Patents

Literature

33results about How to "With filtering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

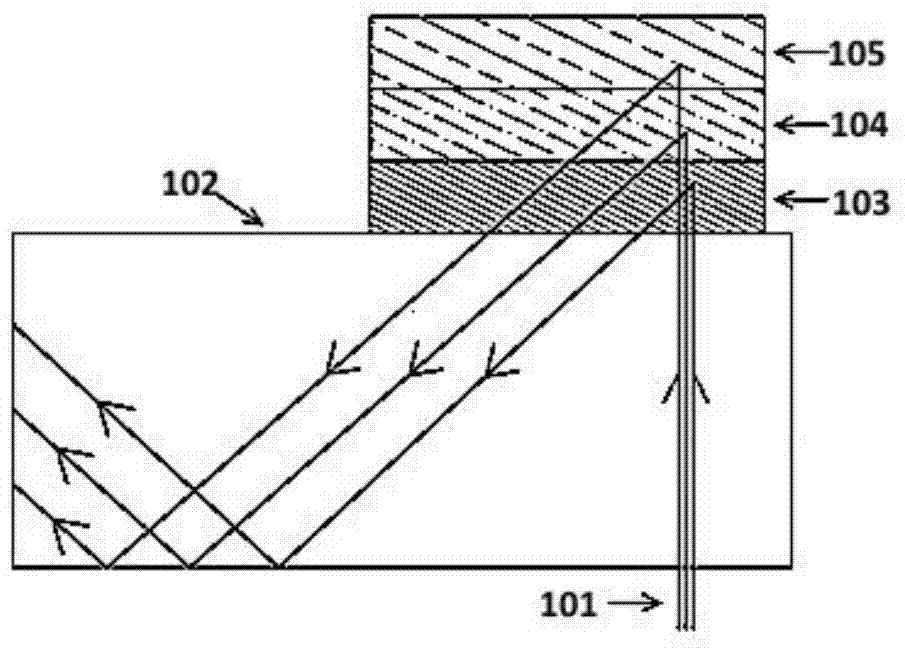

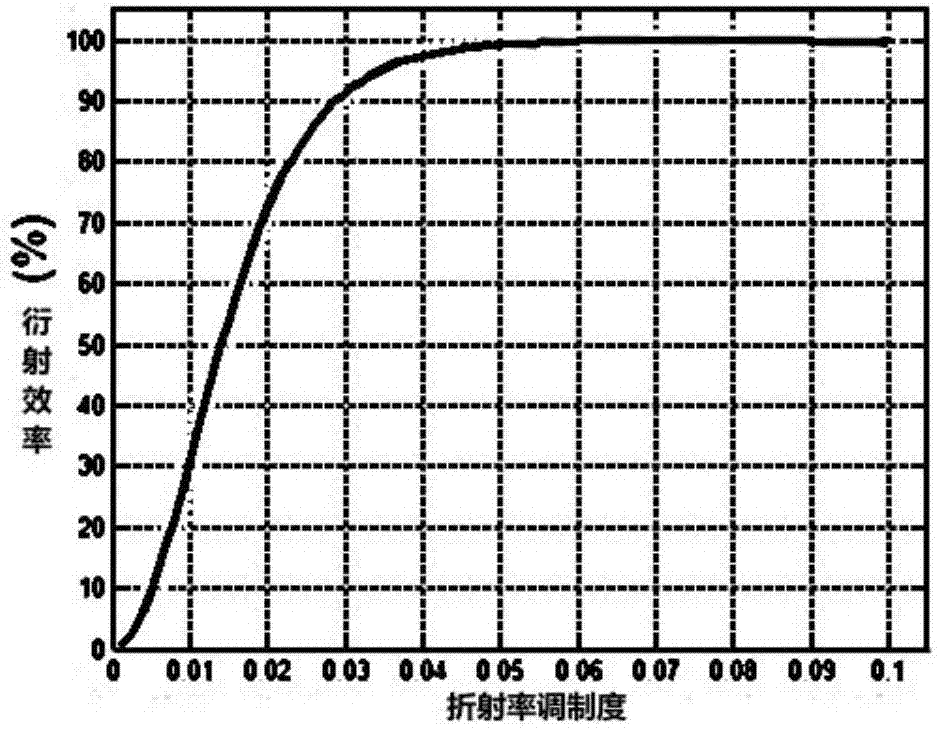

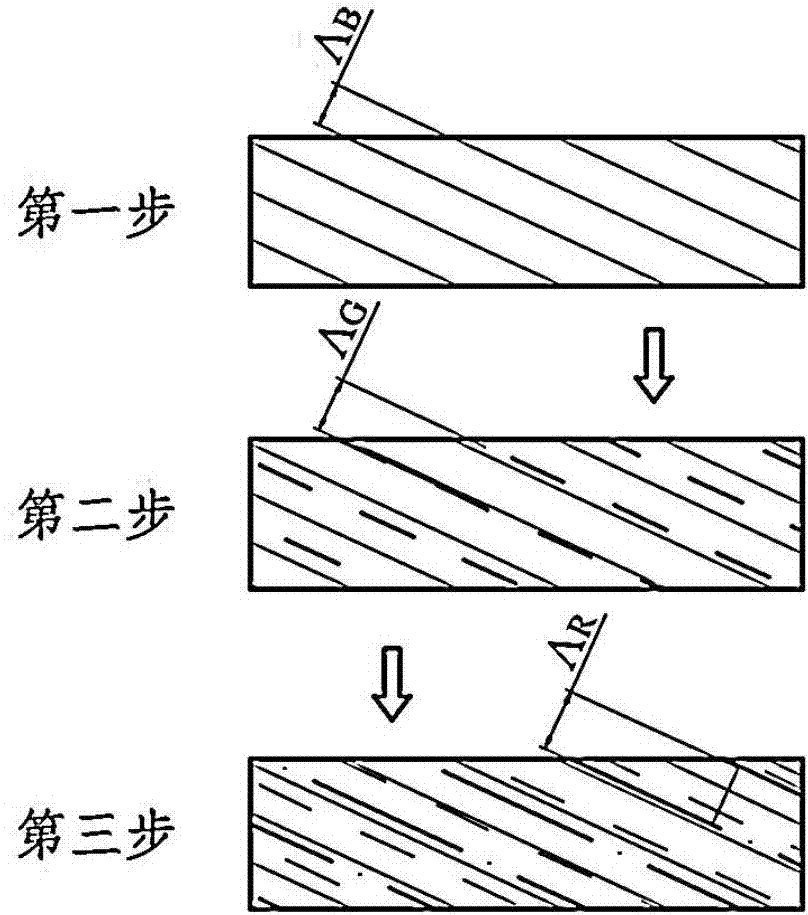

Multiplexed volume holographic grating

The invention discloses a multiplexed volume holographic grating. The multiplexed volume holographic grating respectively records red, green and blue three holograms on the same dielectric layer by exposing for three times; volume holographic gratings formed by exposure of different wavelengths are the same in inclination angle and are different in period; by controlling exposure time, refractive index modulation depths corresponding to red, green and blue light after exposure accords with the relation that delta n red light is greater than delta n green light, and delta n green light is greater than delta n blue light, and peak diffraction efficiencies corresponding to the red, green and blue light after exposure are similar. The multiplexed volume holographic grating can effectively balance irradiating energy of red, green and blue light waves and avoid color offset.

