Sealing structure of power battery top cap and electrode

A power battery and sealing structure technology, which is applied in the direction of sealing materials, structural parts, battery pack parts, etc., can solve the problems of large shrinkage changes of plastic parts, reduced sealing effect of plastic parts, aging of plastic parts, etc., to improve processing efficiency, The effect of reducing assembly procedures and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

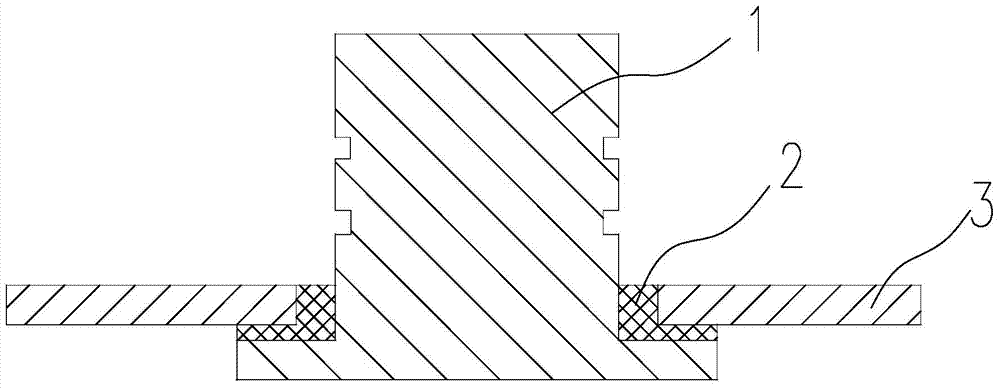

[0020] For the sealing structure of a power battery top cover and electrodes in this embodiment, please refer to figure 1 , including a top cover substrate 3, on which two electrode holes are respectively used to pass through the positive electrode and the negative electrode 1, the inner space of the electrode hole is larger than the positive electrode or the negative electrode 1 and is connected to the positive electrode Or the negative electrode 1 forms an annular gap, and a glass sealing layer 2 is arranged in the annular gap between the electrode hole and the positive electrode or negative electrode 1, and the glass sealing layer 2 is welded together with the top cover substrate 3, the positive electrode, and the negative electrode . The electrode 1 can be made of copper material or aluminum material or composite mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com