Manufacture method of HV LED (high voltage light emitting diode) of stereoscopic light emitting structure

A technology of light-emitting diodes and light-emitting structures, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., and can solve the problems of packaging cost reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

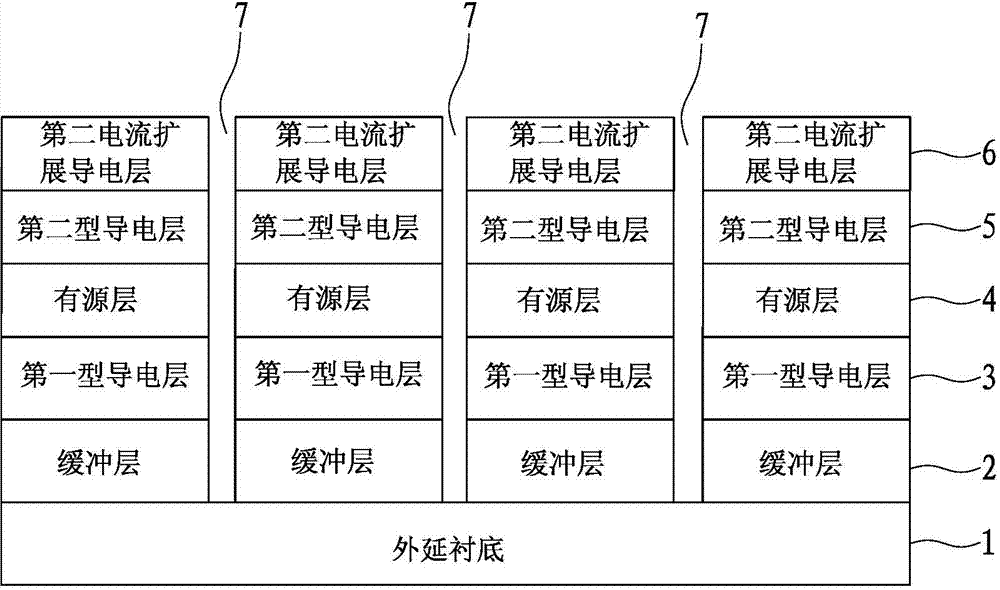

[0124] A high-voltage light-emitting diode with a three-dimensional light-emitting structure, which is composed of seven sub-level light-emitting diodes with independent light-emitting structures connected in series. Each sub-level light-emitting diode in series is divided into two layers, and the bottom layer is composed of four bottom sub-level light-emitting diodes. The top layer consists of three top sub-level LEDs, as Figure 8 shown.

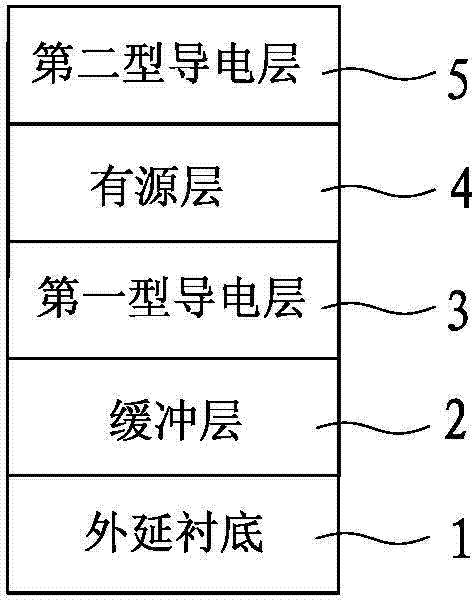

[0125] Each of the sub-level light emitting diodes includes an independent active layer 4 , the first type conductive layer 3 is arranged on the first contact surface of the active layer 4 , and the second type conductive layer 5 is arranged on the second contact surface of the active layer 4 . The first-type conductive layer 3 is made of Si-doped GaN III-V compound, and has a thickness of 2 μm. The active layer 4 adopts a cross-growth structure of 6 pairs of quantum wells and quantum barriers. The quantum barrier is made of GaN III-V co...

Embodiment 2

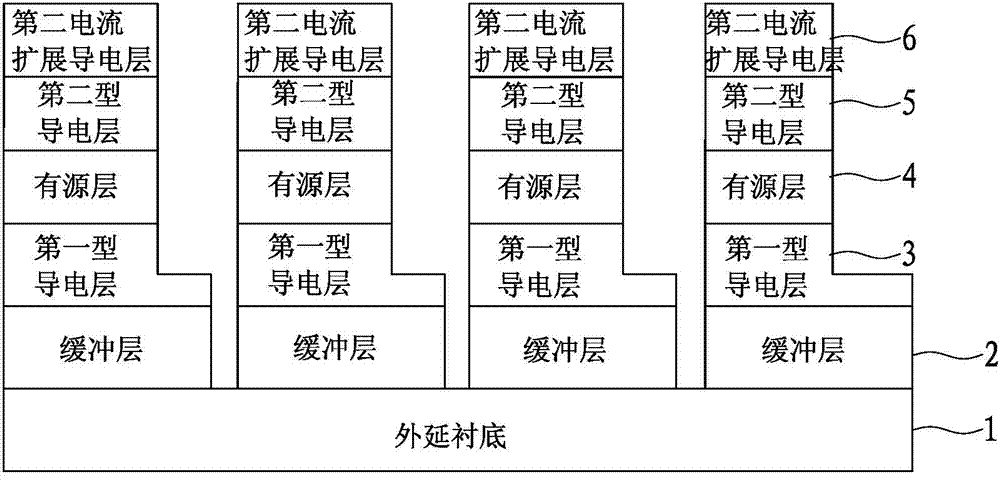

[0151] A high-voltage light-emitting diode with a three-dimensional light-emitting structure, which is composed of nine sub-level light-emitting diodes with independent light-emitting structures connected in series. Each sub-level light-emitting diode in series is divided into two layers, and the bottom layer is composed of five bottom sub-level light-emitting diodes. The top layer consists of four top sub-level LEDs as Figure 22 shown.

[0152] Each of the sub-level light emitting diodes includes an independent active layer 4 , the first type conductive layer 3 is arranged on the first contact surface of the active layer 4 , and the second type conductive layer 5 is arranged on the second contact surface of the active layer 4 . The first-type conductive layer 3 is composed of a first-type current spreading layer and a first-type confinement layer. Specifically, the first type of current spreading layer consists of (Al 0.4 Ga 0.6 ) 0.5 In 0.5 Composed of P-three and five...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com