Owner:SOUTHEAST UNIV

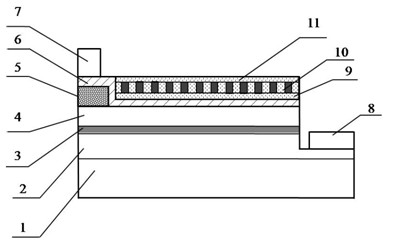

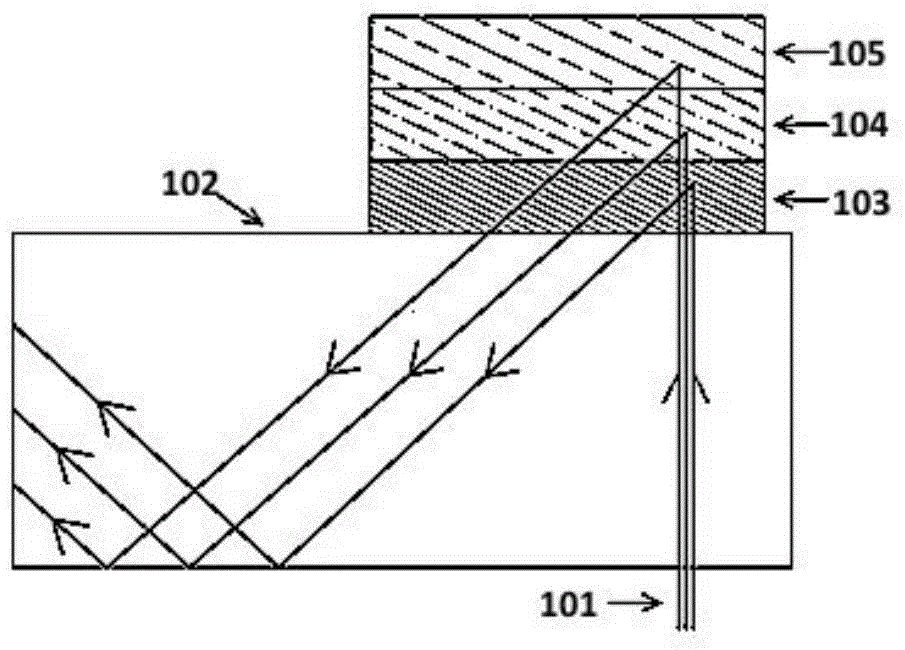

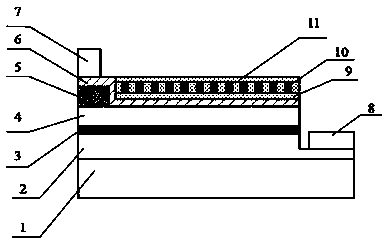

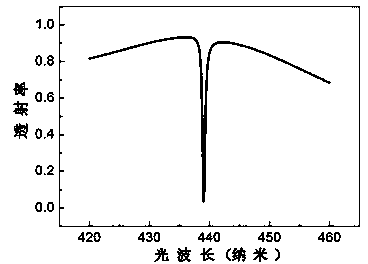

LED outputting narrow-band notch filtering light and preparation method thereof

ActiveCN102544265AWith filtering effectAdd resonance filter effectDiffraction gratingsSemiconductor devicesGratingResonance

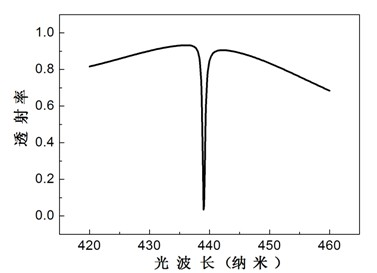

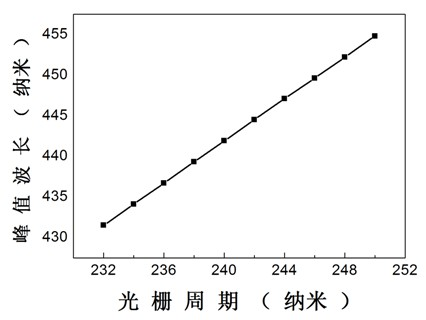

The invention discloses an LED outputting narrow-band notch filtering light, and a preparation method thereof. According to the invention, a multi-layer waveguide structural layer is composited on the light-emitting surface of an LED chip and comprises a medium depletion layer, a composite grating layer and a medium protective layer; the composite grating layer is a metal / medium grating film layer which is formed by metal strips and medium strips at intervals; the medium depletion layer is positioned below the composite grating layer and is in direct contact with the light-emitting surface of the LED chip; the medium protective layer is above the composite grating layer and is in direct contact with the ambient environment or transparency electrode; and the thickness of each layer of the multi-layer waveguide structure layer, the grating duty cycle and the period parameter are designed to meet the condition of the resonance of the light waveguide mold transmission. According to the invention, a sub-wavelength metal / medium composite grating structure is directly integrated on the surface of the LED chip, and the LED per se has filtering effect; and compared with a traditional passive filter, the LED is a highly integrated active filtering light-emitting device.

