A multifunctional processing system for circuit breaker contacts

A processing system and multi-functional technology, applied in the direction of circuits, electrical components, electrical switches, etc., can solve the problems of unstable continuous and efficient welding, low degree of automation, low work efficiency, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

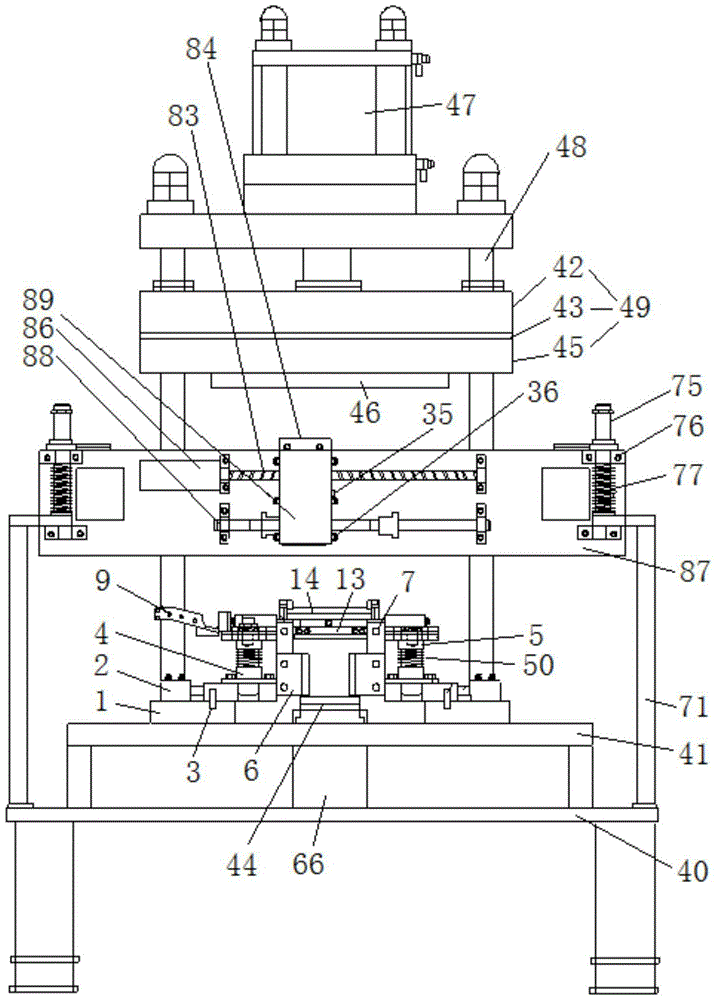

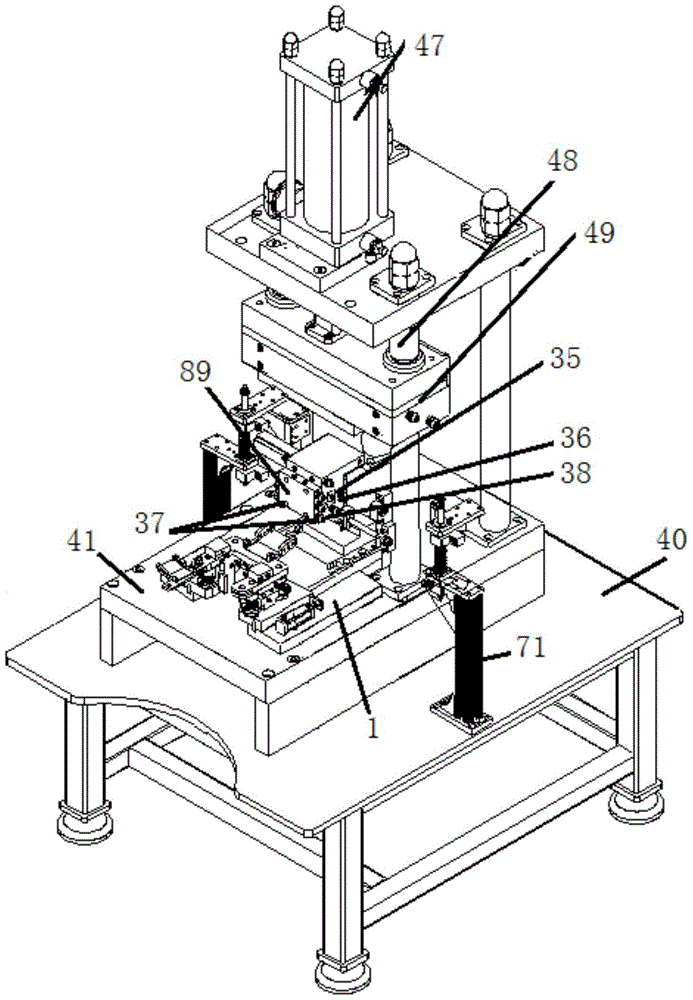

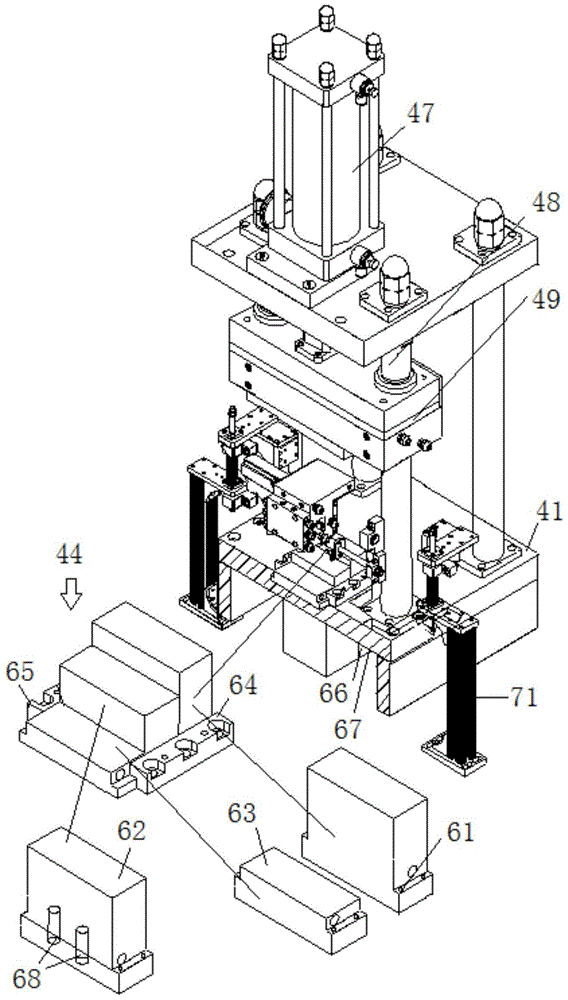

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0054] The structure of the device of the present invention is that the upper electrode pressurizing mechanism, the middle electrode assembly, the clamping mechanism and the lower electrode assembly are arranged in sequence from top to bottom. The middle electrode assembly (or called the mobile floating middle electrode) At least one is installed, and the middle electrode assembly is arranged facing upwards to the upper electrode pressurizing mechanism; the middle electrode 85 in the middle electrode assembly is arranged downwards and aligned with the lower electrode assembly; the clamping mechanism is arranged between the middle electrode assembly and the lower electrode assembly. Between the lower electrode assemblies, the upper electrode, the middle electrode and the lower electrode are respectively connected to the power supply mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com