Gas and coal spontaneous combustion coupling disaster monitoring system and monitoring method in coal mine stope

A monitoring system, coal spontaneous combustion technology, applied in mining equipment, measuring equipment, mining equipment, etc., can solve problems such as inability to guide on-site disaster prevention and control, lack of monitoring means, and inability to display the distribution range of goaf coupling disasters, etc. , to achieve the effect of wide practicability, simple process and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

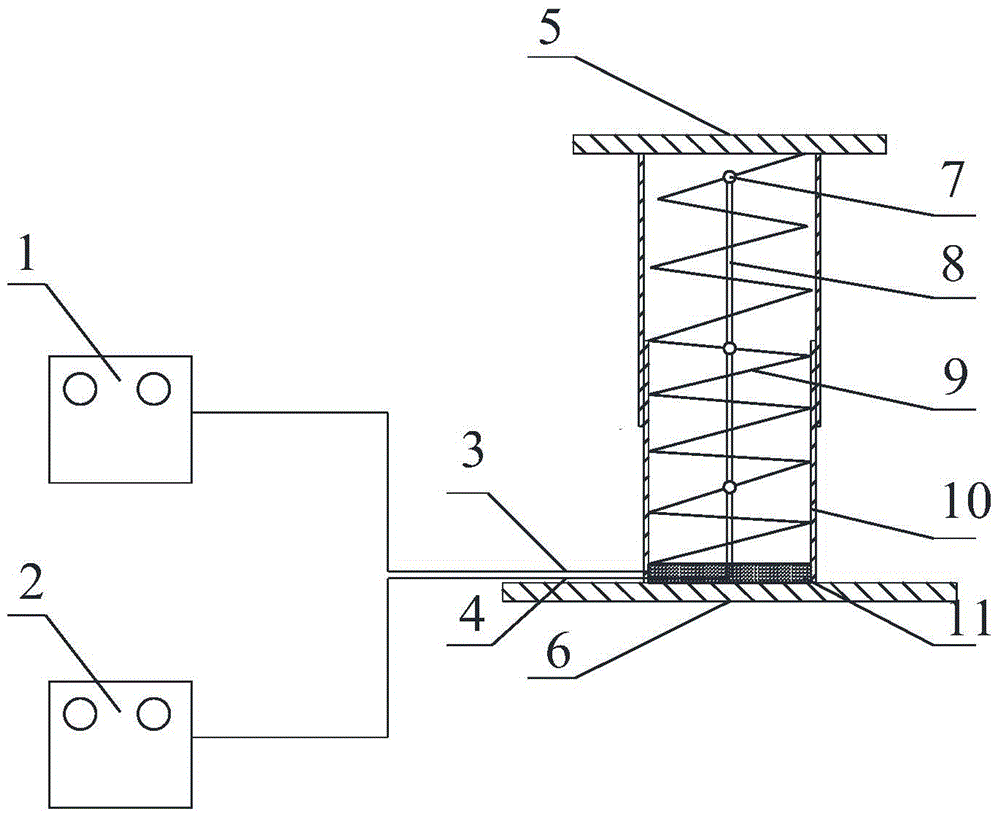

[0055] The present invention will be further described in detail below with an application example of a certain working face in a certain mine.

[0056] The parameters of the working face are the strike length of 100m, the average coal thickness of 6.3m, the mining height of 3m, the average mining and laying ratio of 1:1.1, and the pressure step distance of the working face of 12m. 100m.

