Transmission brake integrated device for vehicle

A brake device and integrated device technology, applied in the field of vehicles, can solve the problems of vehicle passability, complex structure, large volume, etc., and achieve the effect of narrow research and development requirements, satisfying structural space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

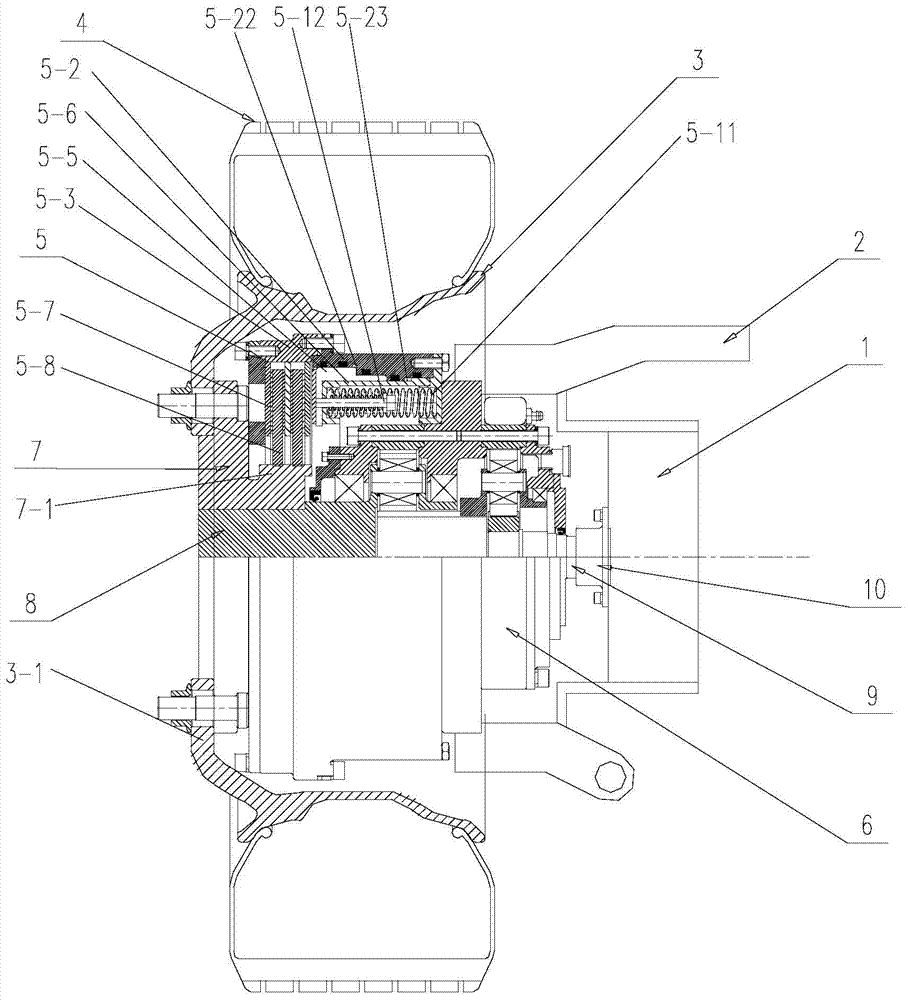

[0017] The basic structure of the vehicle transmission and braking integrated device of this embodiment is as follows: figure 1 As shown, it is mainly composed of a C-section rim 3 located in a vehicle 4 , a brake 5 located in the rim, and a speed reducer 6 .

[0018] One side of the rim 3 has a perforated end plate 3-1 fixedly connected with the output flange 7. The inner side of the output flange 7 radially extends out of the flange flange 7-1.

