methyl propionate adhesive, calcium carbonate powder, PVC powder, and PVC adhesive, and stir each time Add one material every 6 minutes, the mixer will not stop working during the whole process of stirring, and continue stirring for 15 minutes after all the materials are added;

[0025] Step 2, put the above-mentioned stirred materials into a sealed storage tank with a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com