Owner:苏州东辉光学有限公司

Hf-surgery device and method for an hf-surgery device

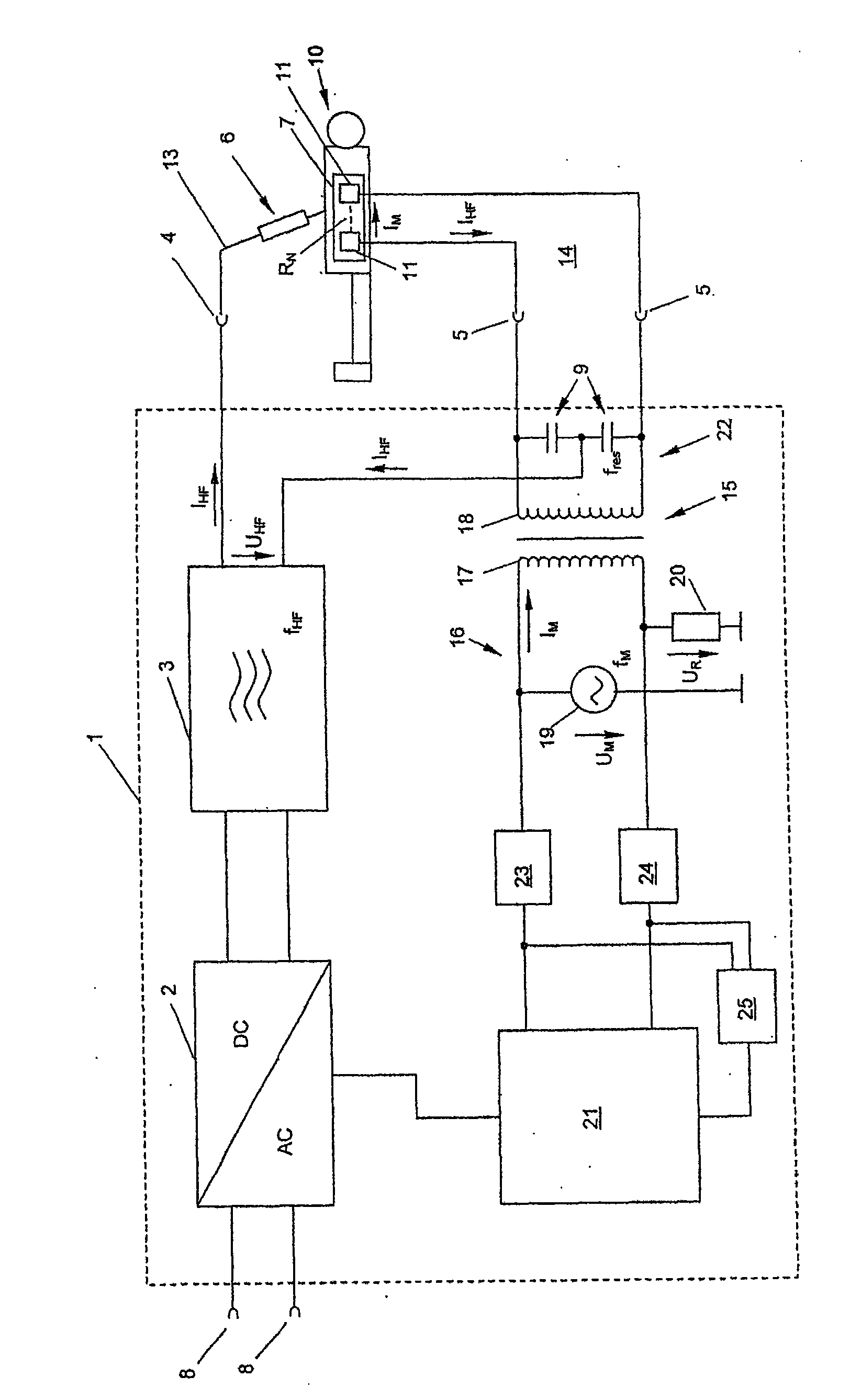

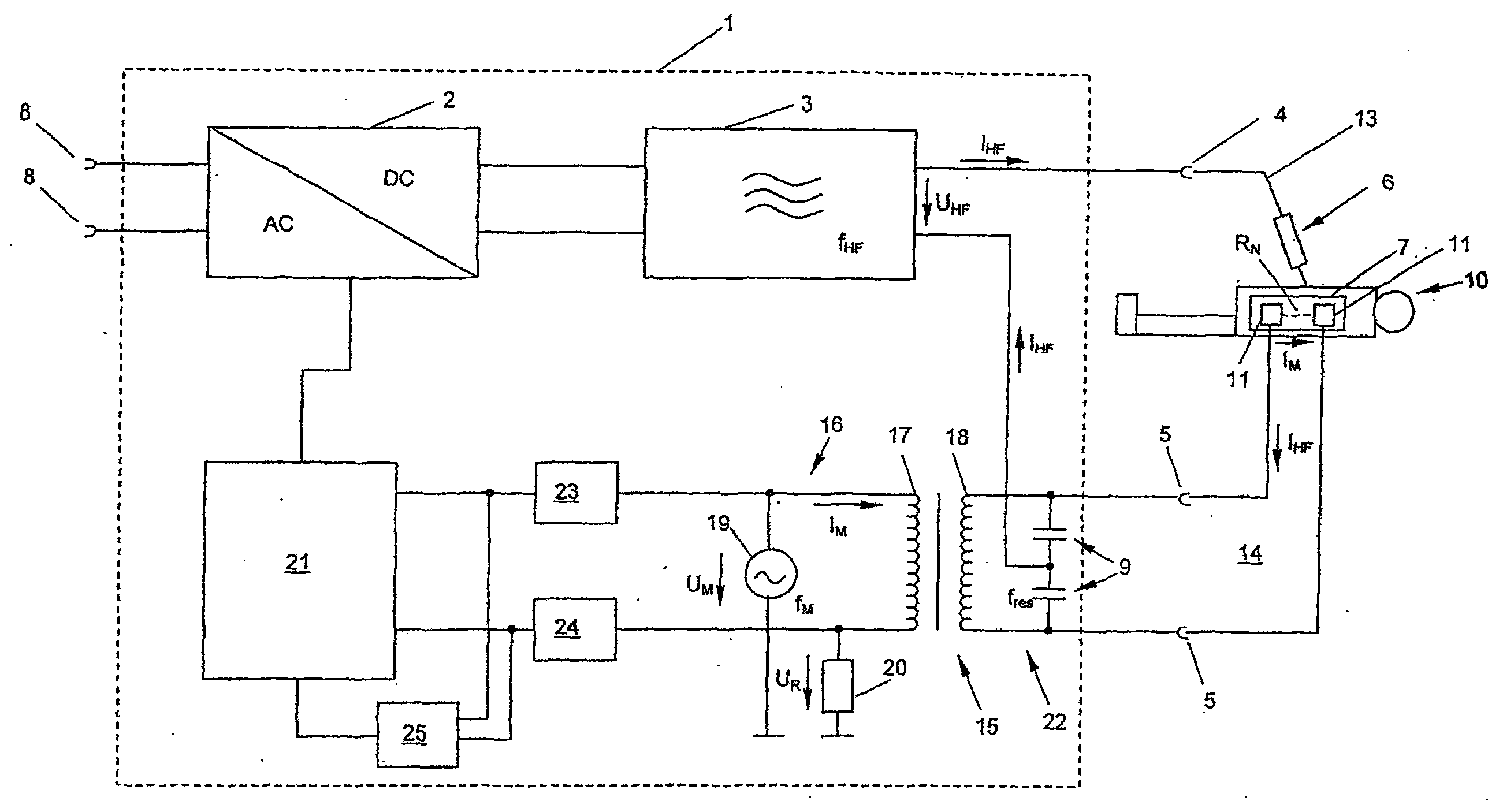

ActiveCN102215768AAccurate contactReduce the impact of interferenceSurgical needlesSurgical instruments for heatingPower flowSkin contact

The invention concerns an HF-surgery device for cutting and / or coagulating biological tissue and a method for same, which in operation monitors the patient skin contact of a connected neutral electrode having at least two separate contact surfaces. The HF-surgery device includes at least one parallel resonant circuit arranged in a patient circuit, at least one measurement energy source arranged in a measurement circuit galvanically separated from the patient circuit for producing a measurement voltage / current acting between the contact surfaces of the neutral electrode, and at least one measuring and computing unit which in operation determines by means of the measurement voltage / current a tissue impedance which is representative of the patient skin contact and which acts between the contact surfaces. An HF-current flows in the patient circuit which is closed in the cutting or coagulation operation and the measurement voltage which is independent of the HF-current can be produced in the measurement circuit. To provide an improved HF-surgery device it is provided according to the invention that the frequency of the measurement voltage source is substantially equal to a resonance frequency of the parallel resonant circuit.

