Preparation process of medical ti‑6al‑7nb alloy wire for manufacturing Kirschner wires

A technology of ti-6al-7nb and alloy wire, which is applied in the field of titanium alloy preparation, can solve the problems of high price and difficult alloy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

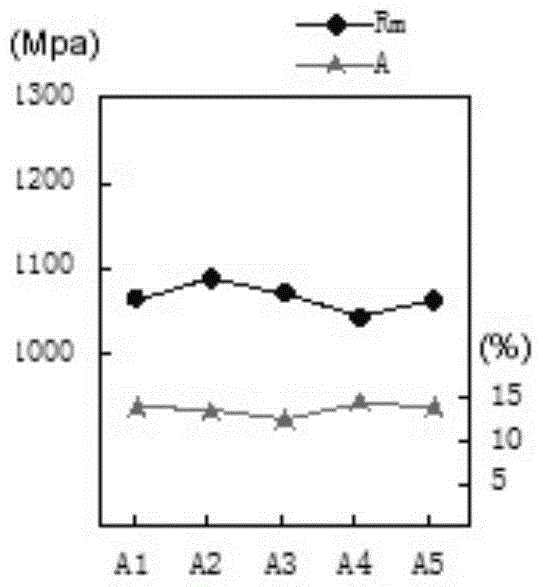

[0031] The medical Ti-6Al-7Nb alloy wire production process that is used to manufacture Kirschner wire, it implements according to the following steps:

[0032] (1) Melting ingot

[0033] Use "0" grade special sponge titanium as raw material, use pure Al beans and pure Nb lath as alloy elements, according to the famous alloy composition of Ti-6Al-7Nb grade, press electrode group welding, and smelt three times in vacuum consumable electric arc furnace into ϕ370*Lmm alloy ingot;

[0034] (2), blank forging

[0035] The ingot is heated to the β-phase area by an electric furnace, and it is kept warm to make it completely burnt through (reaching a heat conduction speed of 0.6-0.7mm / min). Under the high pressure of a 2,500-ton hydraulic press, the large deformation (three upsetting and three pulling) reaches 200*200mm square, surface defects Grinding, and then forging to ϕ80*Lmm round billet (deformation greater than 60%).

[0036] (3), hot rolling

[0037] The ϕ80*Lmm round bil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com