Reaction chamber and plasma processing device

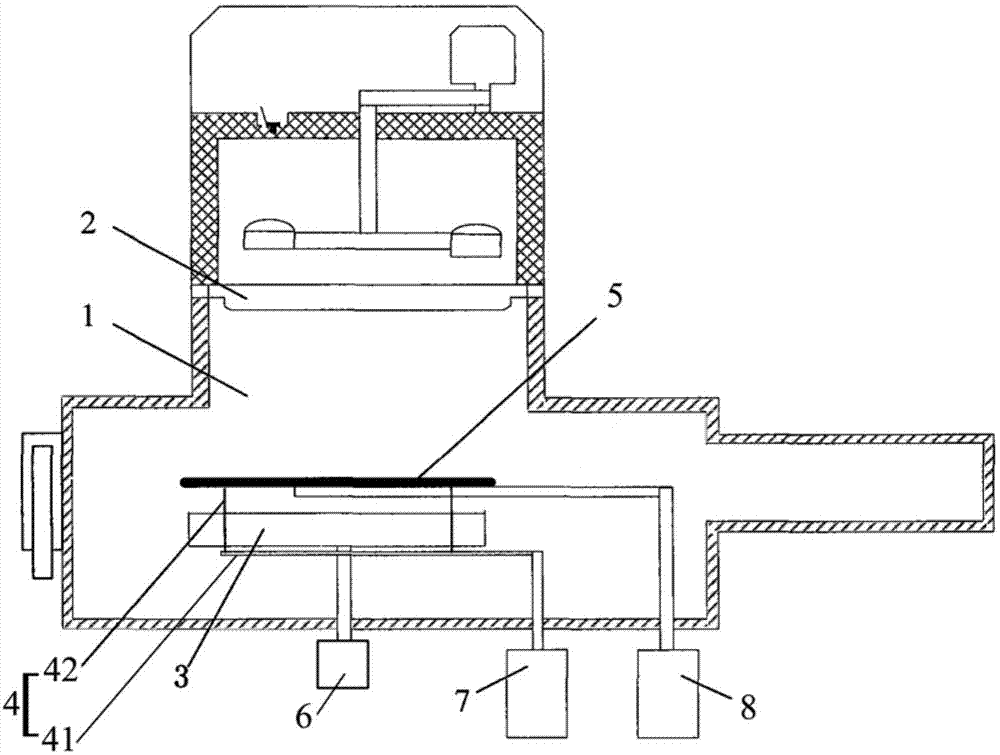

A reaction chamber and plasma technology, which is applied in semiconductor/solid-state device manufacturing, conveyor objects, discharge tubes, etc., can solve problems such as difficulty in guaranteeing verticality of thimble 42, cumbersome debugging process, and influence on levelness, etc., to achieve simple structure , Reduced drive unit, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order for those skilled in the art to better understand the technical solution of the present invention, the reaction chamber and plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

