Double-layer jacking transfer machine

A technology of jacking up and transferring and transferring machines, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems that the height cannot meet the requirements, the structural size limit of the jacking transplanter, and the load cannot meet the requirements, etc., and the structure can be achieved. Compact, overall height-reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

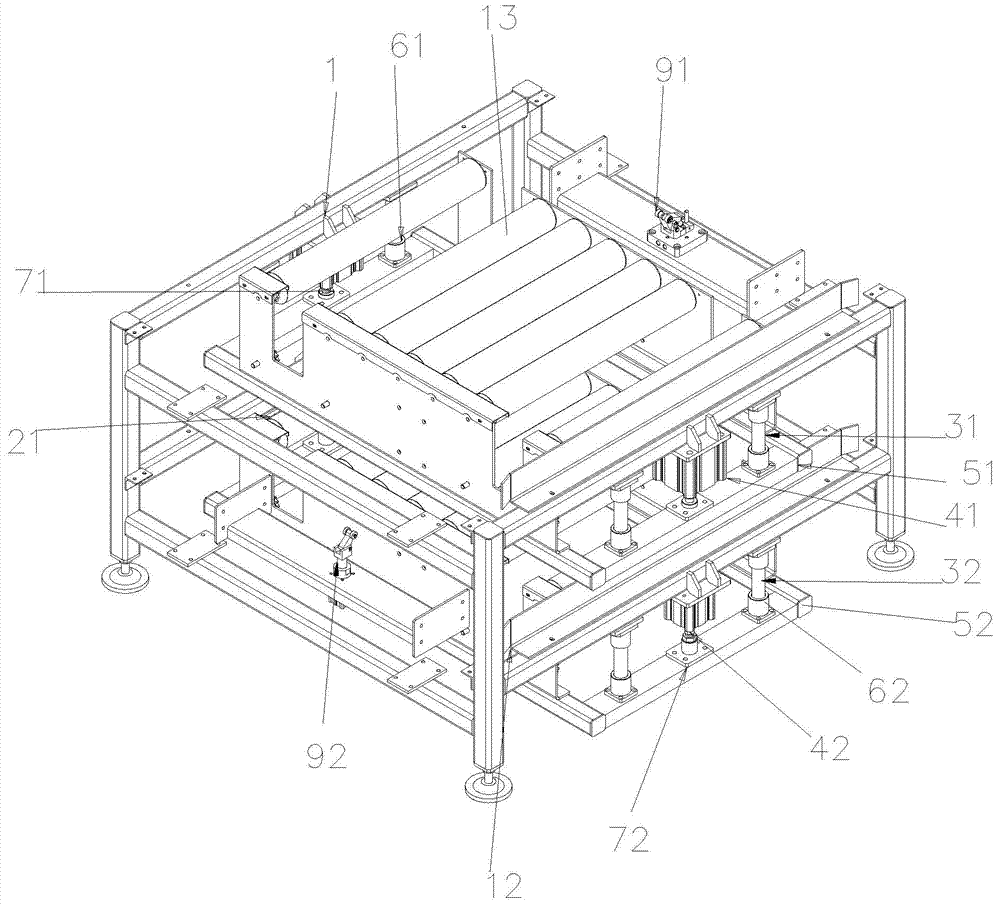

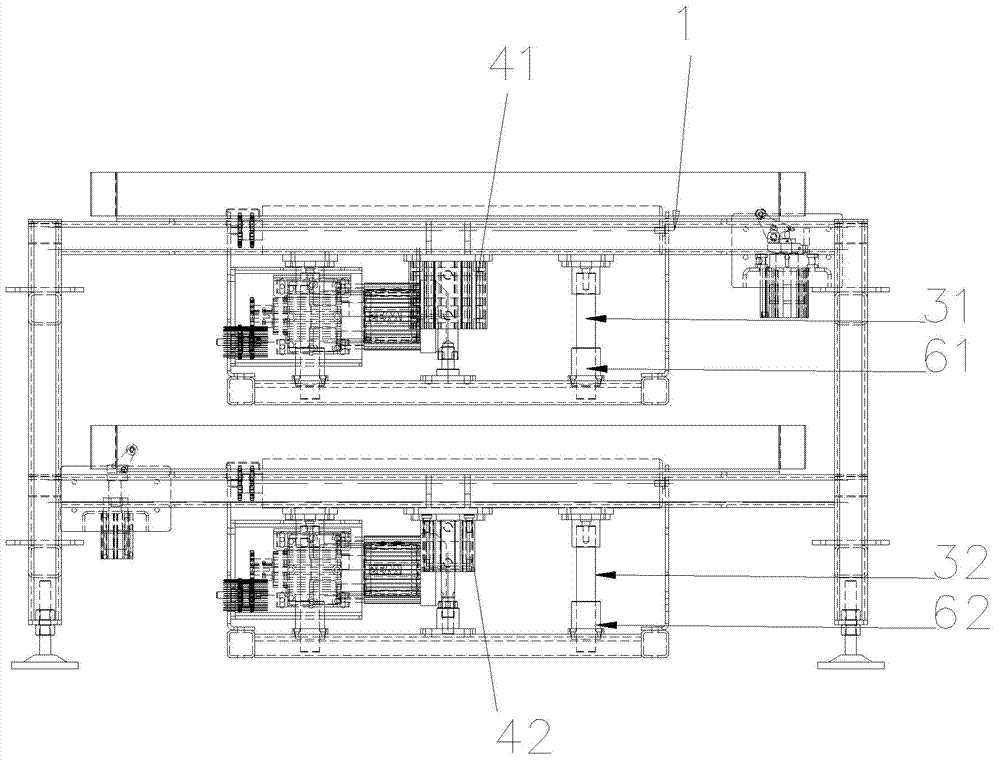

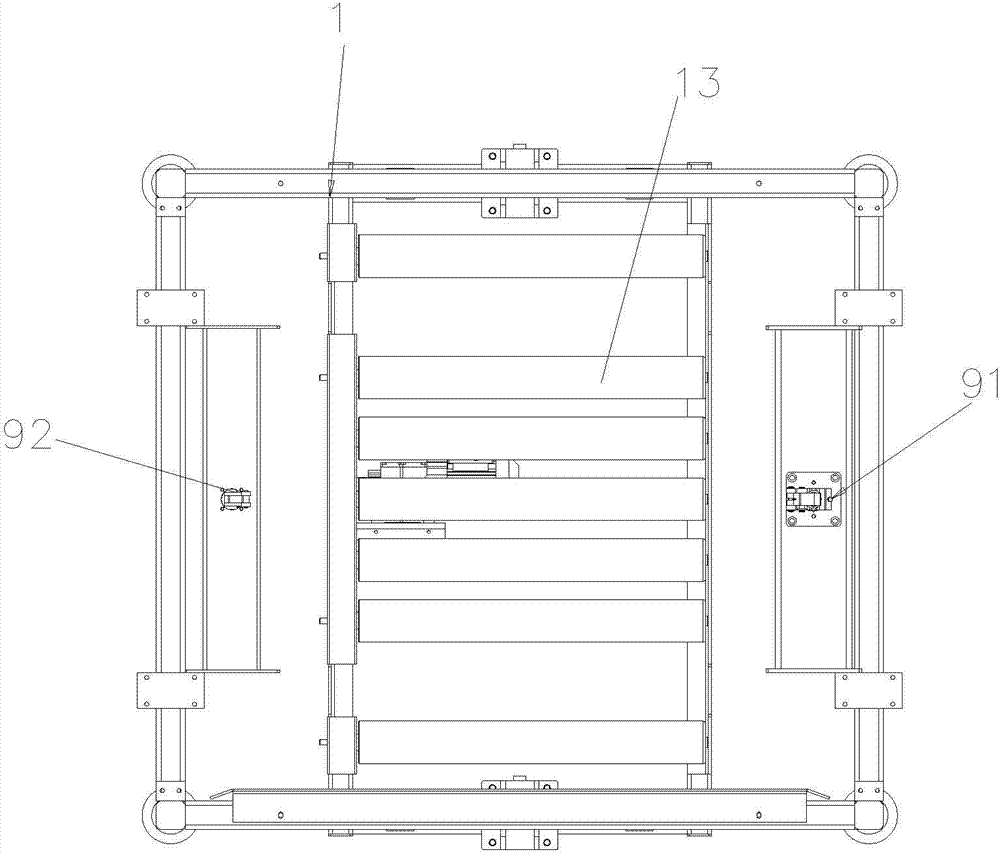

[0020] The structure of the double-deck lifting transfer machine of the preferred embodiment of the present invention is as follows: figure 1 shown, see also figure 2 and image 3 , including the jacking and transferring bracket 1 used in conjunction with the double-layer chain machine 1313; wherein, the jacking and transferring bracket 1 is provided with an upper jacking and transferring machine and a lower jacking and transferring machine, and the lower jacking and transferring machine is set Below the upper layer jacking transfer machine; the upper layer jacking transfer machine includes an upper layer transfer assembly 51, and the upper layer jacking transfer machine also includes two upper layer cylinders 41 for providing jacking power, and the two upper layer cylinders 41 pass through Two upper strata cylinder connection blocks 71 are arranged on the upper strata transfer assembly 51 both sides above, to reduce the overall height of transfer machine; The upper strata t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com