A method for producing ultra-wide aluminum alloy profiles for train freight car bodies beyond the capacity of equipment

A technology for aluminum alloy profiles and equipment capabilities, which is applied in the field of ultra-wide aluminum alloy profiles for train freight car bodies, can solve problems such as large increase in strength and large deformation resistance, and achieve improved mechanical properties, comprehensive performance, and beautiful gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

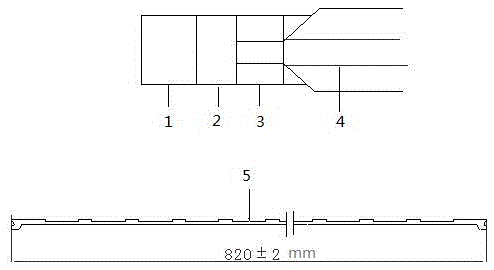

[0023] 1. Selection of extrusion machine, mold design, the traditional design is produced on a 125MN or 90MN extrusion machine, and the production of ultra-wide aluminum alloy profiles for train freight car bodies with a circumscribed circle diameter of 820.07mm;

[0024] 2. The cast aluminum alloy is a six-series aluminum alloy round ingot. The traditional ingot size is Φ600mm×4000mm. The No. 6 aluminum alloy round ingot is melted. The mass percentage of the elements in the aluminum alloy ingot used is 0.70% Si and Fe is 0.58%, Cu 0.33%, Mn 0.138%, Mg 1.12%, Cr 0.27%, Zn 0.18%, Ti 0.10%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the rest is Al; ingredients It is required to calculate ingredients, liquid slag removal and degassing during casting, and filtration is required during casting. The calculation of ingredients is based on the center line of step 2 to ensure that the composition of the ingot is controlled within the standard range; Slag removal, slag removal onc...

Embodiment 2

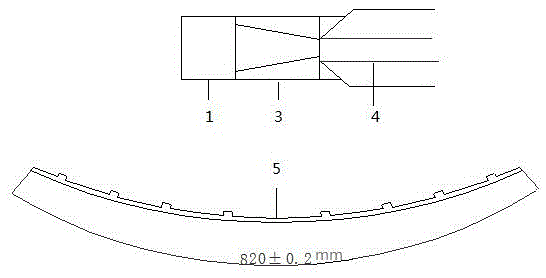

[0030] The difference between this embodiment and the specific embodiment 1 is that a 75MN extruder is used to design an ultra-wide aluminum alloy profile for a train freight car body by using an expansion die, and the straight profile is designed into a curved profile, and the diameter of the circumscribed circle is Ф460mm Extrusion cylinders produce ultra-wide aluminum alloy profiles for train and freight car bodies with a circumscribed circle diameter of 820.07mm, breaking the industry’s regulation that the diameter of the extrusion cylinder is 10-20% larger than the circumscribed circle diameter of the product. Other steps and parameters and specific implementation methods 1 same.

Embodiment 3

[0032]The difference between this embodiment and specific embodiment 1 is that the cast aluminum alloy ingot is a No. 6 aluminum alloy round ingot, and the mass percentages of the elements in the aluminum alloy ingot used are 0.72% for Si, 0.45% for Fe, and 0.45% for Cu. 0.33%, Mn 0.139%, Mg 1.12%, Cr 0.27%, Zn 0.15%, Ti 0.11%, single impurity ≤ 0.05%, total impurity ≤ 0.15%, the rest is Al;

[0033] Slag removal once after melting, once after refining in smelting furnace, once after refining in holding furnace; degassing once after refining in smelting furnace, once degassing after refining in holding furnace, and degassing by degasser after refining in holding furnace gas. The degree of refining meets the requirements of the first-level oxide film, there is no segregation of metal and non-metallic compounds, and the quality of the melt is guaranteed to be uniform. The wide aluminum alloy profile breaks suddenly due to structural defects, and other steps and parameters are t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com