Automatic cleaning oil tank

An automatic cleaning and oil tank technology, which is applied in the direction of engine components, lubricating oil containers, engine lubrication, etc., can solve the problems of shortening the service life of lubricating oil, increasing maintenance costs, and deteriorating equipment operation status, so as to avoid accidents, The effect of reducing maintenance costs and avoiding overpressure at the outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

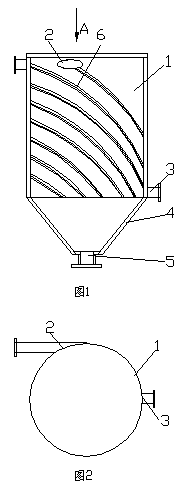

[0018] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along direction A, as shown in the figure: the self-cleaning circulating oil tank of this embodiment includes a cylindrical box 1, and the cylindrical box 1 is provided with an oil inlet 1 near the upper end and an oil outlet near the lower end. Port 3, the oil inlet direction of the oil inlet is along the tangential direction of the inner wall of the cylindrical box, and the lower end surface of the cylindrical box 1 is an inverted tapered structure 4.

[0019] The inner wall of the cylindrical box is provided with a spiral blade plate 6, and the expansion direction of the spiral blade plate 6 from top to bottom is consistent with the only direction; the structure of the spiral blade 6 is added to further guide the lubricating oil to swirl, so that the impurities are quickly Deposits to increase the separation effect.

[0020] The bottom of the lower end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com