Parallel plane distance measurement device and measurement method

A measuring device and parallel plane technology, which is applied in the direction of mechanical gap measurement, photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of large measurement error, reading error, deformation, etc., and achieve good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

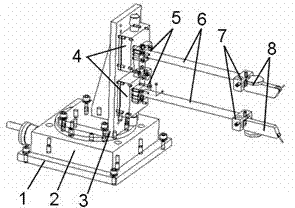

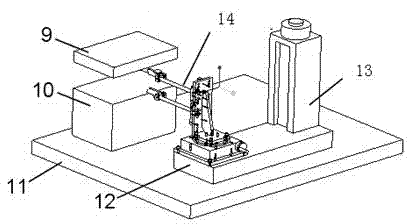

[0022] The first embodiment of the present invention is figure 1 and 2 As shown, it is a schematic diagram of the single-group two-way adjustment turntable type plane distance measuring device 14 of the present invention. The single-group two-way adjustable turntable plane measuring device 14 of the present invention includes a bottom plate 1 , a turntable 2 and a positioning bracket 3 . The rotating table 2 has an adjustment range of 360° and an axial load of 25KG; it can carry the positioning bracket 3 and all parts on it for rotational movement. The positioning bracket 3 includes two heavy-duty one-dimensional differential head adjustment translation stages 4 with a stroke of 12.5mm, two fixed bases 5, two support rods 6, two rod-end chucks 7 and two lever-type precision dial gauges 8 . Adjust the stroke of the translation platform 4 to 12.5mm and carry 10KG. The two 12.5mm stroke heavy-duty one-dimensional differential head adjustment translation stages 4 can be adjuste...

Embodiment 2

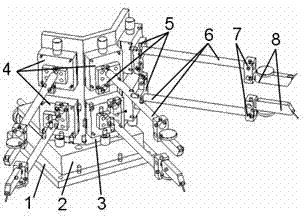

[0039] In another embodiment of the present invention, use three groups of two-way adjustment turntable type plane measuring devices 15, such as image 3 and 4 shown. The three-group two-way adjustable turntable-type plane measuring device 15 of the present invention includes a bottom plate 1 , a rotary table 2 and three sets of positioning brackets 3 . The rotating table 2 has an adjustment range of 360° and an axial load of 25KG; it can carry the positioning bracket 3 and all parts on it for rotational movement. Each set of positioning brackets 3 includes two 12.5mm stroke heavy-duty one-dimensional differential head adjustment translation stages 4, two fixed bases 5, two support rods 6, two rod-end chucks 7 and two lever-type precision dial gauges 8. The 12.5mm stroke heavy-duty one-dimensional differential head adjustment translation platform 4 has a stroke of 12.5mm and a load capacity of 10KG; two 12.5mm stroke heavy-duty one-dimensional differential head adjustment tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com