Highly energy saving non-smoke corresponding burning type normal pressure hot water boiler

A hot water boiler, smoke and dust technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of shortening the service life of the boiler, low thermal efficiency, water pipe burst, etc., and achieve long service life and heat exchange efficiency. High, full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

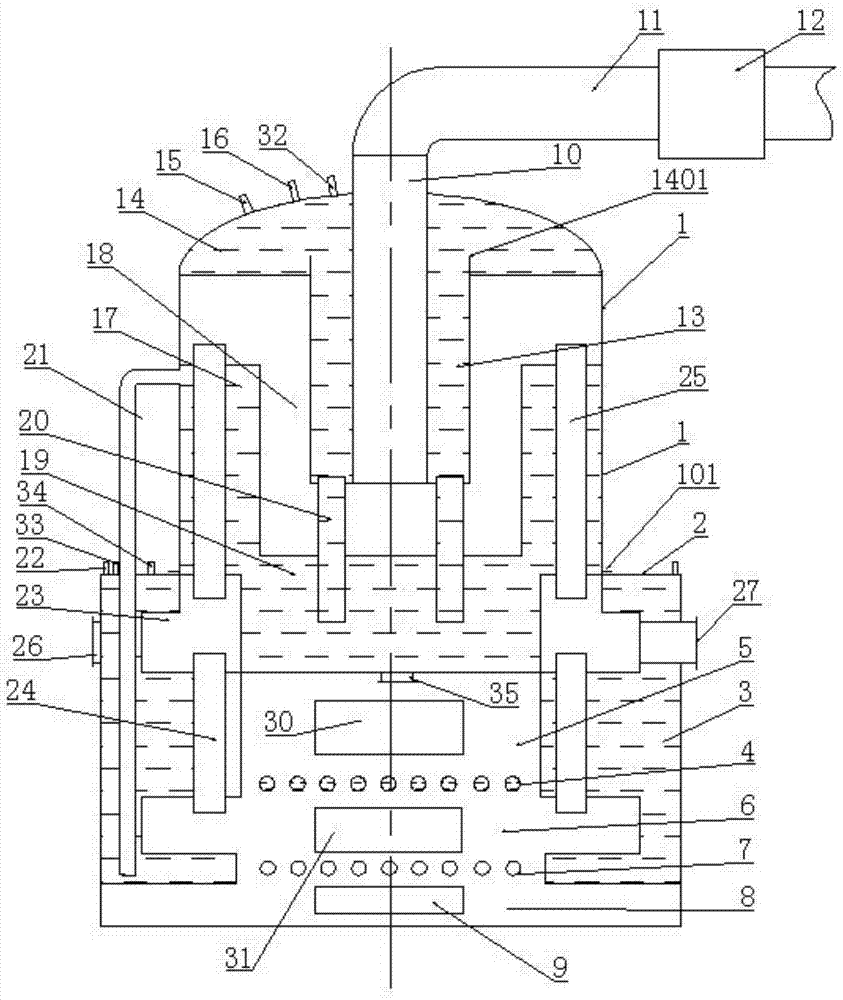

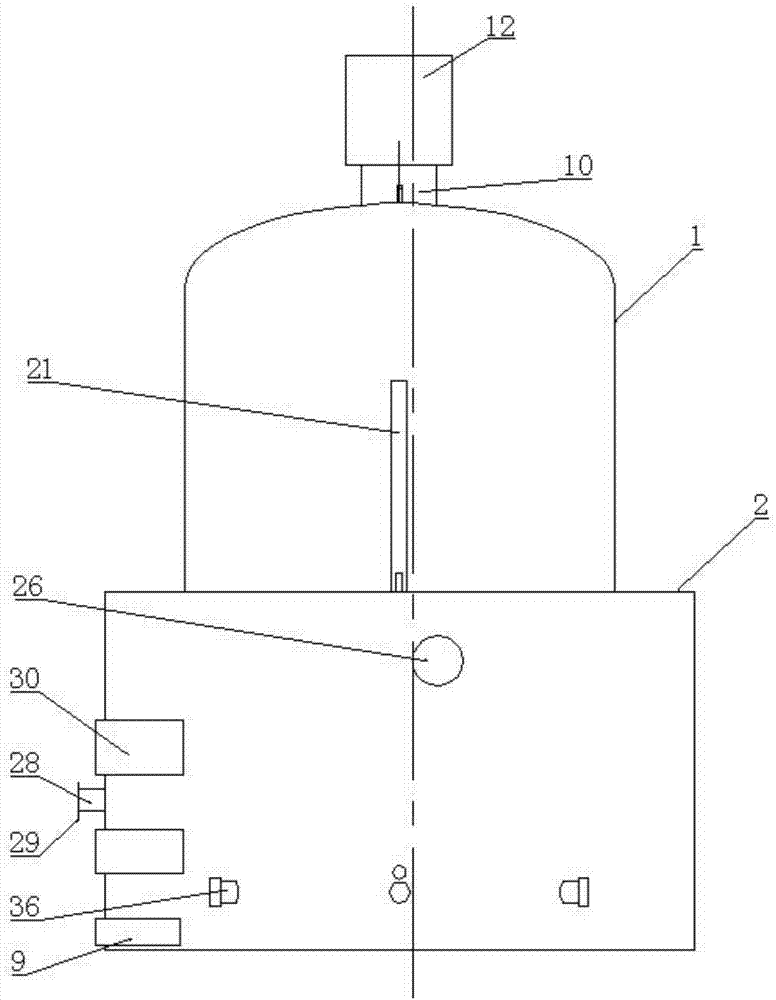

[0026] like figure 1 and figure 2 As shown, the high-energy-saving smoke-free two-firing atmospheric hot water boiler includes upper and lower furnace bodies 1 and 2, the lower furnace body 2 is provided with a water jacket 3 in the lower furnace body, and the lower furnace body 2 is provided with a lower furnace body and a lower furnace body. The water pipe grate 4 connected to the water jacket 3 is enclosed in the furnace body, and the combustion chamber in the lower furnace body is divided into the main combustion chamber 5 and the auxiliary combustion chamber 6 from top to bottom through the water pipe fire grate 4. The bottom of the auxiliary combustion chamber 6 is provided with a grate 7 , the lower furnace body 2 is located below the grate 7 as the ash chamber 8, and the ash door 9 is arranged on the lower furnace body 2 corresponding to the ash chamber 8; A chimney 11 is arranged on the chimney 11, an induced draft fan 12 is arranged on the chimney 11, a chimney out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com