A loading platform for processing automobile steering gear shaft parts

A technology for automobile steering gear and parts is applied in the field of loading carriages for the processing of automobile steering gear shaft parts, which can solve the problems of inability to effectively identify the assembly angle, high workpiece rejection rate, high labor intensity, etc., and achieves a simple structure. , The effect of reducing labor intensity and reducing clamping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

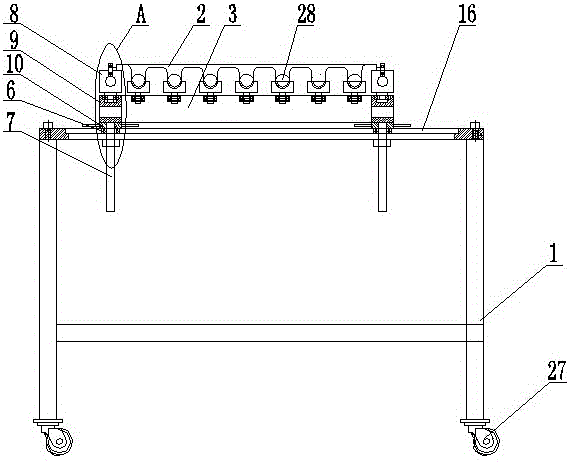

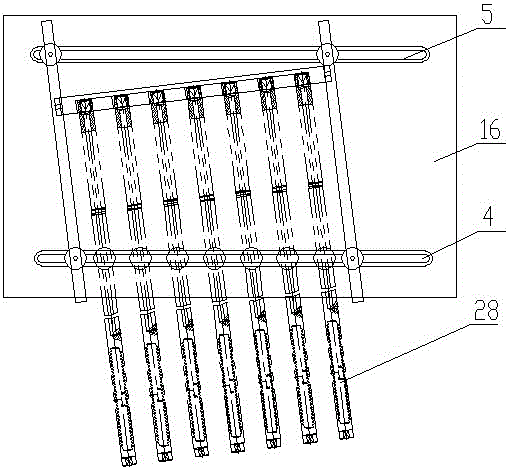

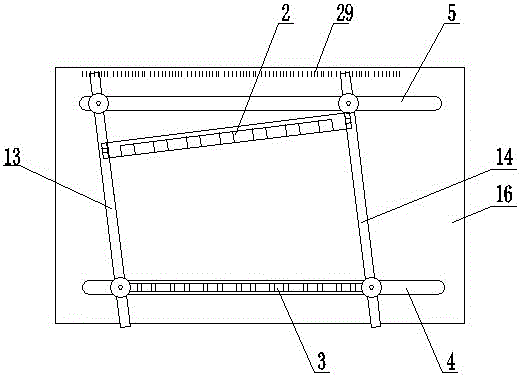

[0025] The loading platform for processing the axle parts of the automobile steering gear includes a bracket 1 , a workpiece limit support plate 2 and a workpiece support plate 3 . The front chute 4 and the rear chute 5 are arranged in parallel on the working panel 16 of the support 1; the working panel 16 at the rear end of the rear chute 5 is provided with an angle scale value 29; the front chute 4 and the rear chute 5 two ends are respectively An adjustment mounting device is installed through the bearing 6 .

[0026] The adjustment installation device is made of support rod 7, upper adjustment block 8, lower adjustment block 9 and adjustment nut 10. Support bar 7 is installed on the work panel 16 of support 1 by bearing 6, and the bottom end of support bar 7 extends to below work panel 16, is provided with locking nut 15 on the support bar 7 extending to work panel 16 below; The top is fixedly equipped with the lower adjustment block 9, and the lower adjustment block 9 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com