Owner:OLYMPUS WINTER & IBE GMBH

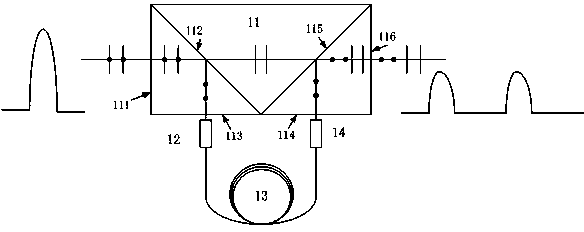

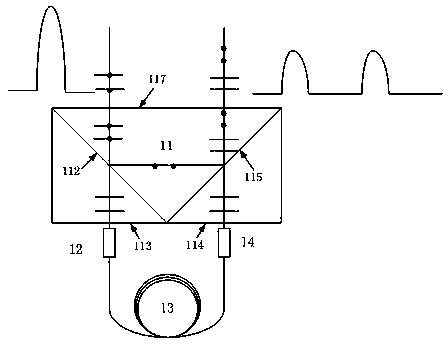

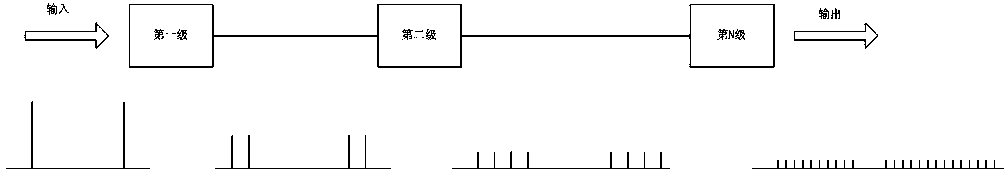

Optical fiber type pulse widening and compressing method based on polarization beam splitting

InactiveCN104051944AReduce weightSimple structureLaser detailsOptical elementsPulse beamBeam splitting

The invention discloses an optical fiber type pulse widening and compressing method based on polarization beam splitting. According to the method, a laser pulse beam is divided into P light and S light when passing through the beam splitting face of a polarization beam splitter, the two beams of light are transmitted along different paths, the P light or the S light continues to be transmitted in the polarization beam splitter, the S light or the P light is reflected to enter an optical fiber to be transmitted, the two beams of light generate time delay of a certain degree due to difference of the transmission paths, the time delay is completely determined by length of the optical fiber, two sub-pulses at a fixed interval are formed after the P light and the S light are combined again when passing through the beam splitting face of the polarization beam splitter, the amplitude of the sub-pulses is generally one half that of the parent pulses, and the optical fiber type pulse widening and compressing method based on polarization splitting greatly reduces the peak power of the pulse. The widening amount is easily and accurately controlled, the structure is simple, assembly is easy and stability is better.

Owner:SHANGHAI LANGYAN OPTOELECTRONICS TECH

Method for modeling control object in cooling process of central air conditioner

InactiveCN102866632ALow experimental requirementsEliminate negative effectsAdaptive controlInterference resistanceModel control

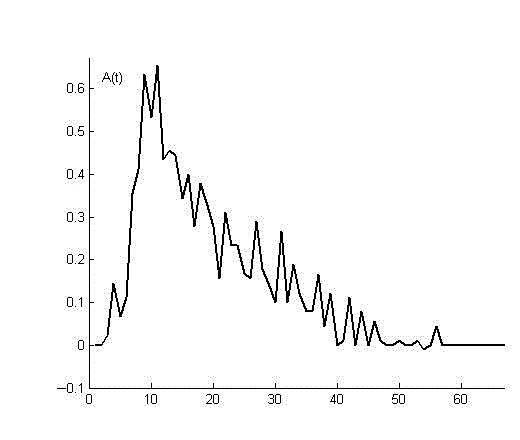

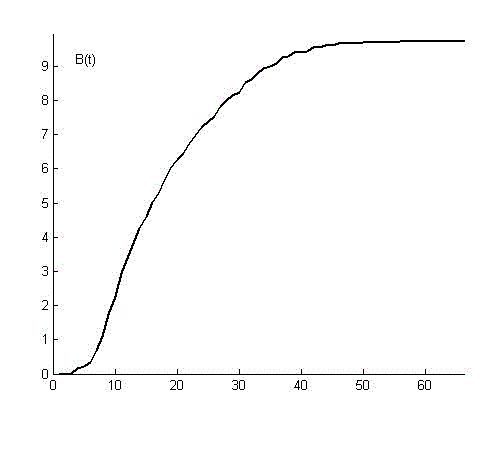

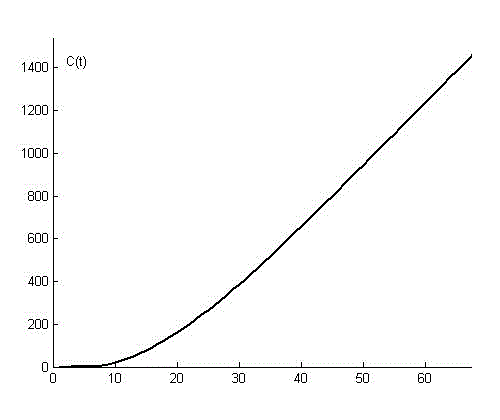

The invention provides a method for modeling a control object in a cooling process of a central air conditioner, relating to the field of cooling control technologies. The method has the advantages that the modeling accuracy and interference resistance are improved. According to the method, a pulse response curve of the control object is obtained firstly in a measurement manner, a step response curve and a ramp response curve are then obtained, a difference equation is written according to a measurement sample, the proportionality constant, time constant and lag time constant of the control object are obtained by using a least square method, a typical second-order plus lag object model is combined so as to obtain a pulse transfer function, and a difference equation of a control object model is further obtained. According to the method provided by the invention, the requirements for experimental conditions and site environments are low, the method has a filter action, the interference resistance is stronger, the modeling accuracy and reliability are high, and the modeling accuracy can be increased to be less than 3% from 7% compared with that of the conventional ascending curve method.