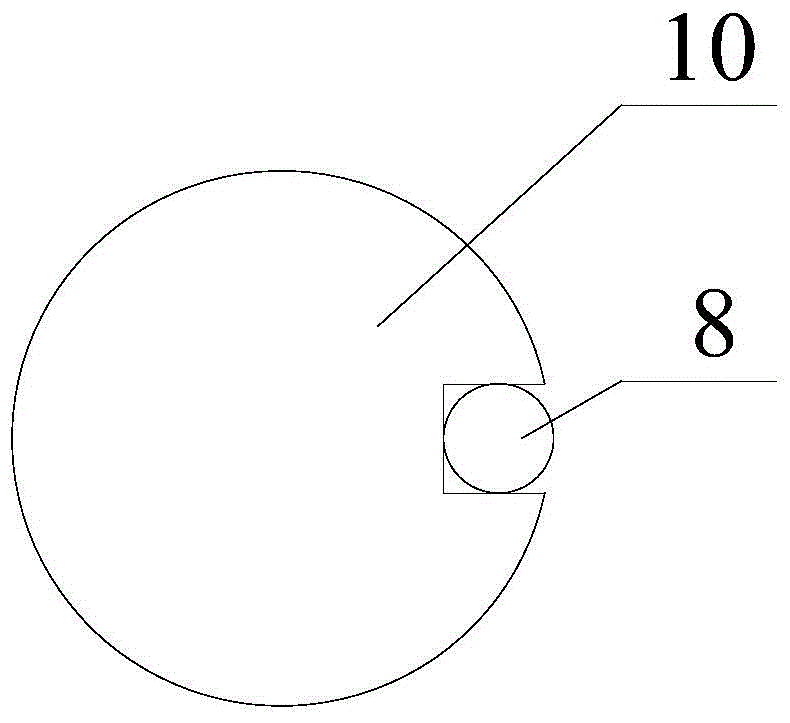

[0057] After calculation, the thickness of the remaining coal in the goaf at the back of the working face is 1.01m, and the thickness of the mixed zone is 0.58m. Therefore, the parameters of the gas sampler can be designed as:

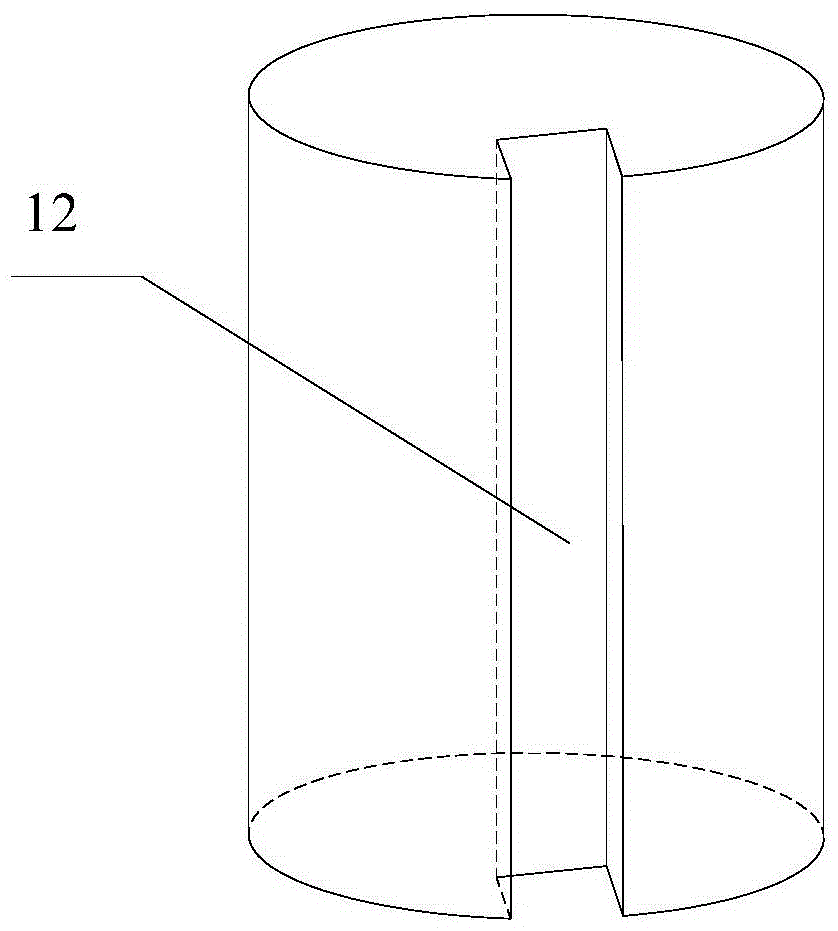

[0058] The length of the upper seamless steel pipe is 800mm, the inner diameter is 150mm, and the wall thickness is 3mm;

[0059] The length of the lower seamless steel pipe is 800mm, the inner diameter is 144mm, and the wall thickness is 3mm;

[0060] The diameter of the lower steel pipe tray is 250mm, the diameter of the upper seamless steel pipe tray is 160mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com