Hollow radial-magnetic-field permanent magnet opposite-rotating double-rotor compensation pulse electric generator

A radial magnetic field and compensation pulse technology, applied in electrical components, electromechanical devices, etc., can solve the problems of increasing the system volume, parallel current synchronization, doubling, etc., to achieve a simple motor control system, reduced volume, and reduced torque impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

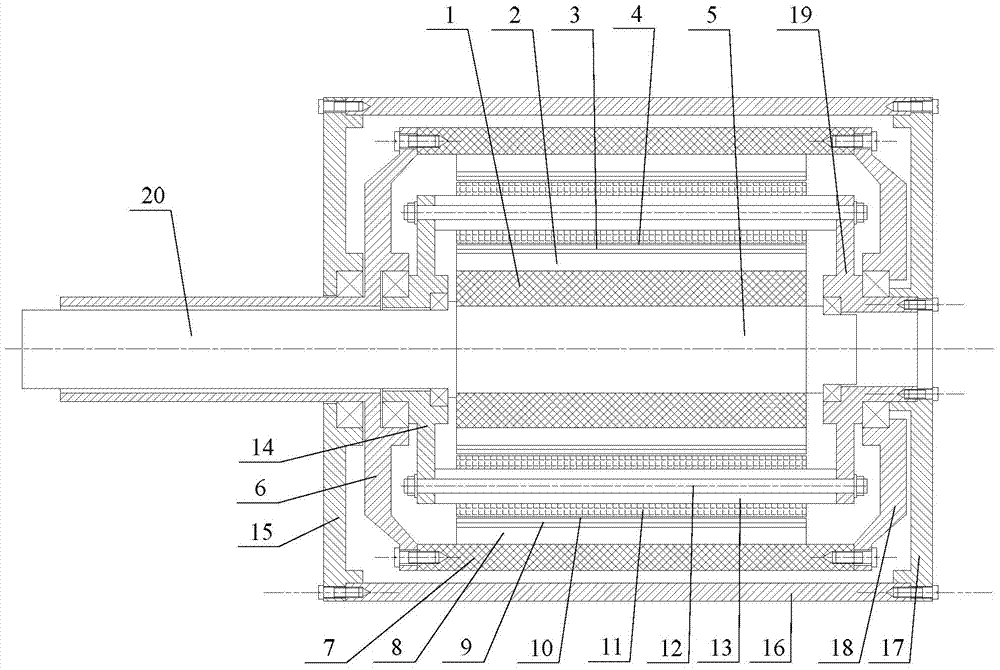

[0029] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the hollow radial magnetic field permanent magnet counter-rotating dual-rotor compensation pulse generator described in this embodiment includes an outer rotor, an inner rotor, a stator, an inner rotor shaft 5, an outer rotor left end cover 6, and a stator left end cover 14 , the left end cover 15 of the casing, the casing 16, the right end cover 17 of the casing, the right end cover 18 of the outer rotor, the right end cover 19 of the stator and the outer rotor shaft 20,

[0030] The outer rotor includes an outer rotor yoke 7, an outer rotor permanent magnet 8, an outer rotor compensation cylinder 9 and an outer rotor bandage 10,

[0031] The inner rotor includes the inner rotor yoke 1, the inner rotor permanent magnet 2, the inner rotor compensation cylinder 3 and the inner rotor bandage 4, the stator package

[0032] Including stator armature winding 11, stator connector 1...

specific Embodiment approach 2

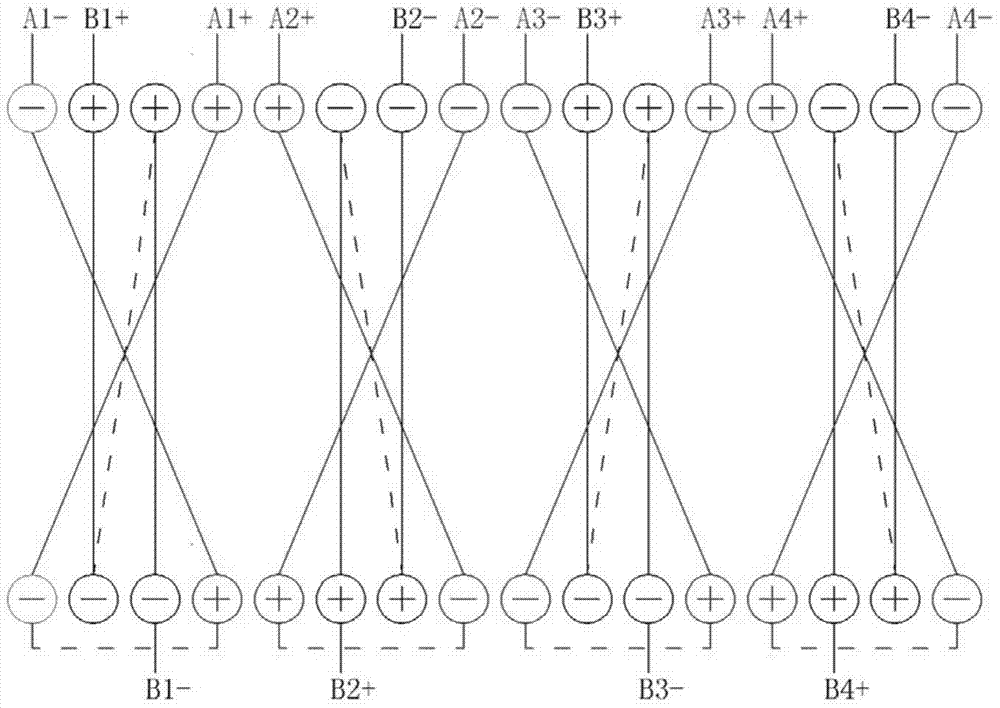

[0040] Specific Embodiment 2: In this embodiment, Embodiment 1 is further described. The inner rotor permanent magnet 2 and the outer rotor permanent magnet 8 are Halbach permanent magnet array structures.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment further describes Embodiment 1 or 2. The air-gap magnetic density generated by the inner rotor permanent magnet 2 and the outer rotor permanent magnet 8 is radial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com