Leaktight box for alkaline batteries

An elastic seal and alkaline technology, applied in the field of battery container manufacturing, can solve the problems of high cost and material incompatibility, and achieve the effect of reducing cost and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

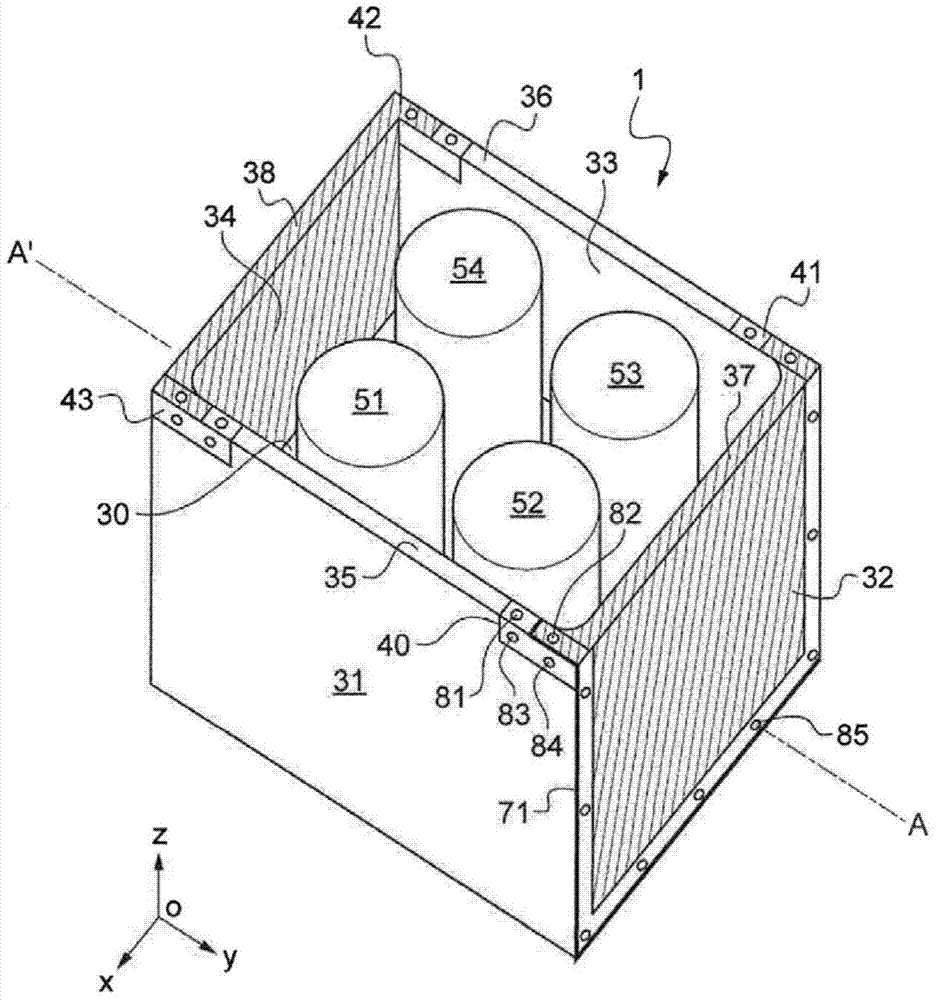

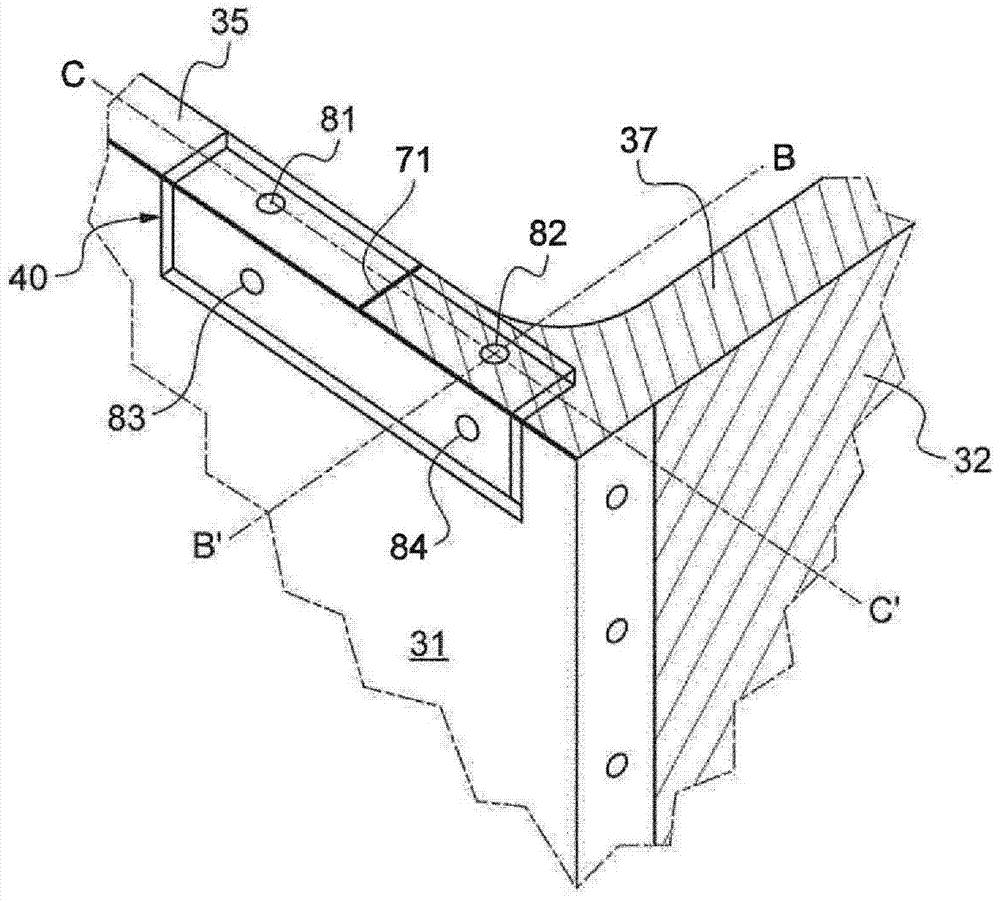

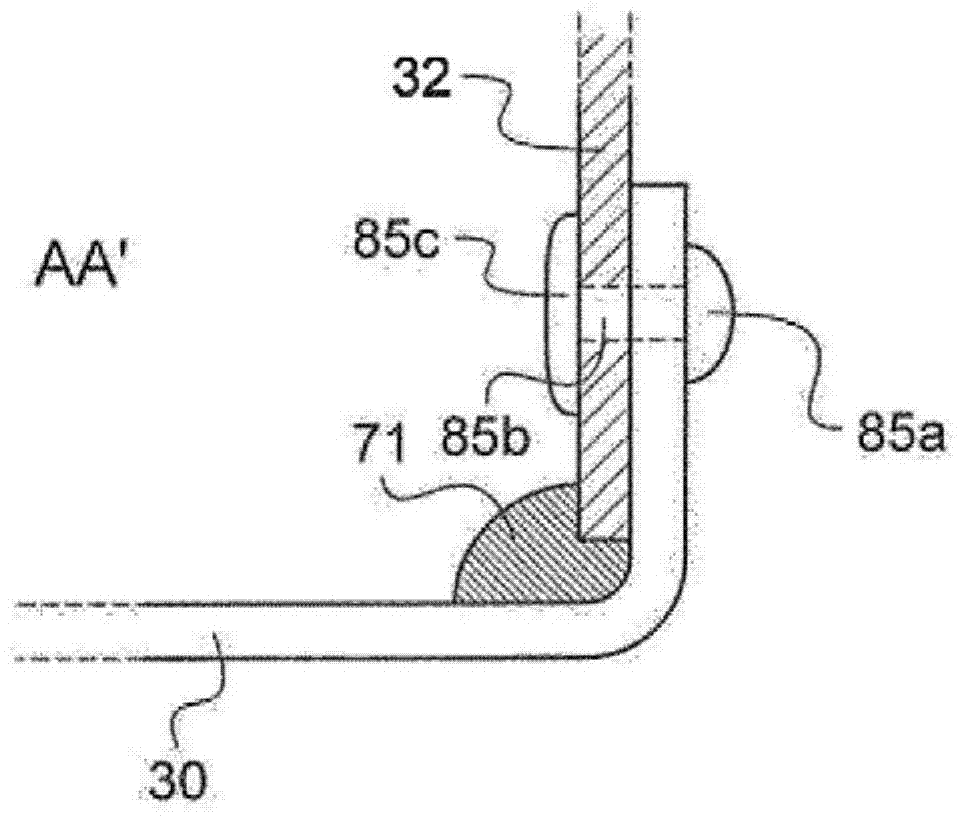

[0061] figure 1 A perspective view of a battery tray 1 according to the invention is shown. The tray is in the shape of a parallelepiped. The parallelepiped comprises a metal plate 30 forming a bottom on which secondary cells (51, 52, 53, 54). The upper side of the battery tray, ie, the side opposite to the bottom, is open to allow the introduction of single cells into the interior of the battery tray. The upper left side plate and the upper right side plate have flange edges (35, 36) corresponding to the direction of the upper edge portions of these plates pointing towards the battery in a direction generally perpendicular to the direction of the plates. The inside of the tray and the folded part. The upper front end and the upper rear end of the left-hand side plate 31 and the right-hand side plate 33 each have a portion called a recess where the flange edge is missing, to which the front plate 32 and the rear plate 34 of the battery tray fitting are fitted. in the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com