Owner:SHANGHAI DAXI ENERGY TECH

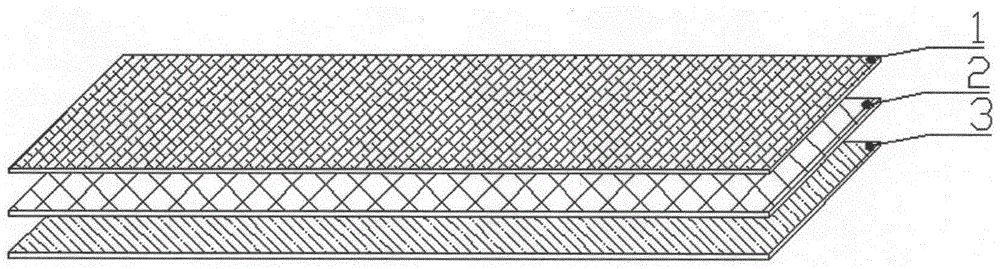

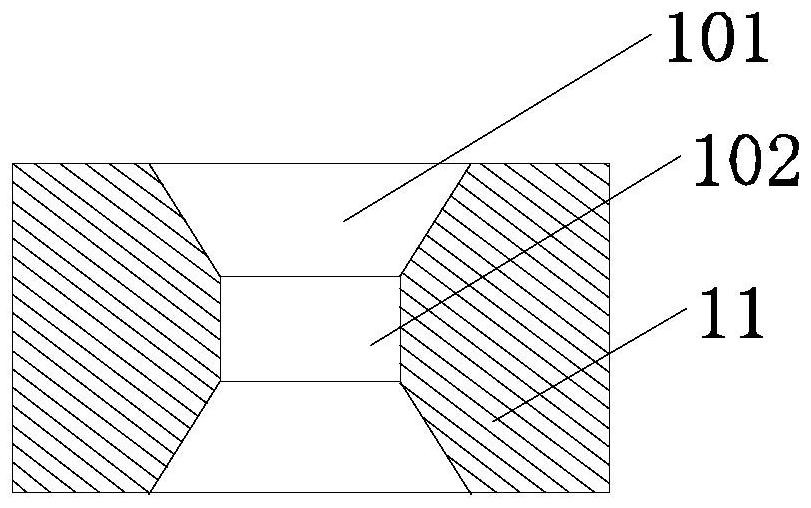

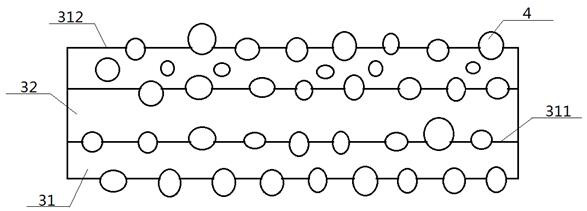

Melt-blowing filtering material with three-dimensional twisted fiber structure and preparation method of melt-blowing filtering material

InactiveCN107737491ALarge specific surface areaImprove mechanical propertiesMembrane filtersFiltration separationVolumetric Mass DensityMelt blowing

The invention relates to a melt-blowing filtering material with a three-dimensional twisted fiber structure and a preparation method of the melt-blowing filtering material. The melt-blowing filteringmaterial with the three-dimensional twisted fiber structure comprises a coarse filtering part, a supporting part and a fine filtering part which are sequentially connected by needling from top to bottom. The preparation method of the melt-blowing filtering material comprises the following steps: firstly, preparing the coarse filtering part; secondly, preparing the supporting part; thirdly, preparing the fine filtering part; fourthly, sequentially arranging the coarse filtering part, the supporting part and the fine filtering part from top to bottom to form a filtering material with a sandwichstructure; fifthly, needling the filtering material with the sandwich structure at the needling depth of 5 to 7mm and the needling density of 390 to 480 needles / cm<2>; connecting all parts of the filtering material to obtain the melt-blowing filtering material with the three-dimensional twisted fiber structure. The melt-blowing filtering material disclosed by the invention has the advantages thatspecial surface area of the inner part of a fiber network is increased, and mechanical properties are excellent; the preparation method has the advantages of simplicity, convenience, low cost, high production efficiency, better filtering performance and small reluctivity change.

Owner:无锡风正科技有限公司

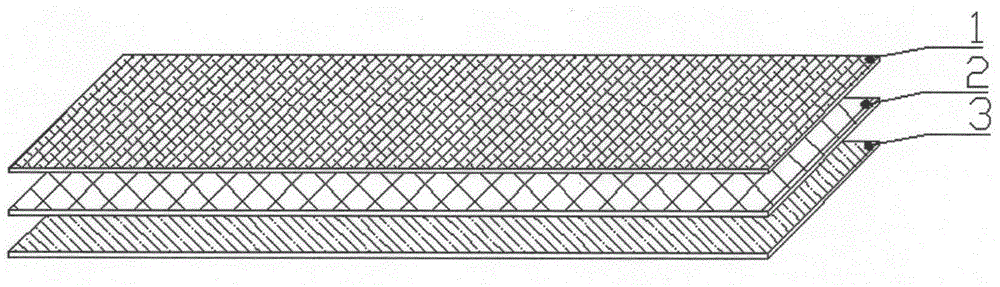

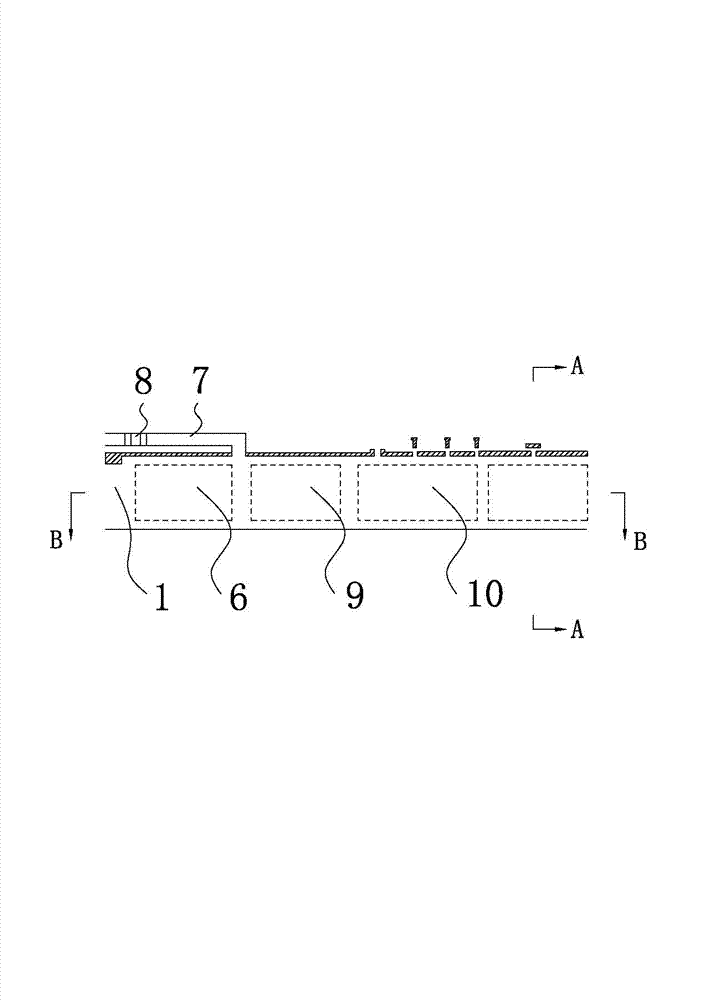

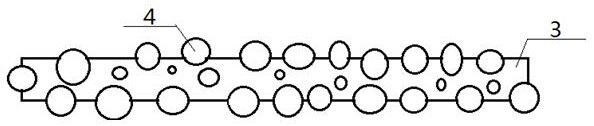

High-efficiency low-resistance air filter material prepared from special-shaped melt-blown fiber

InactiveCN104785019AEasy to operateLow costLayered productsFiltration separationFiberPolymer science

The invention discloses a high-efficiency low-resistance air filter material prepared form special-shaped melt-blown fiber and a preparation method of the high-efficiency low-resistance air filter material. The high-efficiency low-resistance air filter material is characterized in that a coarse filtration part, a supporting part and a fine filtration part are sequentially arranged from top to bottom to form a filter material adopting a sandwich structure; needling is performed under the conditions that the needling depth ranges from 5 mm to 7 mm and the needling density ranges from 390 needles per cm<2> to 480 needles per cm<2>, and all parts of the filter material are connected to form the high-efficiency low-resistance air filter material; the coarse filtration part and the fine filtration part are made from chemical fiber and combed into net-shaped structure, and the supporting part is made from the special-shaped melt-blown fiber. The high-efficiency low-resistance air filter material has high filter efficiency, the filter resistance is lower, the manufacturing cost is low, and the process is simple and environment-friendly; the special-shaped melt-blown fiber is used for preparing the filter material for the first time, and a great breakthrough is made in the field of filter materials.