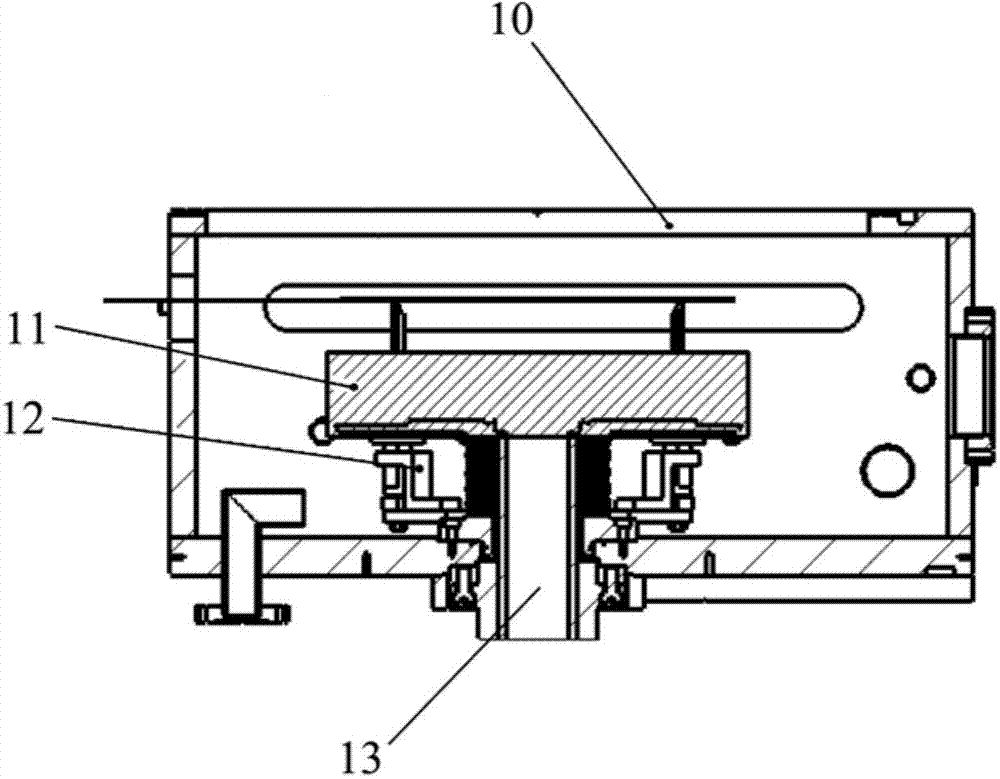

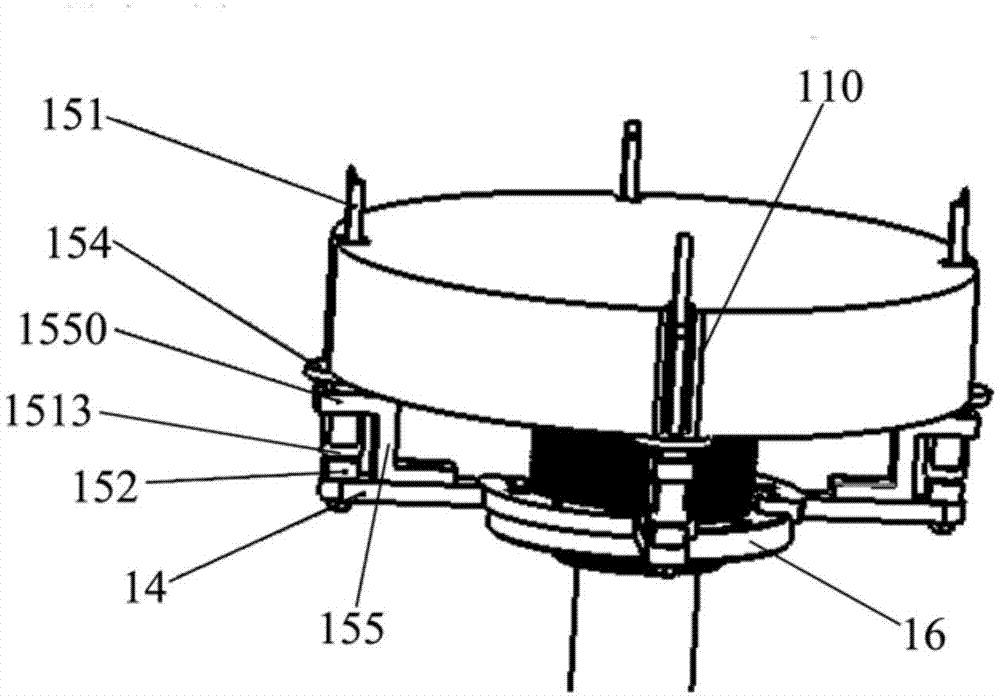

[0036] figure 2Schematic diagram of the structure of the reaction chamber provided by the embodiment of the present invention. image 3 for figure 2 The perspective schematic diagram of the carrying device and the thimble mechanism in the shown reaction chamber. Figure 4 for figure 2 Schematic cross-sectional view of the carrying device and the thimble mechanism in the shown reaction chamber. Please also see figure 2 , image 3 and Figure 4 , the reaction chamber 10 is used to process the workpiece to be processed, and a carrying device 11 and a thimble mechanism 12 are arranged in it. Wherein, the carrying device 11 is provided with a plurality of vertical passages 110, in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com