Short fiber reinforced pultrusion composite material solar module frame and preparation method thereof

A technology for solar modules and short fiber reinforcement, applied in electrical components, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of insufficient structural strength of the frame of solar modules, and achieve the effects of light weight, high efficiency and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

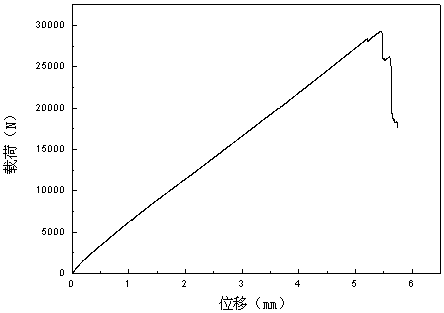

[0028] The frame of the solar module in this embodiment is made by the following methods: (1) Pre-dispersing the short carbon fibers, putting the weighed carbon fibers into water at a temperature of 38-44°C, ultrasonically oscillating with a power of 250W for about 10 minutes, and then adding an appropriate amount of hydroxyl Ethyl cellulose dispersant, stir, continue to ultrasonically vibrate for about 10 minutes, take out and dry for later use; (2) add pre-dispersed short carbon fibers with a volume percentage of 5% into polyurethane with a volume percentage of 25%, Mechanical stirring to obtain a uniform resin mixture; (3) Impregnating the continuous glass fibers impregnated with the coupling agent and drying in the resin mixture, the volume percentage of the continuous glass fibers is 70%; (4) The mold temperature is 180 ° C, The frame of the solar module prepared by the pultrusion injection molding process with the process parameters of the pultrusion speed of 2m / min, the ...

specific Embodiment 2

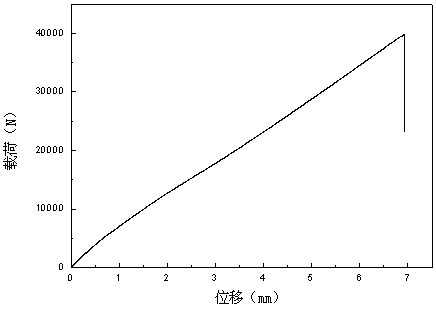

[0029] The frame of the solar module in this embodiment is made by the following method: (1) Add aramid fiber with a volume percentage of 4% and glass short fiber with a volume percentage of 4% into polyurethane with a volume percentage of 22%, and heat and stir A uniform resin mixture is obtained; (2) the continuous glass fibers impregnated with the coupling agent and dried are dipped in the resin mixture, and the volume percentage of the continuous glass fibers is 70%; (3) the mold temperature is 190 ° C, pultrusion The solar module frame profile is obtained by the pultrusion process with the process parameters of the speed of 2.5m / min. The obtained frame stretching curve is as attached figure 2As shown, the strength along the fiber direction is 1071MPa, and the strength in the vertical fiber direction is 230MPa. This frame has high strength and good corrosion resistance and can be used in fields that require high-strength frame materials.

specific Embodiment 3

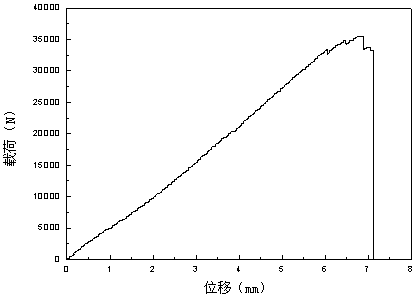

[0030] The frame of the solar module in this embodiment is made by the following methods: (1) Pre-dispersing short carbon fibers, placing the weighed carbon fibers in water with a temperature of 38-44°C, ultrasonically oscillating with a power of 250W for about 10 minutes, and then adding an appropriate amount of hydroxyl Ethyl cellulose dispersant, stir, continue to ultrasonically vibrate for about 10 minutes, take out and dry for use; (2) mix the pre-dispersed carbon short fibers with a volume percentage of 8% and a flame retardant with a volume percentage of 2% Hydrated alumina Al 2 O 3 ·3H 2 O(ATH) was added to polyurethane with a volume percentage of 30%, and a uniform resin mixture was obtained by mechanical stirring; (3) The continuous glass fibers impregnated with the coupling agent and dried were dipped in the resin mixture, and the volume of the continuous glass fibers The percentage is 60%; (4) the solar module frame profile is obtained by the pultrusion process w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com