Owner:DONGHUA UNIV

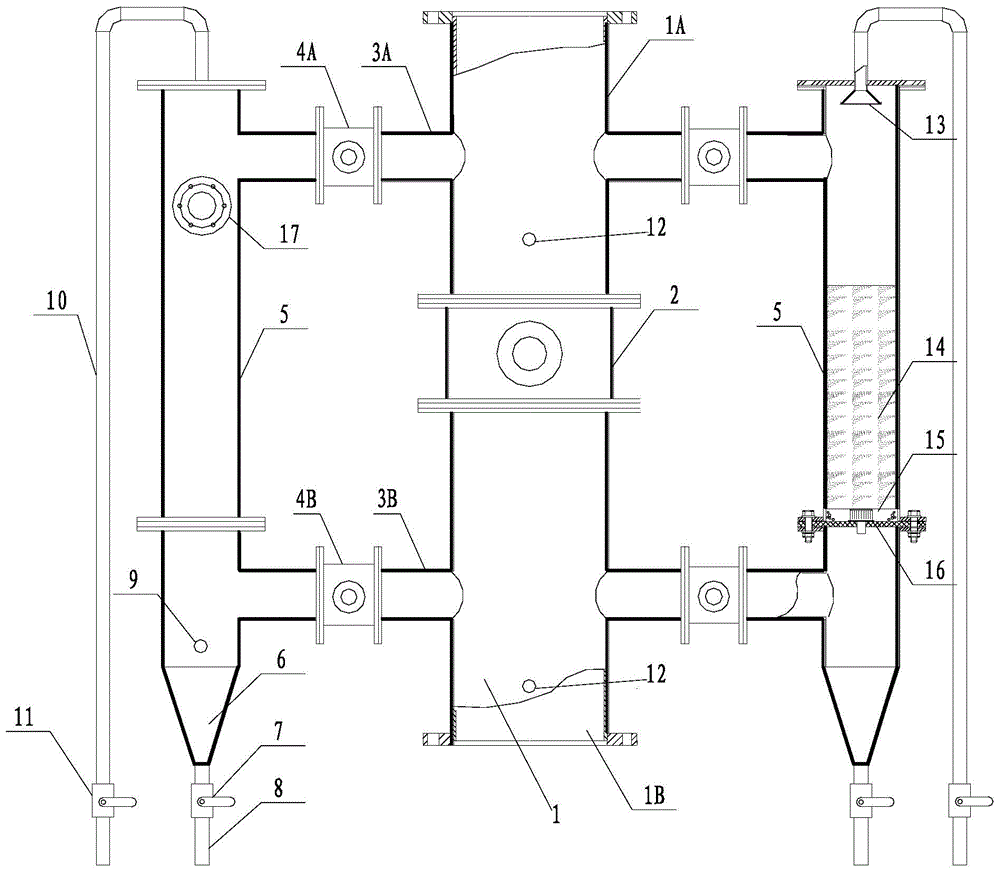

Livestock manure digestion facility

InactiveCN105668971AReliable deliveryReduce volumeSludge treatment by de-watering/drying/thickeningWaste water treatment from animal husbandryLivestock manureThree stage

Aiming at the problem of "screening first and pressing later" manure treatment process and equipment, it proposes septic grade change, manure sludge dehydration, manure fermentation, and manure water filtration; a suitable, reliable and economical anaerobic digestion facility for manure is disclosed. The facility has a septic tank composed of a septic tank and a septic valve, and the operation of the septic valve enters the fourth-stage or third-stage anaerobic digestion mode of manure; there is a manure ditch or a manure pipe, and the potential energy is used to send manure; there is also a filter The cylinder and pump / pipe can sink into the septic chamber to pump water, dehydrate the sludge into manure, and then dig out the manure and transport it out for accumulation and fermentation; the filter cartridge can also be covered with a filter cloth bag, and the filter cartridge can be sunk into the manure chamber , pump out clean water and send to rinse.

Owner:戴增池

A building dense point cloud rapid reconstruction method based on PMVS

The invention discloses a building dense point cloud rapid reconstruction method based on PMVS. In an application scene of 3D reconstruction of buildings, the method uses the quasi-dense point cloud to replace the self-built sparse point cloud of a PMVS algorithm as a diffusion seed point. The main flow of the method of the invention comprises the following steps: first, an initial spatial triangular mesh model of the building is constructed, spatial interpolation diffusion, patch optimization and filtering, triangular mesh information updating and other operations are carried out to obtain accurate quasi-dense point cloud, and the quasi-dense point cloud is used to replace the self-built sparse point cloud of the PMVS algorithm as a diffusion seed point, and thus acceleration of the reconstruction process of the PMVS algorithm is realized. The method can effectively improve the operation efficiency of the PMVS algorithm. The method plays a certain filtering effect on the point cloud noise brought by natural landscapes and other non-building main body point cloud noise.

Owner:SOUTHEAST UNIV

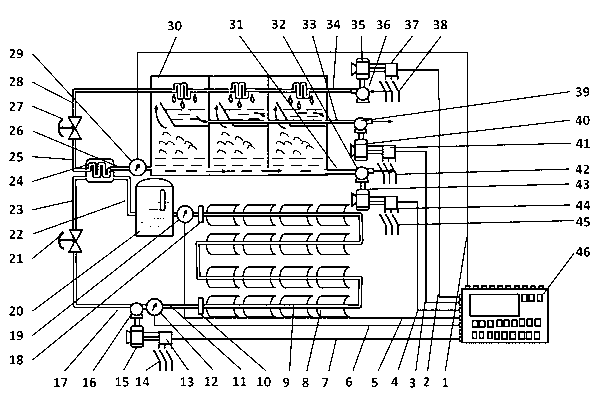

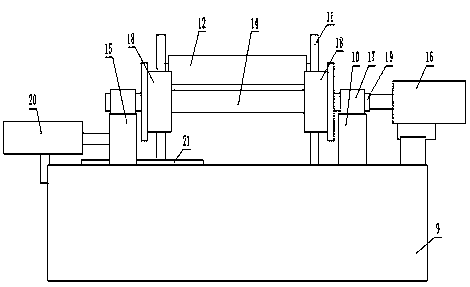

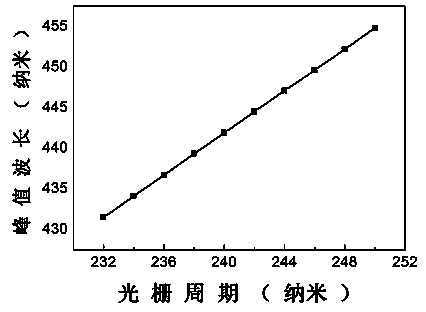

Light-condensing and heat-collecting multistage flash evaporation process device based on feedback control

ActiveCN102701305AIncrease the concentration ratioImprove utilization efficiencyGeneral water supply conservationSeawater treatmentThermal energyConjugated heat transfer

The invention discloses a light-condensing and heat-collecting multistage flash evaporation process device based on feedback control. How to overcome the characteristic that a solar heat source is instable is not considered in the prior art. The light-condensing and heat-collecting multistage flash evaporation process device comprises a solar heat-collecting system, a heat transfer system, a seawater desalting system, a feedback control system and a heat exchanger; the heat transfer system constructs a closed heat transfer working medium circulating loop; the closed heat transfer working medium circulating loop allows a heat conducting working medium to repeatedly circulate; and a seawater desalting loop formed by the seawater desalting system is in an open structure and allows the seawater desalting system to continuously generate fresh water. Meanwhile, a feedback control loop is applied to the light-condensing and heat-collecting multistage flash evaporation process device disclosed by the invention; a flow temperature meter is used for measuring fluid and temperature signals in several pipelines and feeding back the signals to an industrial controller; and according to the feedback signals, the industrial controller generates a control command for adjusting the rotating speeds of each motor and each centrifugal pump. According to the light-condensing and heat-collecting multistage flash evaporation process device disclosed by the invention, adverse influence generated by solar fluctuation is overcome; and meanwhile, the utilization efficiency of heat energy is increased and energy saving and environment friendliness are realized.

