An anti-injection microminiature building template

A technology of building formwork and miniature, applied in the field of building formwork, can solve problems such as panel miniature, and achieve the effect of eliminating injection moulding miniature, increasing the sticking area and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

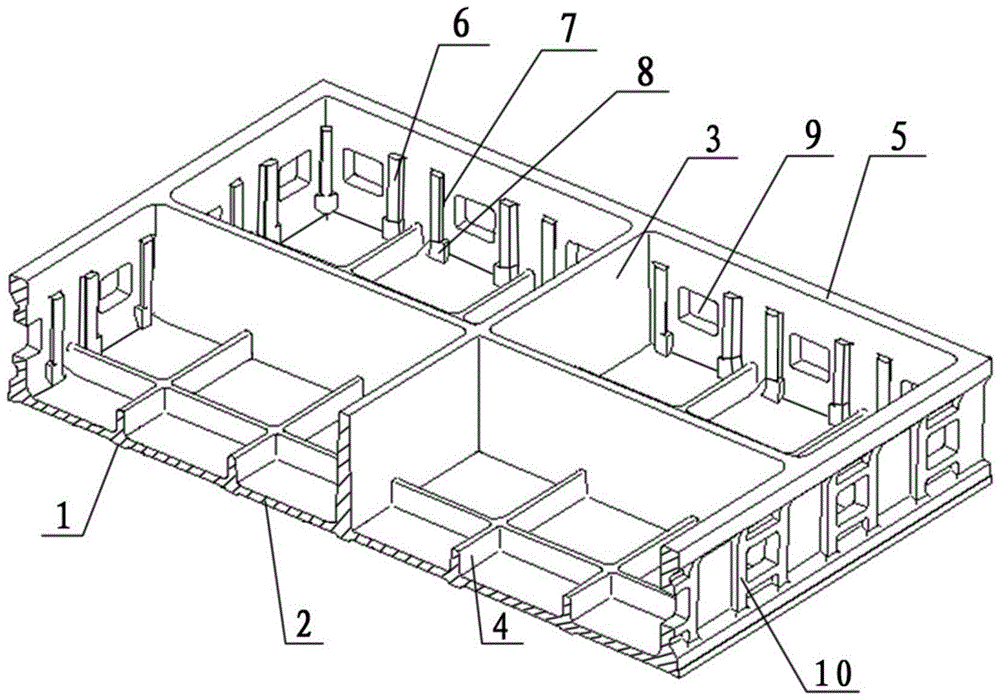

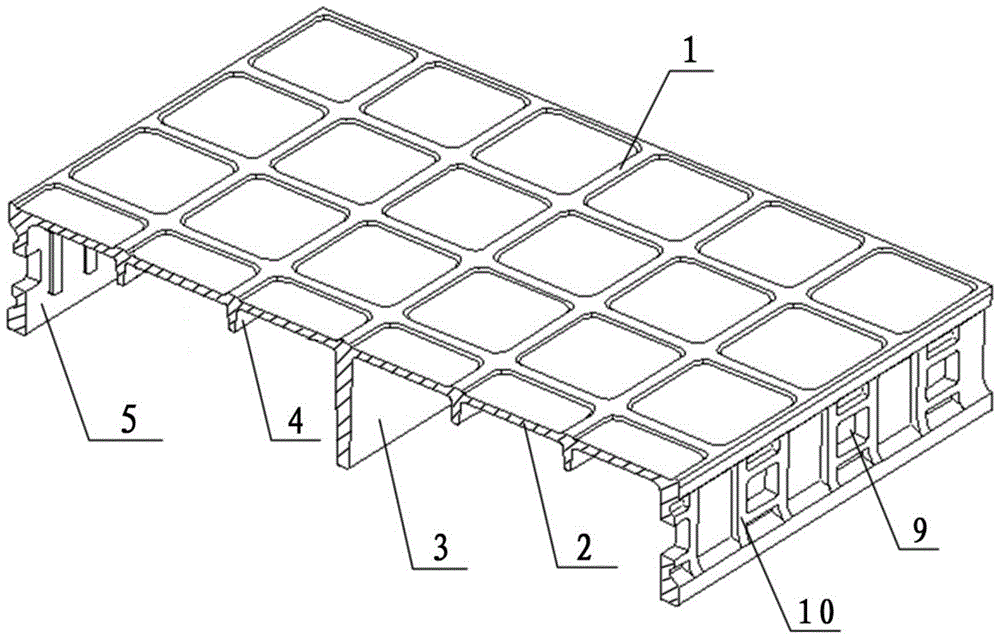

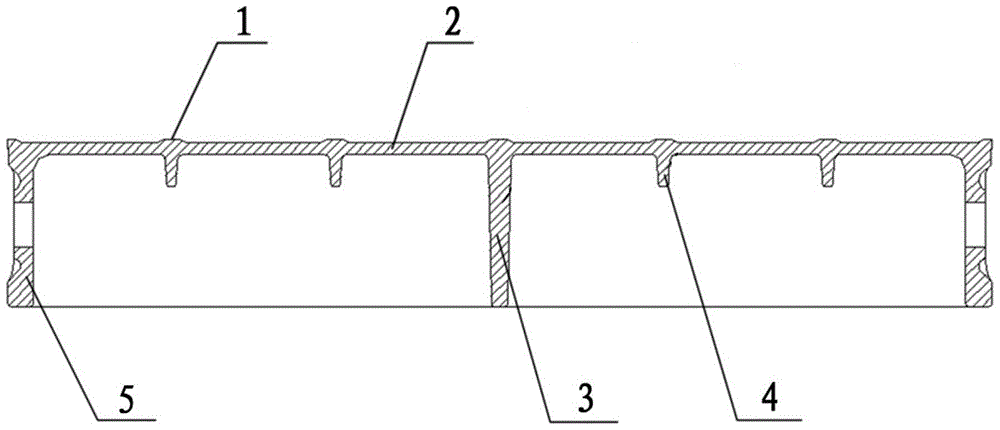

[0019] like Figure 1 ~ Figure 3 As shown, the present invention includes a panel 2, a frame 5, a back rib and a rib 1. The panel 2 is a rectangular plate body, and the panel 2 includes opposite fronts and backs. The front of the panel 2 is the side directly in contact with the concrete to be poured. Connecting hole 9 for connecting with other templates. The back rib is a plate-shaped body, and the back rib is vertically arranged on the back of the panel 2 . The back rib is the keel supporting the panel 2 and is used to enhance the bending resistance of the panel 2 .

[0020] In the present invention, the back ribs include main ribs 3 and secondary ribs 4 . The main ribs 3 and the secondary ribs 4 are vertically arranged on the back of the panel 2 . figure 1 Among them, on the back of the panel 2, the upper edge of the main rib 3 (ie the end away from the panel 2) reaches or approaches the plane where the top surface of the upper edge of the frame 5 (ie the end away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com