Automobile back door structure

A back door and automobile technology, applied in the field of automobiles, can solve the problems of increased vibration noise and friction noise, mismatched body color, high cost of spoiler, etc., to achieve the effect of reducing color difference, ensuring consistency, and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

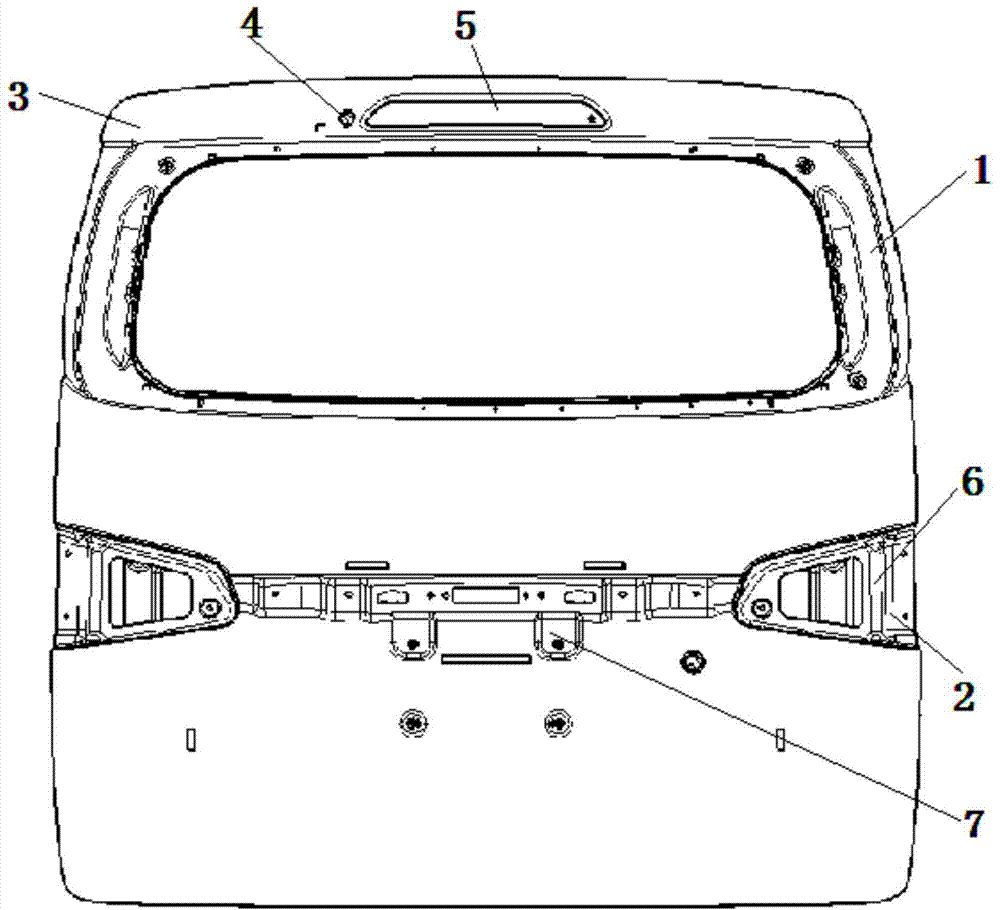

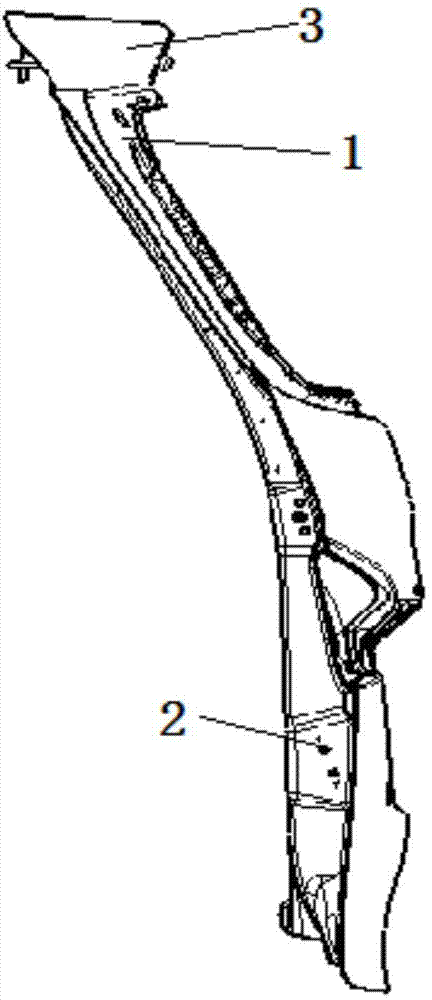

[0019] The automobile back door structure of the present invention, as figure 1 , 2 As shown, it includes a door outer panel 1 and a door inner panel 2, and the door outer panel 1 and the door inner panel 2 are edge-wrapped and connected, and then glued and sealed. The spoiler 3 is arranged on the upper end of the door outer panel 1 and is integrally formed with the door outer panel 1 . That is, the outer door panel 1 of the rear door is punched out of a structure with a spoiler 3 by drawing and forming, and then assembled with the inner door panel 2 to form a rear door assembly. The one-piece rear door structure is produced by using increasingly progressive mold forming technology, which simplifies the production process in the manufacturing process, and can effectively avoid the problem of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com