Owner:HANGZHOU DIANZI UNIV

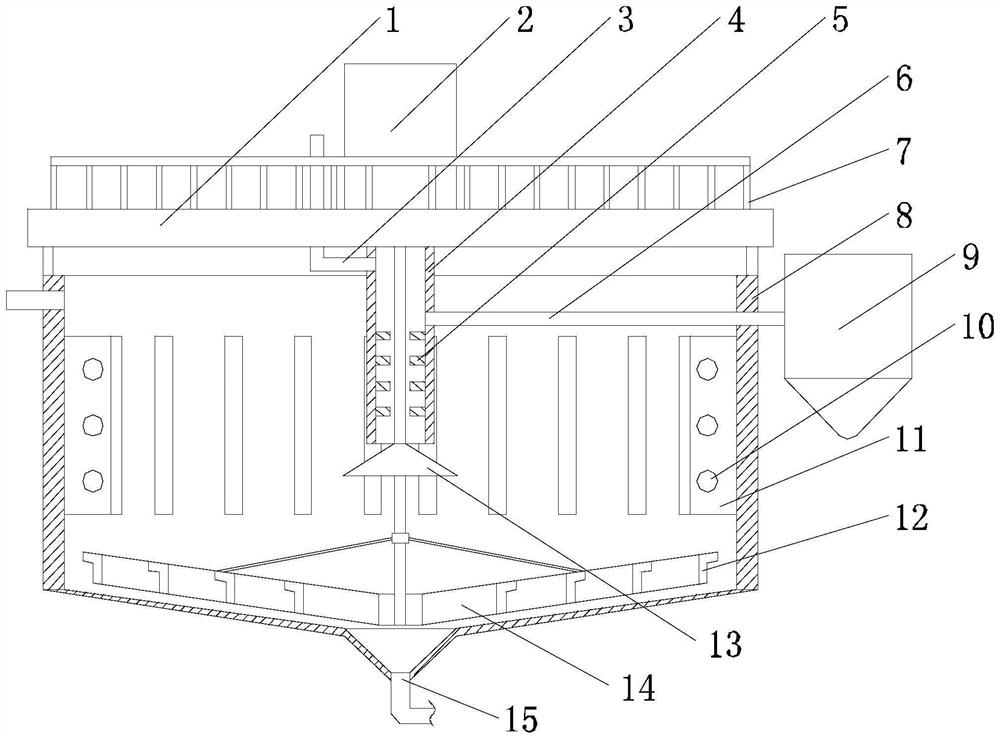

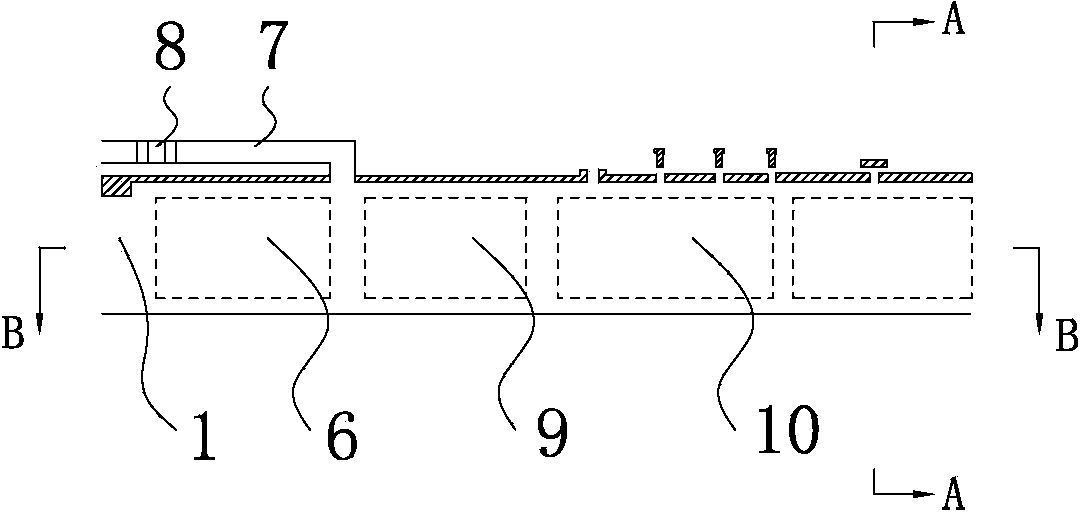

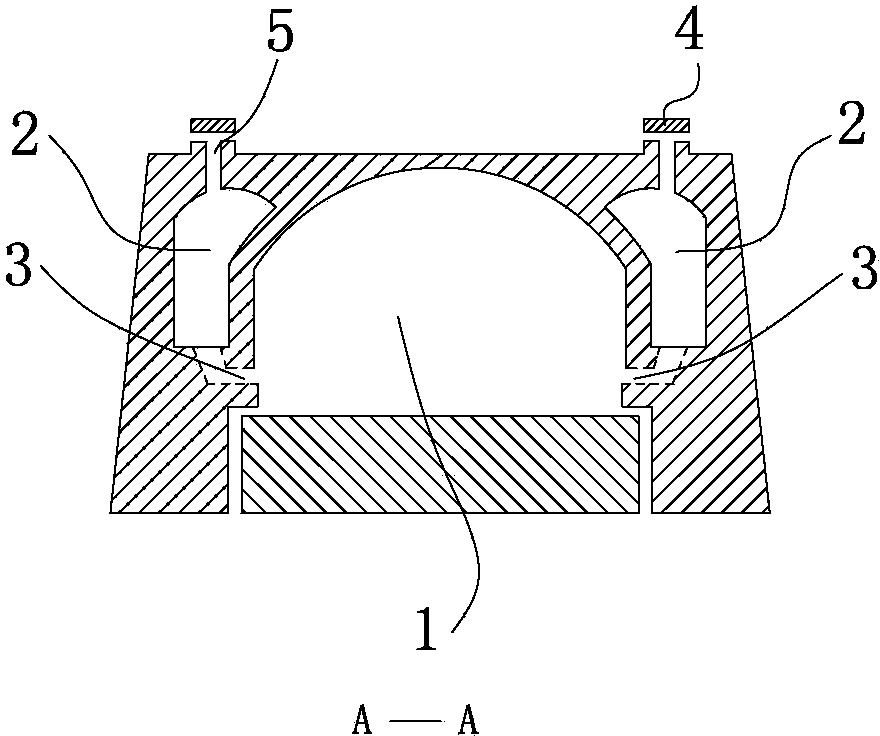

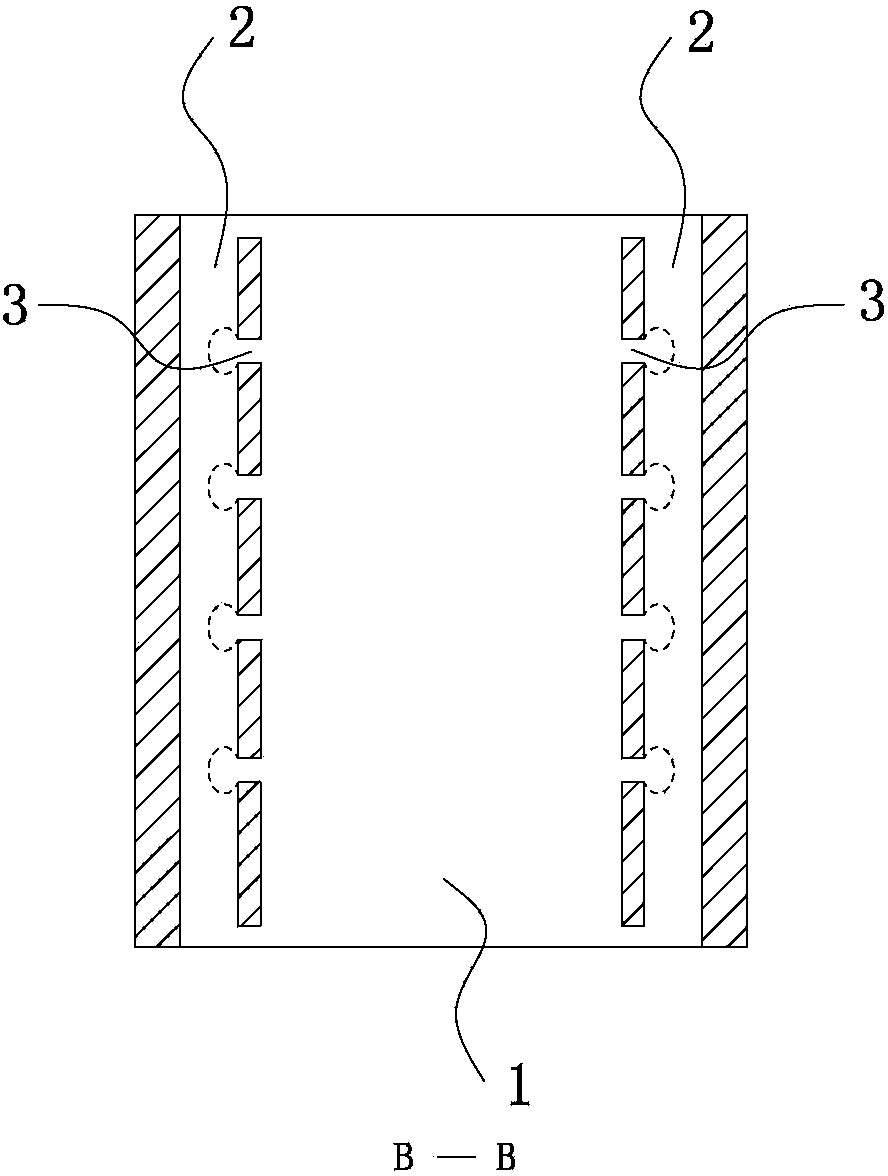

Desulfuration and impurity removal device and process of tunnel kiln exhaust gas

ActiveCN102829624AEfficient desulfurization and impurity removalWith filtering effectFurnace typesWaste heat treatmentTunnel kilnCold air

The invention relates to the technical field of waste gas treatment, and particularly relates to a desulfuration and impurity removal device and process of tunnel kiln exhaust gas. The process comprises the following steps that: A. part of exhaust gas generated in a high temperature baking area is introduced pinto a drying buffer area, the exhaust gas passes through a brick mesh of the drying buffer area and is then discharged from an exhaust gas collection channel; B. another part of exhaust gas generated in the high temperature baking area enters a side air duct through an air duct