High-efficiency low-resistance air filter material prepared from special-shaped melt-blown fiber

An air filter material and melt-blown fiber technology, applied in the field of industrial textiles, can solve the problems of failing to meet PM2.5 fine filtration requirements, unable to realize industrial production, general efficiency and resistance, etc., to achieve low production cost, High feasibility, the effect of little change in rate resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

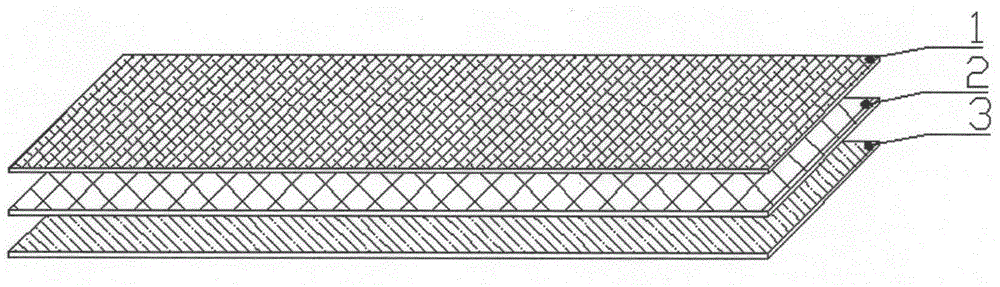

[0021] A high-efficiency and low-resistance air filter material prepared from special-shaped melt-blown fibers. The preparation method is: the surface density is 60g / m 2 The cross-section is triangular PET chemical fiber with 80g / m 2 The cross-section of the PET chemical fiber is triangular to prepare a fluffy fiber web by carding, which is used as a coarse filter layer and a fine filter layer in turn. Prepare the middle layer with an area density of 20g / m 2 PP triangular meltblown fibers. The coarse filter part 1, the support part 2, and the fine filter part 3 are arranged in order from top to bottom, and the acupuncture depth is 7 mm, and the acupuncture density is 432 needles / cm 2 Acupuncture reinforcement is carried out under certain conditions, and the various parts of the filter material are connected to form a high-efficiency and low-resistance air filter material. Its structure is as follows: figure 1 shown.

[0022] Use (LZC-K 1 Filter material comprehensive perf...

Embodiment 2

[0024] A high-efficiency and low-resistance air filter material prepared from special-shaped melt-blown fibers. The preparation method is: the surface density is 50g / m 2 The cross-section is triangular and circular mixed with PET chemical fiber and 75g / m 2 The cross-section is triangular and circular mixed with PET chemical fibers to prepare fluffy webs by carding, which are used as coarse filter layer and fine filter layer in turn. Prepare the middle layer with an area density of 30g / m 2 PP dumbbell-shaped melt-blown fibers. The coarse filter part 1, the support part 2, and the fine filter part 3 are arranged in order from top to bottom, and the acupuncture depth is 6 mm, and the acupuncture density is 450 needles / cm 2 Acupuncture reinforcement is carried out under certain conditions, and the various parts of the filter material are connected to form a high-efficiency and low-resistance air filter material. Its structure is as follows: figure 1 shown.

[0025] Use (LZC-K ...

Embodiment 3

[0027] A high-efficiency and low-resistance air filter material prepared from special-shaped melt-blown fibers. The preparation method is: the surface density is 65g / m 2 The cross-section is triangular PET chemical fiber with 80g / m 2 The cross-section is triangular and circular mixed with PET chemical fibers to prepare fluffy webs by carding, which are used as coarse filter layer and fine filter layer in turn. Prepare the middle layer with an area density of 25g / m 2 PP trilobal melt blown fiber. The coarse filter part 1, the support part 2, and the fine filter part 3 are arranged in order from top to bottom, and the acupuncture depth is 5 mm, and the needle density is 420 needles / cm 2 Acupuncture reinforcement is carried out under certain conditions, and the various parts of the filter material are connected to form a high-efficiency and low-resistance air filter material. Its structure is as follows: figure 1 shown.

[0028] Use (LZC-K 1 Filter material comprehensive per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com