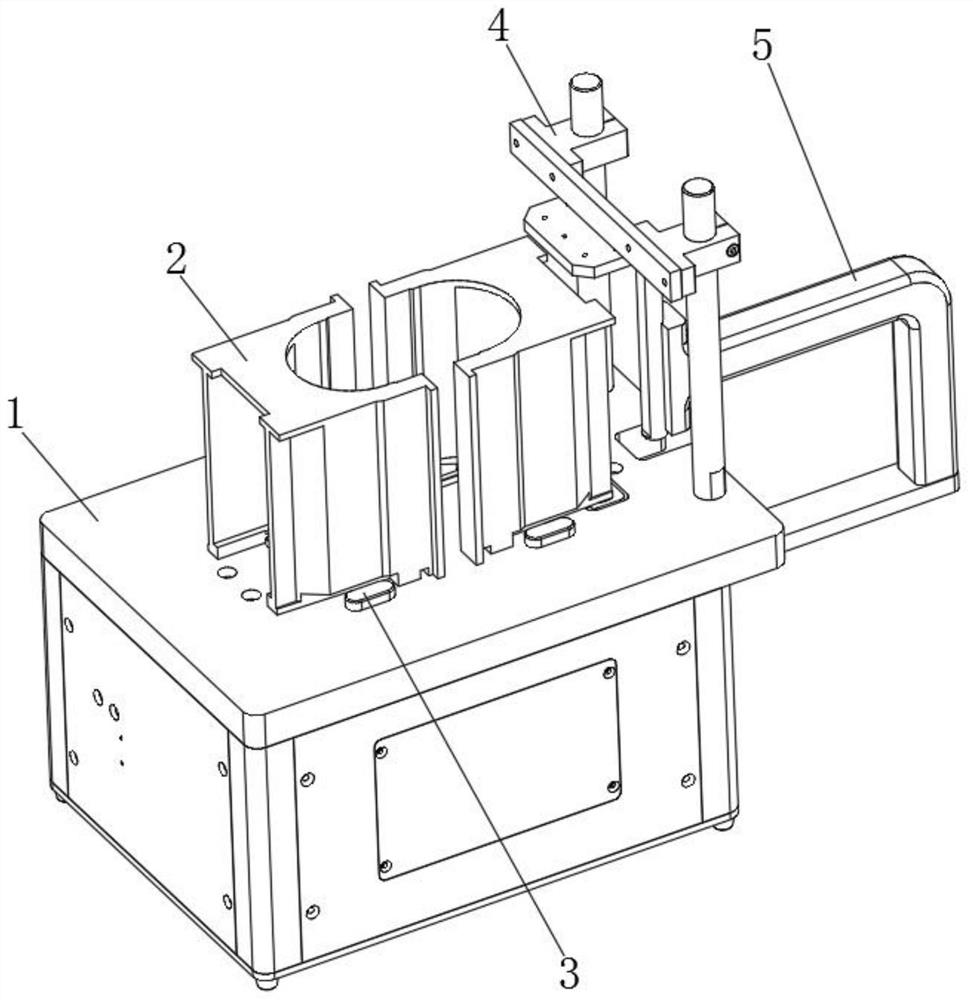

Automatic wafer conveying device

A wafer transfer device and wafer wafer technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of manual transmission force cannot be mastered, labor-intensive, fragmentation, etc., to achieve easy operation, avoid wafer The effect of dislocation of wafers and avoiding damage to transfer wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

