Integrated electric control system of hydraulic loom

A technology of integrated electric control and water jet looms, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of lack of automatic intelligent functions, troublesome installation and debugging, complicated installation, etc., and achieve clear drive and electrical positions , easy debugging and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

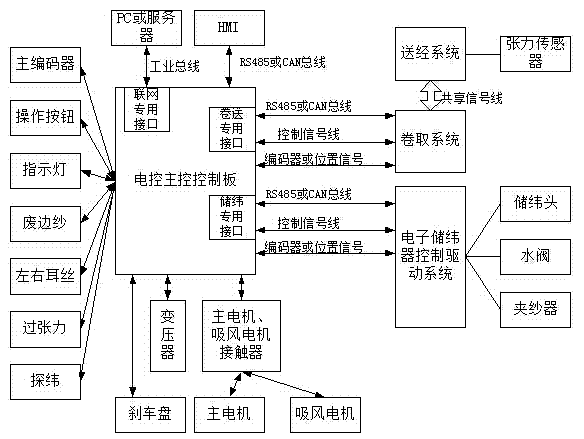

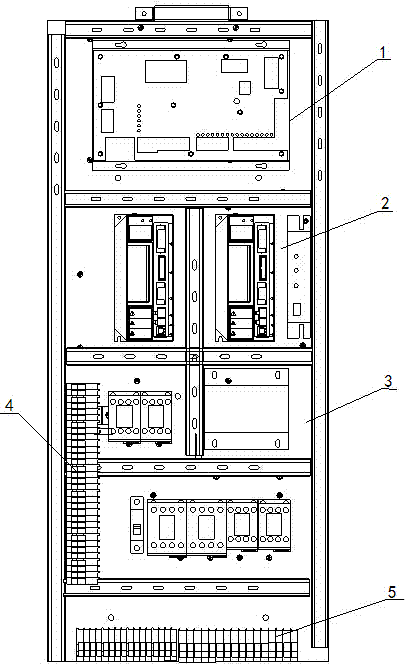

[0029] Such as figure 1 As shown, the water jet loom integrated electric control system described in the embodiment of the present invention includes a main control board 1, an electronic take-up and let-off system 2, an electric unit 3, and an electronic weft feeder system. The interior consists of three parts from top to bottom, among which the main control board 1 is located on the upper part of the box body and this main control board 1 is the control core of the entire loom electric control, which coordinates and controls the operation of the main motor, electronic take-up and electronic warp let-off system, electronic weft feeder system, etc., and has special interfaces for electronic take-up, electronic warp let-off system, and electronic weft feeder system;

[0030] The middle part of the box is the installation position 2 of the electronic take-up and let-off system. This installation position can be flexibly installed with different configurations such as separate el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com