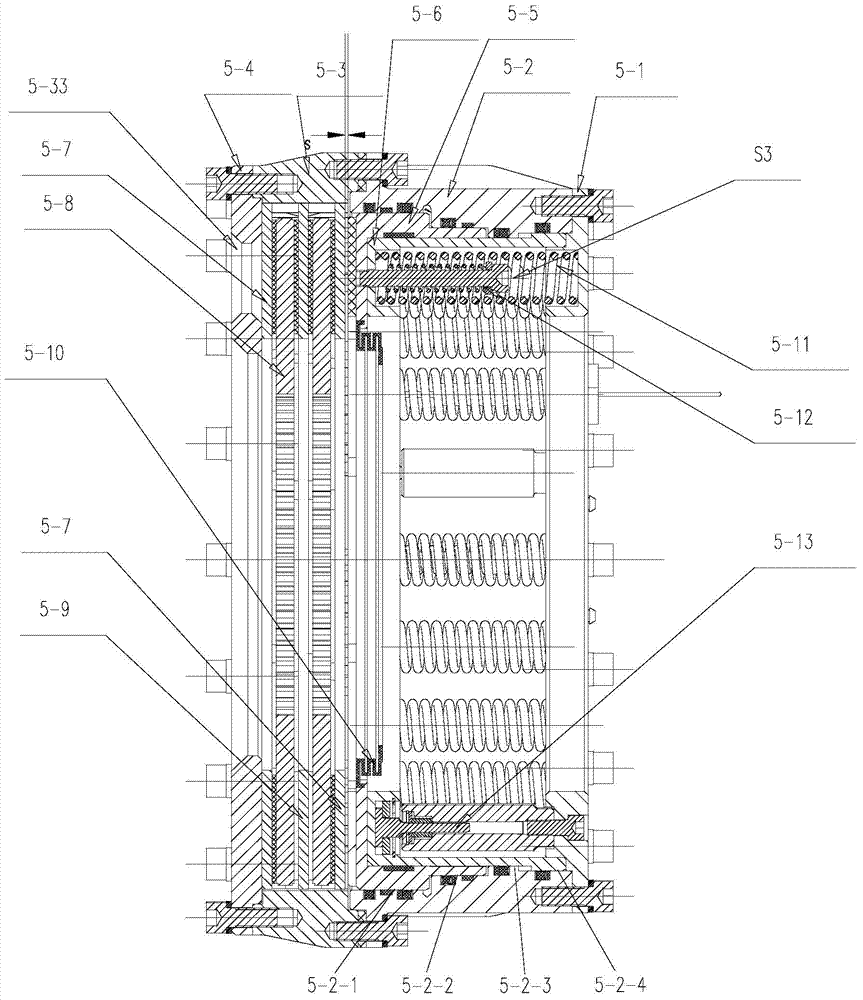

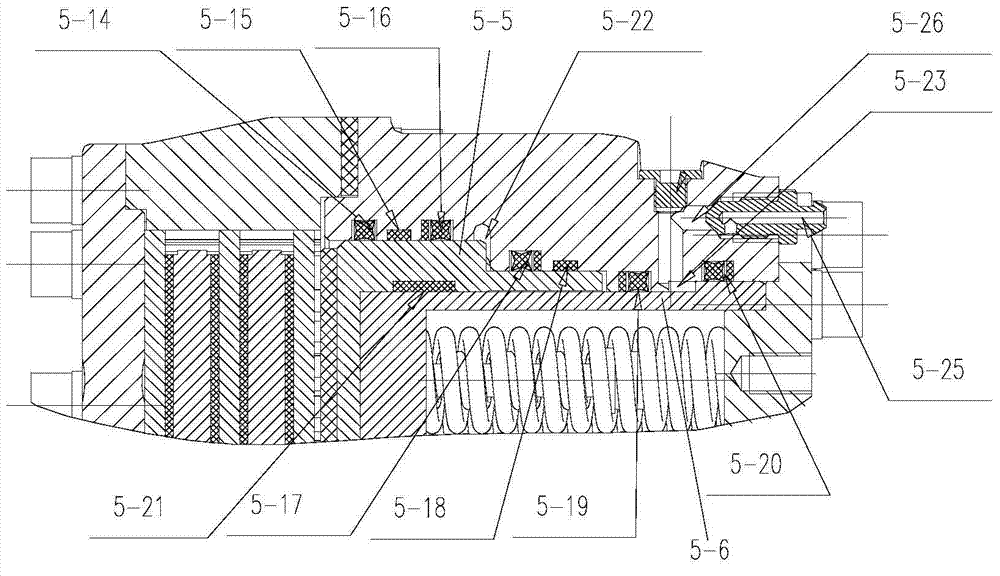

[0019] One end of the brake 5 adjacent to the end plate 3-1 contains a set of outer circles distributed at intervals through the spline structure and the friction plates 5-7 that are circumferentially constrained by the brake housing 5-3 and constitute a moving pair in the axial direction. There is a brake disc 5-8 which is circumferentially constrained by the inner hole through the spline structure and the flange flange 7-1 and constitutes a moving pair in the axial direction. The friction plate and the brake disc constitute a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com