Method and system for on-line monitoring of gas in multi-channel air sampling type inspection shaft

An air sampling and monitoring system technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as inability to form online monitoring of gas pipeline leakage, difficulty in power supply to alarms, and no signal transmission function involved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

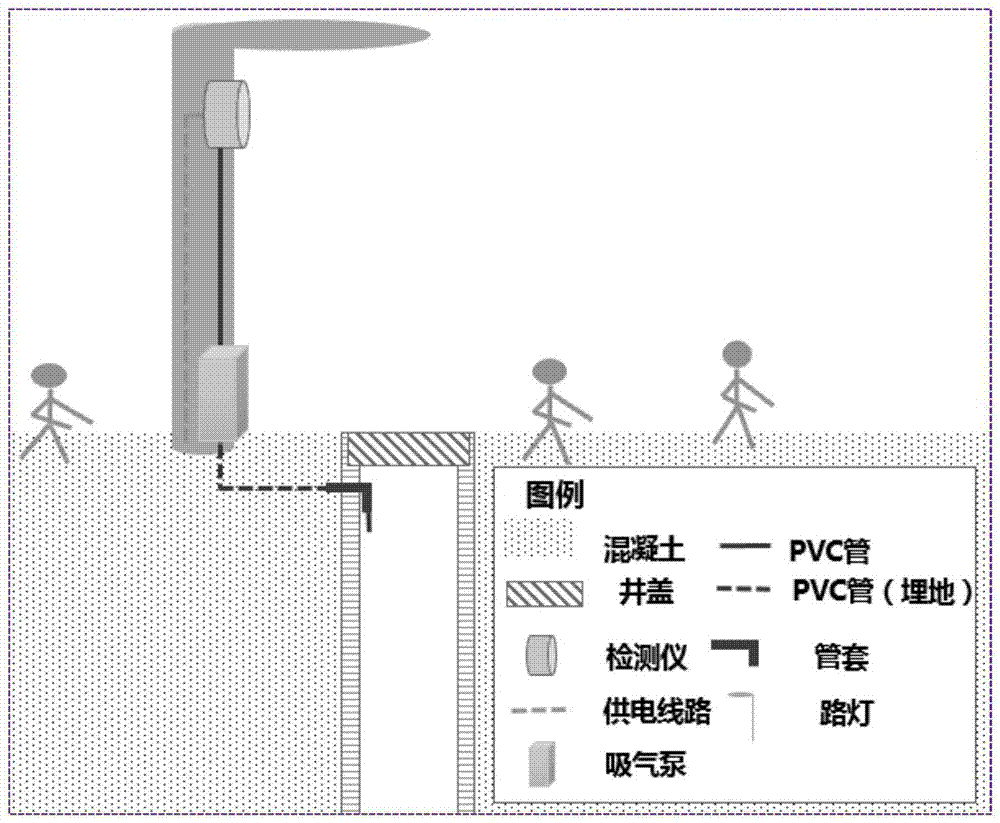

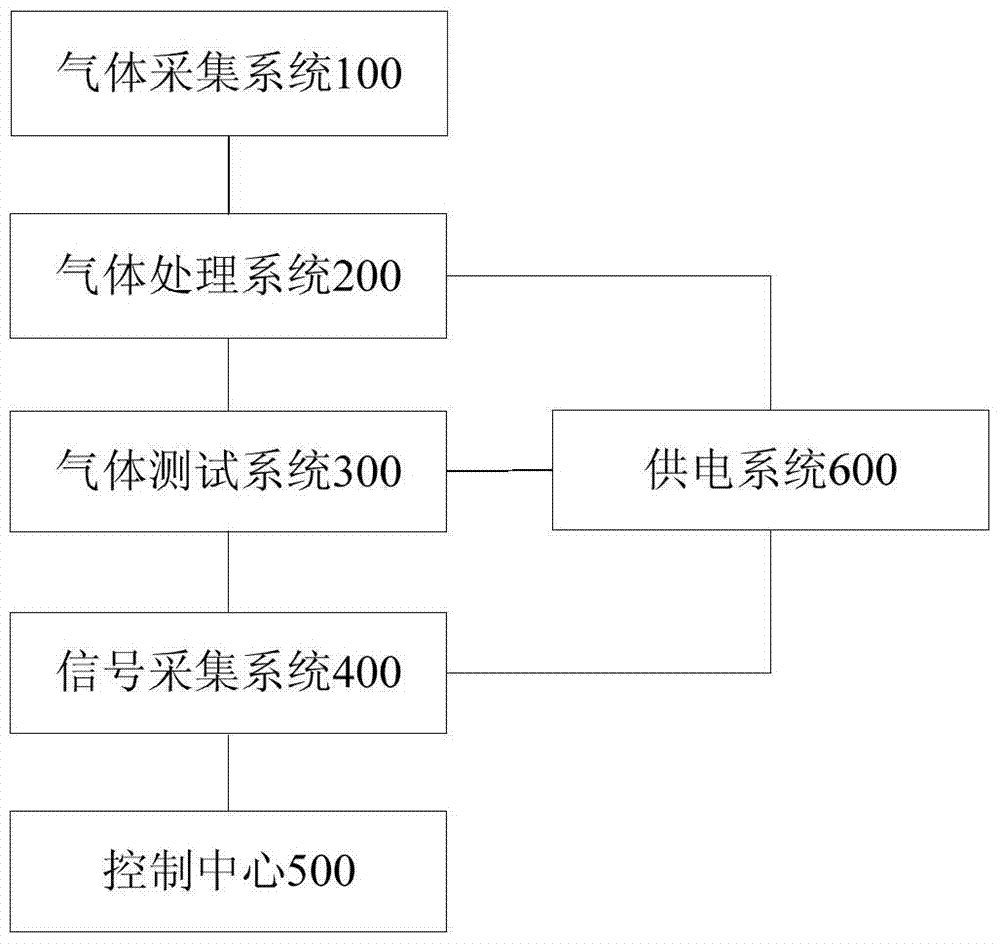

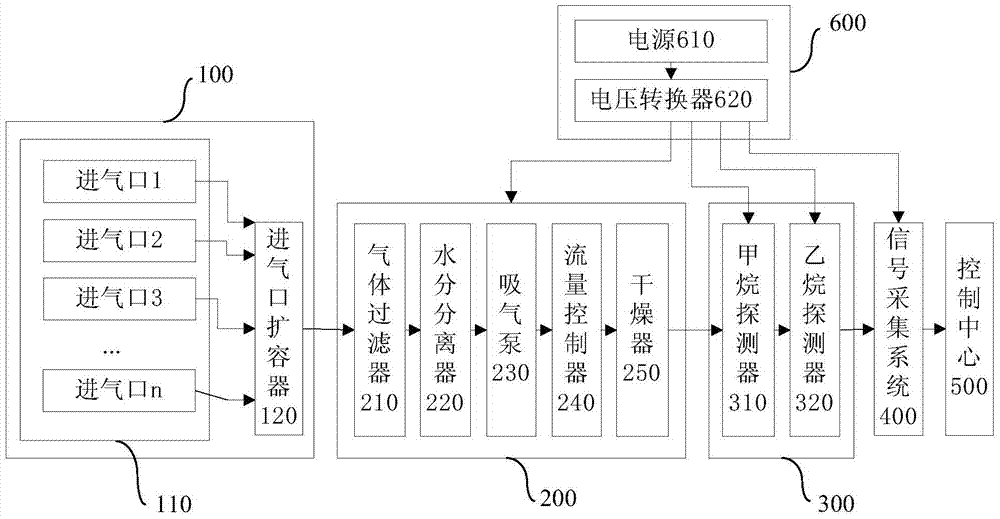

[0047] The multi-channel air sampling gas online monitoring system in the inspection well for monitoring gas leakage includes 5 gas inlets, a set of gas inlet expansion containers, gas filters, mechanical water and gas separators, suction pumps, and flow controllers , a dryer, a methane detector, an ethane detector, a street lamp power interface, a voltage converter, a signal collector, and a control center, wherein the gas inlet extends into the inspection well, and one end of the air inlet is connected to the suction funnel, The diameter of the funnel is less than 10cm, and the air inlet of the funnel is equipped with a plastic protective net with a mesh diameter of less than 2mm. The gas inlet and the air inlet expander are connected by a PE pipe with a diameter of 15mm. One end of the air inlet expander is connected to the mechanical gas filter with a PE pipe with a diameter of 15mm for gas, and the other end is connected to a 5-joint joint distributor to obtain 5 air inlet...

Embodiment 2

