Elastic chuck

An elastic chuck, integrated technology, applied in the direction of chuck, transportation and packaging, can solve the problems of reducing processing quality and processing efficiency, reducing quality, small diameter, etc., to improve processing quality and processing efficiency, easy clamping force. Control, consistent thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are preferred embodiments of the present invention.

[0031] Example.

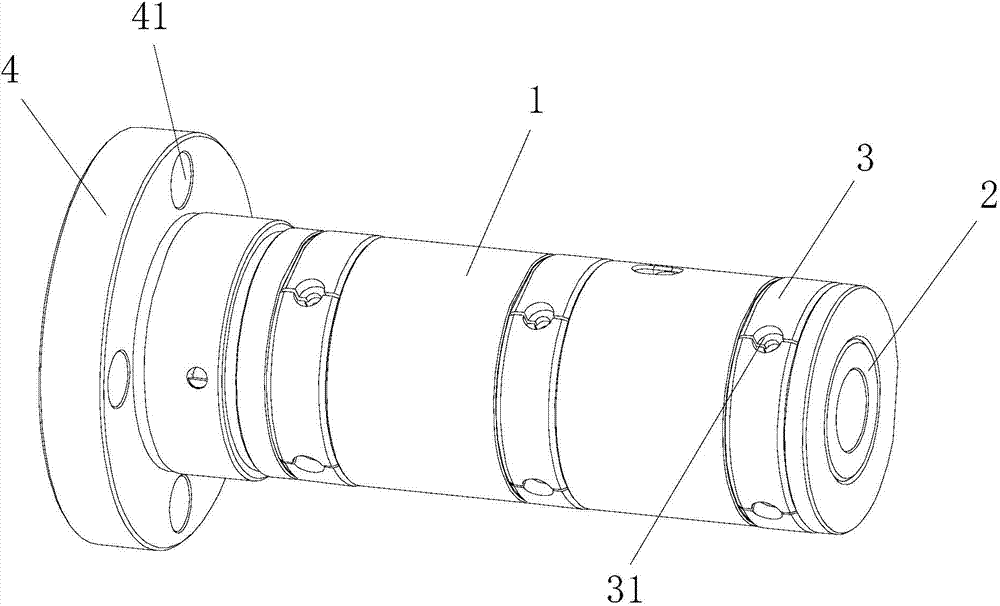

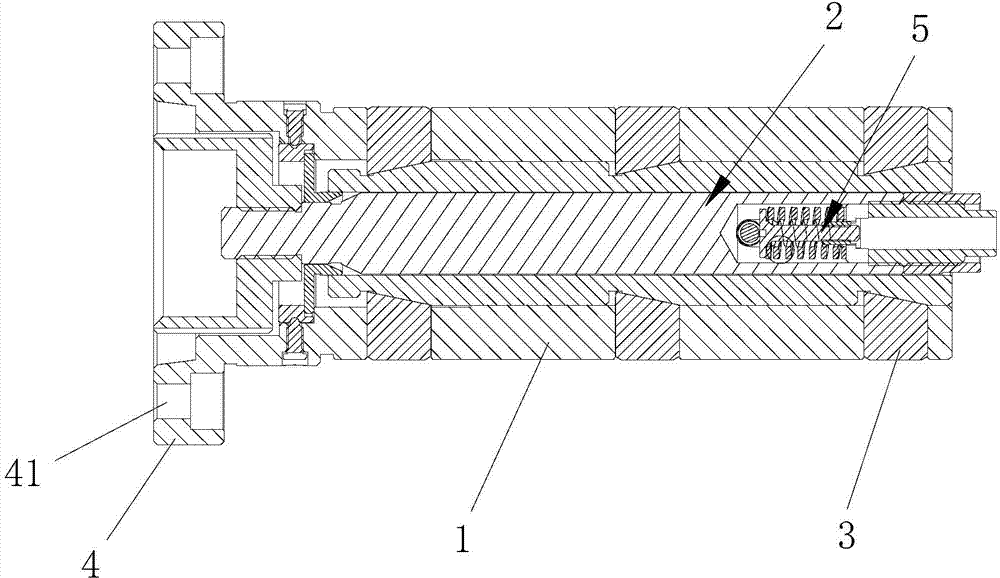

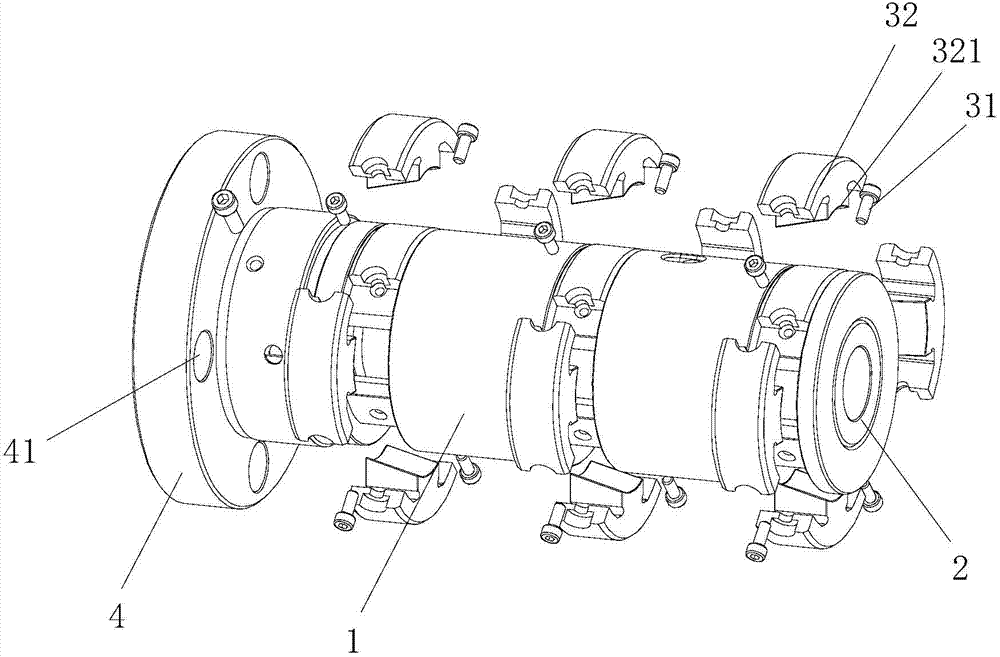

[0032] Such as Figure 1 to Figure 12 As shown, a collet of the present invention includes a cylinder 1, an axial through cavity is arranged in the cylinder 1, a positioning shaft 2 is arranged in the through cavity, and the outer wall of the cylinder 1 is provided with At least two slots 12, each slot 12 is respectively provided with a positioning ring 3, the positioning ring 3 is composed of at least two positioning arcs 32, the two ends of the positioning arcs 32 are respectively connected with the positioning screws 31 and the slots 12 The bottom of the positioning arc 32 is integrally formed with a protruding block 321, and the position of the slot 12 corresponding to the protruding block 321 is provided with a through hole 121, and the through hole 121 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com