Manufacturing method of atmospheric corrosion monitoring sensor

A technology for monitoring sensors and manufacturing methods, applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve problems such as manufacturing difficulties, achieve improved reliability and durability, strong operability, and materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

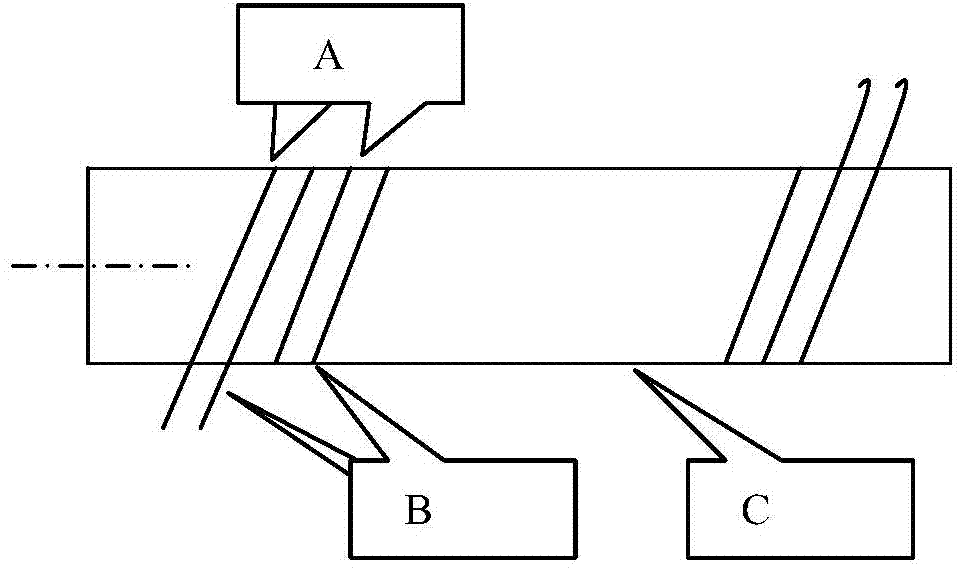

Image

Examples

Embodiment 1

[0015] Use iron wire and copper wire with a diameter of 1mm, and the copper wire is an insulated enameled wire. Coat a thin layer of epoxy resin on a plexiglass cylinder with a diameter of 50 mm. Before the resin is cured, wind the iron wire and copper wire side by side around the cylinder for 50 turns, and then coat the surface of the metal wire with epoxy resin. After the epoxy resin is cured , the upper grinding machine grinds the outer diameter of the wound cylinder to 51mm. At this time, the two metal wires are exposed, and the insulation is good at the same time. The iron wire and the copper wire are respectively drawn out to form a Kovarni battery corrosion sensor.

[0016] After the sensor is completed, immerse it in 1% NaCl aqueous solution to measure its initial current value I 0 . Then expose (use) the sensor under natural conditions for a certain period of time, then polish the surface, and measure its current value I by immersing in 1% NaCl aqueous solution i , ...

Embodiment 2

[0020] Choose aluminum wire and copper wire with a diameter of 2mm, of which the copper wire is an insulating enameled wire, and coat a thin layer of epoxy resin on an engineering plastic cylinder with a diameter of 60mm. Before the resin is cured, wind the aluminum wire and copper wire side by side on the cylinder. 40 circles on the body, and then coat the surface of the wire with epoxy resin. After the epoxy resin is cured, the upper grinder grinds the diameter of the outer surface of the wound cylinder to 62mm. At this time, the two kinds of metal wires are exposed, and the insulation is good at the same time. The aluminum wire and the copper wire are respectively led out with wires to form a kohl Nickel battery corrosion sensor.

[0021] After the sensor is ready, immerse it in 1% NaCl aqueous solution to measure its initial current value I 0 . Then expose (use) the sensor under natural conditions for a certain period of time, then polish the surface, and measure its cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com