Bend type shielded mcu bus plug

A bus plug and curved technology, applied in the field of curved shielded MCU bus plugs, can solve the problems of not meeting the use requirements of new energy vehicles on curved shielded plugs, poor shielding effectiveness of shielding processing methods, and inability to meet the use requirements, etc. Achieve the effect of benefiting cost control and mass production, benefiting cost control and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

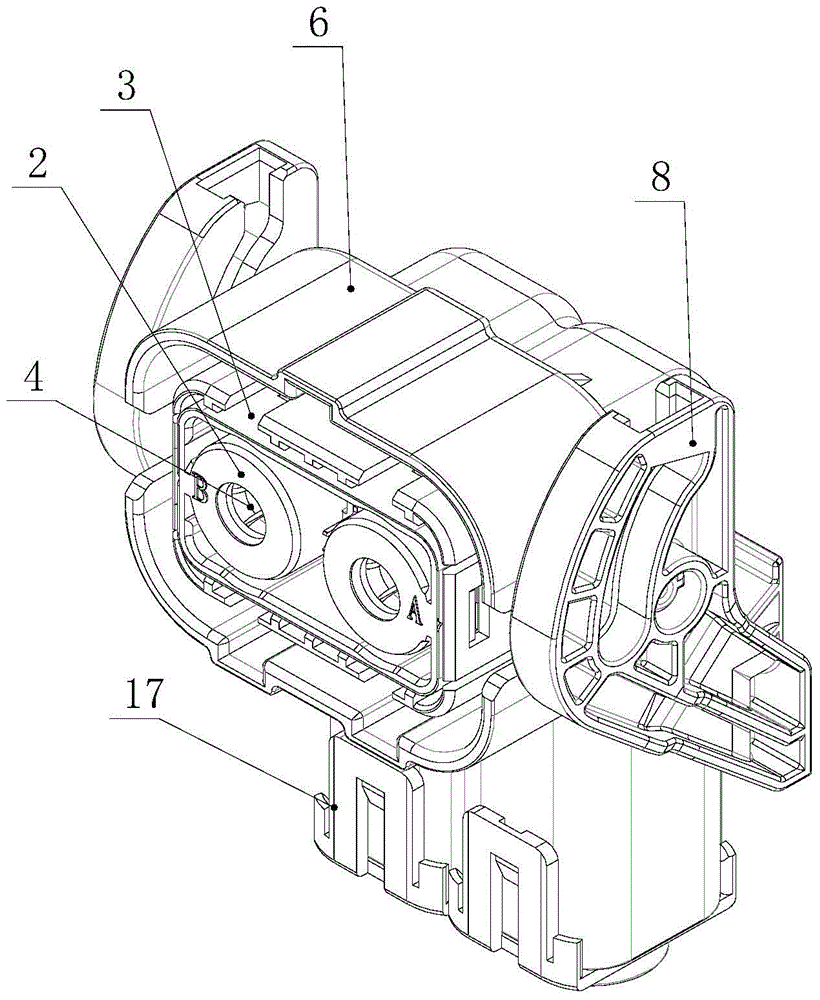

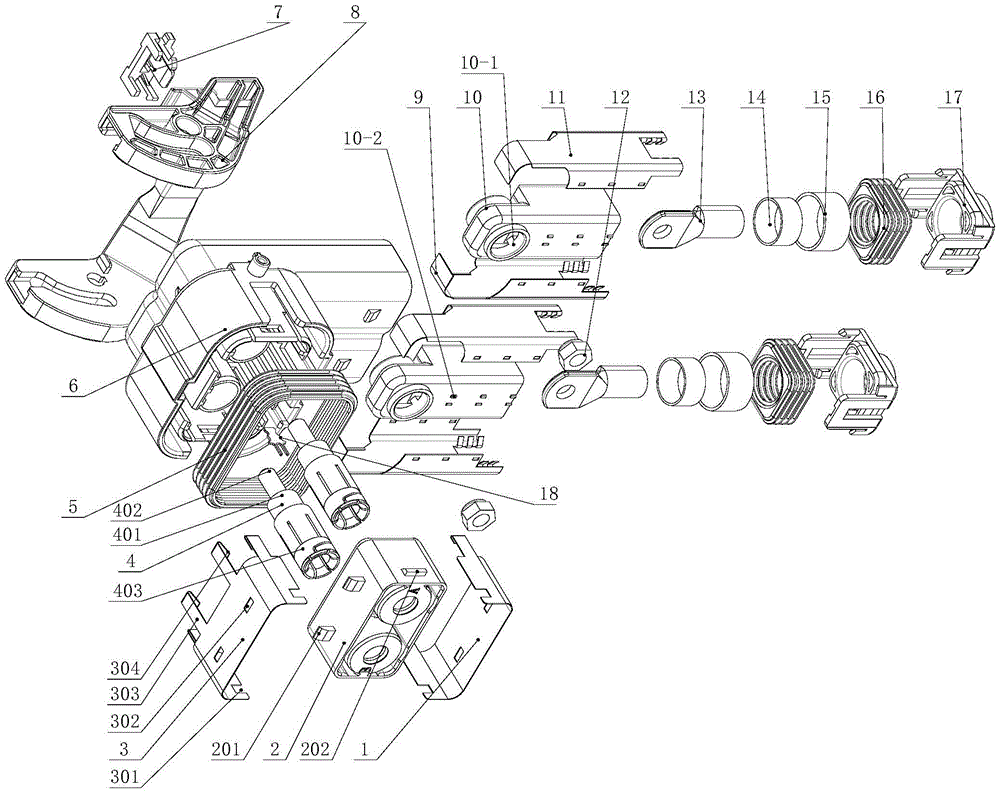

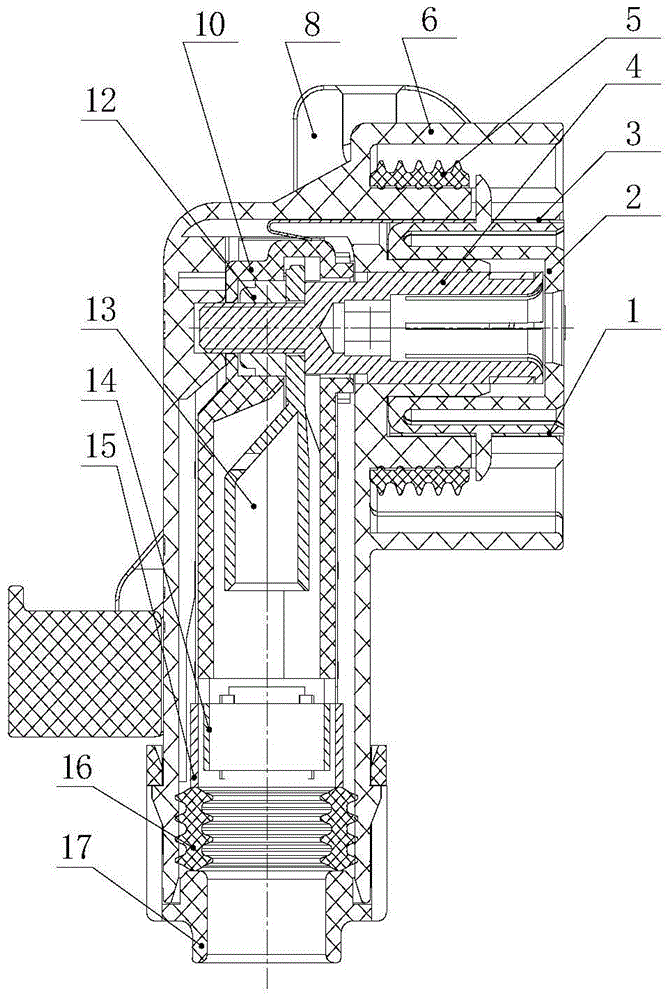

[0045] like Figure 1-3 As shown, a curved shielded MCU bus plug consists of a lower shield 1, a jack mounting plate 2, an upper shield 3, a jack assembly 4, a sealing ring 5, a plug shell 6, a lock block 7, a handle 8, The left shield 9, the sheath 10, the right shield 11, the self-locking nut 12, the connection terminal 13, the shield pad cover 14, the shield pressure sleeve 15, the sealing wire body 16, and the tail cap 17 are formed.

[0046] like Figure 4 and Figure 5 As shown, the plug housing 6 is generally "L"-shaped, and is divided into an insertion part 601 and a wiring part 602. The periphery of the insertion part 601 is provided with a plurality of fool-proof keyways 603, and the two sides of the insertion part 601 There are two hollow rotating shafts 608 arranged symmetrically at the root. On the inner ring of the mating part 601, there is a sealing ring installation platform 605. The upper and lower sides of the installation platform 605 are equipped with mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com