Automatic woofer production method and production line based on PLC

An automatic production method and technology of automatic production lines, which are applied in the direction of program control, sensors, electrical components, etc. The effect of high precision and large transmission load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

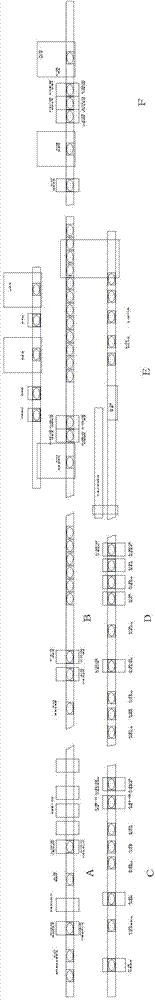

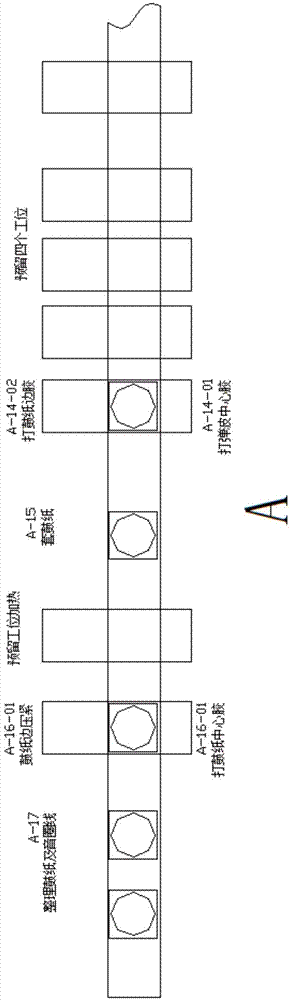

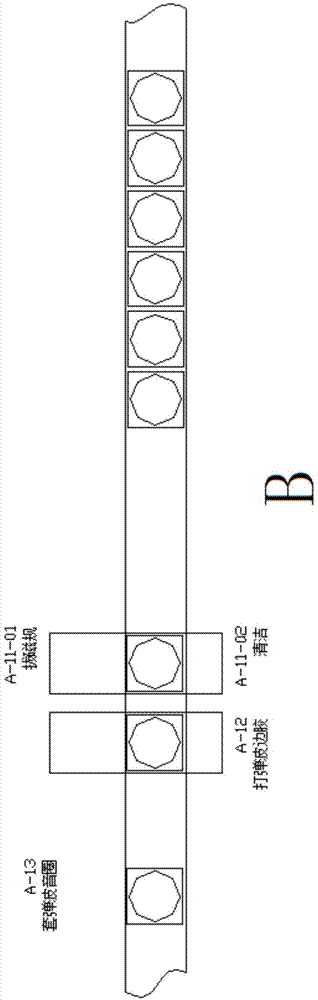

[0062] Example: see Figure 1 to Figure 7 , the present embodiment provides a PLC-based woofer automatic production method, which includes the following steps:

[0063] (1) Set up a double-layer reflow structure with the main return flow in the form of an "H", which includes a left production line, a right production line and a horizontal transfer section connecting the left and right production lines, and a PLC control device is installed on the double-layer return flow structure ;The upper layer is the assembly material glue curing and return conveyor line, and the lower layer is the work station transmission line;

[0064] (2) At the rear end of the left line of the double-layer reflow structure in step (1), set up a PLC automatic feeding system to automatically supply assembly materials;

[0065] (3) On the lower layer of the left line of the double-layer reflow structure, a PLC automatic assembly production process connected to the automatic feeding system is set, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com