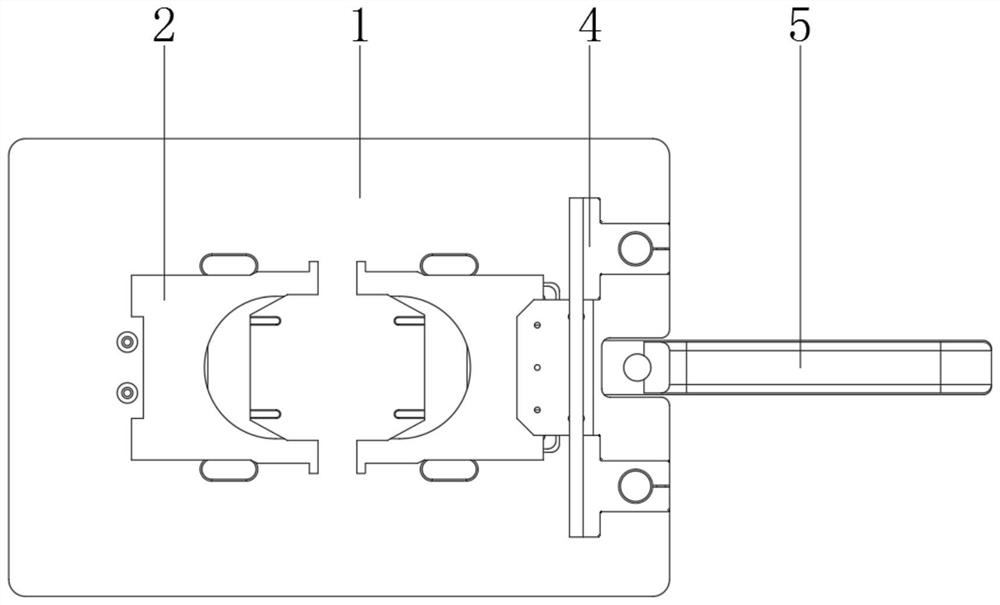

Embodiment 1

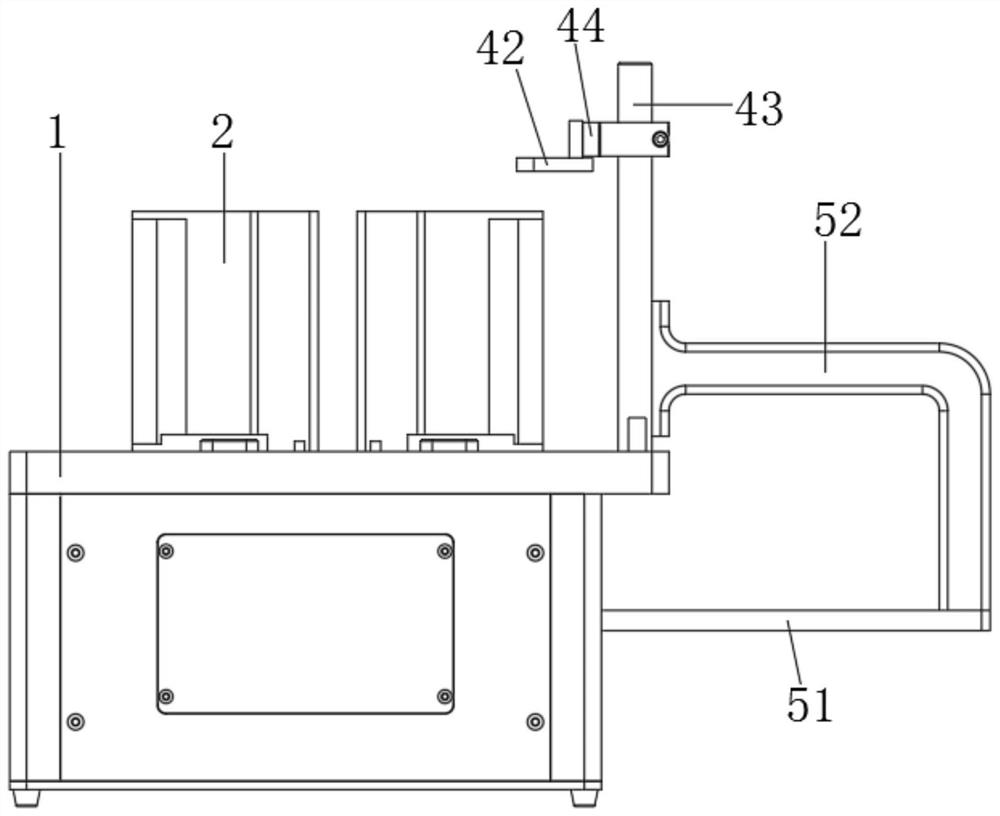

[0038] When the wafer is transferred, the cassette 2 with the wafer and the empty cassette 2 are respectively loaded on the top of the equipment box 1. When installing, the two flat sides 22 at the bottom of the cassette 2 are snapped into the limit position In the gap between the block 32 and the positioning protrusion 31, and make the cassette 2 with the wafer close to the pushing mechanism 5, and make the rib 21 of the cassette 2 snap into the limit groove 33, thereby realizing The horizontal and vertical positioning of the cassette 2, and after the installation of the cassette 2 is completed, the cassette 2 squeezes the positioning cylinder 34, so that the positioning cylinder 34 squeezes the pressure sensor, so that the film transfer device can work normally;

[0039] After the cassette 2 is installed, the infrared transmitter 41 sends an infrared signal. When the infrared receiver 42 receives the signal, the device works normally. When the infrared receiver 42 does not re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com