Valve internal leakage detecting method based on sonic wave sensors

A technology of an acoustic wave sensor and a detection method, applied in the detection field, can solve the problems of high equipment cost, low detection cost, complex processing, etc., and achieve the effects of high detection efficiency, reduced memory requirements, and reduced complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation of the valve internal leakage detection method based on the acoustic wave sensor of the present invention will be described below with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

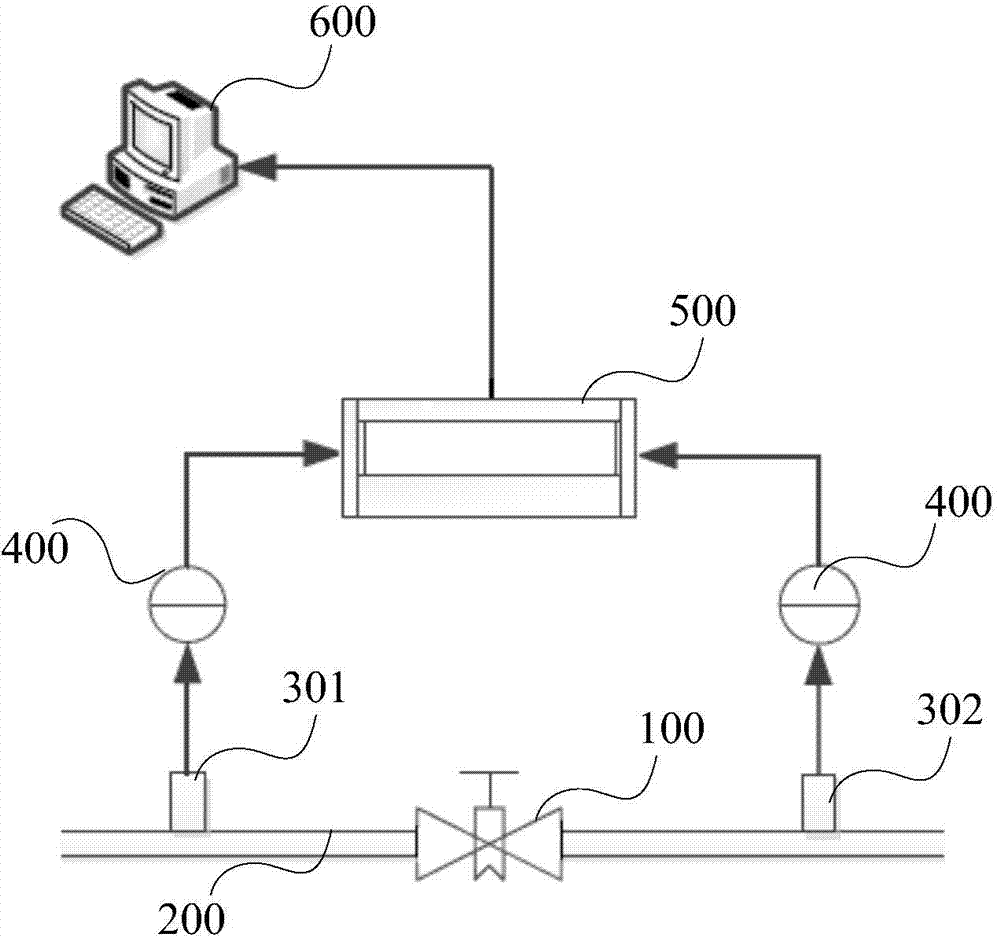

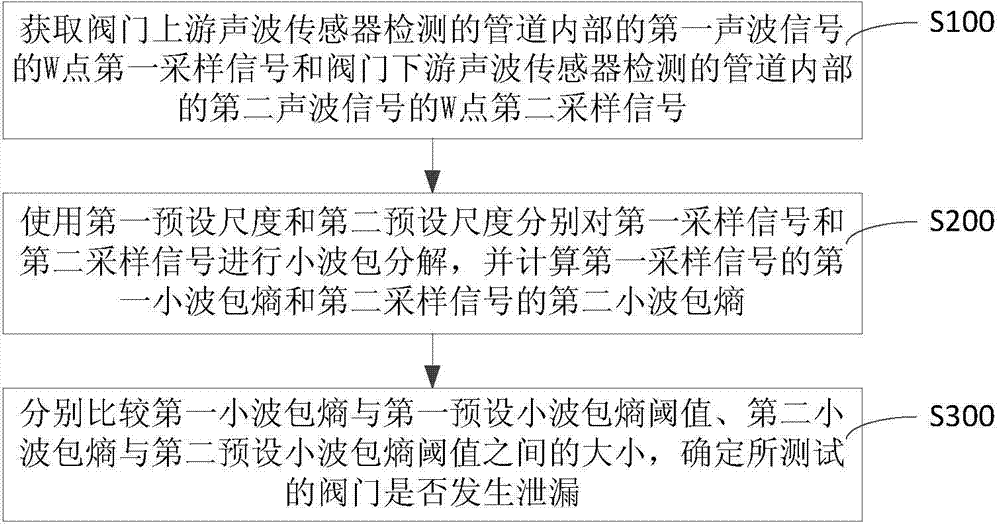

[0036] Valve internal leakage detection method of the present invention is when carrying out valve internal leakage detection, such as figure 1 As shown, the valve 100 to be detected is installed on the pipeline 200, and the valve upstream acoustic wave sensor 301 and the valve downstream acoustic wave sensor 302 are respectively installed on both sides of the valve. Both valve acoustic wave sensors are installed on the outer wall of the pipeline. The acoustic wave sensor 301 upstream of the valve can detect the first acou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com