[0050] A multi-channel air sampling type gas online monitoring system for monitoring gas leakage, including 10 gas inlets, a set of gas inlet expanders, gas filters, mechanical water and gas separators, suction pumps, and flow control Devices, dryers, methane detectors, ethane detectors, street lamp power interfaces, voltage converters, signal collectors, and control centers, where one end of the gas inlet is connected to the suction funnel in the inspection well, and the diameter of the funnel is less than 10cm. The air inlet of the funnel is equipped with a plastic protective net, the mesh diameter is less than 2mm, and the gas inlet is connected to the expansion container of the air inlet with a PE pipe with a diameter of 15mm for gas. One end of the air inlet expander is connected to the mechanical gas filter with a PE pipe with a diameter of 15mm for gas, and the other end is connected to a joint distributor with 2 joints. Connect the connector distributor to get 10 inlet...

Embodiment 3

[0053] A multi-channel air sampling type gas online monitoring system in the inspection shaft for monitoring gas leakage, including 20 gas inlets, a set of gas inlet expansion containers, gas filters, electric water and gas separators, suction pumps, and flow control device, dryer, methane detector, ethane detector, street light power interface, voltage converter, signal collector, control center, wherein the gas inlet extends into the inspection well, and one end of the inlet is connected to the suction funnel, The diameter of the funnel is less than 10cm. The air inlet of the funnel is equipped with a plastic protective net. The mesh diameter is 1mm. Connect the PE pipe to the mechanical gas filter, and connect the other end to a 4-joint joint distributor, and then connect the 4-joint joint distributor to four 5-joint joint distributors to obtain 20 inlet joints and The air inlet is connected. The diameter of the mechanical gas filter is less than 10cm, and the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com