port, a ventilating gate is opened, cold air outside a tunnel kiln enters the side air duct through a ventilating gate port and is mixed with the exhaust gas in the side air duct, and the mixed exhaust gas enters the high temperature baking area again through the air duct port; C. the ventilating gate is closed, the exhaust gas enters the side air duct through the air duct port, and when the mixed exhaust gas reaches the side air duct of a drying area, the mixed exhaust gas is pumped from the air duct port to the drying area, and the mixed exhaust gas passes the brick mesh of the drying area; and D. the exhaust gas is pumped by a exhaust fan and discharged from the exhaust gas collection channel. The desulfuration and impurity removal device and process of tunnel kiln exhaust gas provided by the invention is good in a dedusting effect and high in desulfuration efficiency, and the sulfur content of the exhaust gas is reduced by 80%-90%.

Owner:黎志登 +1

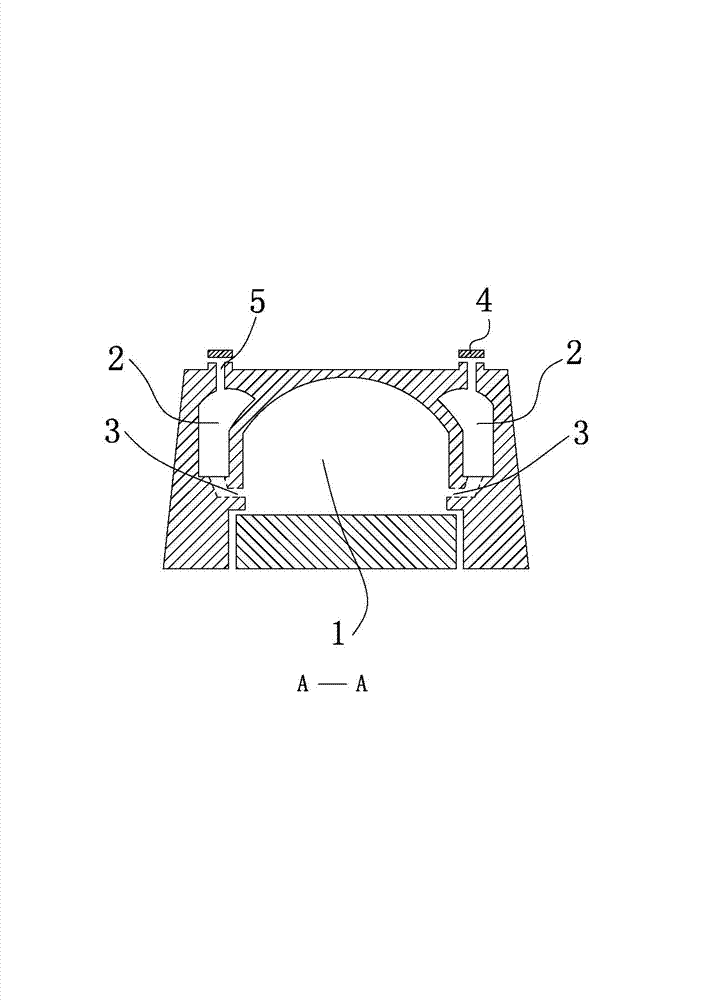

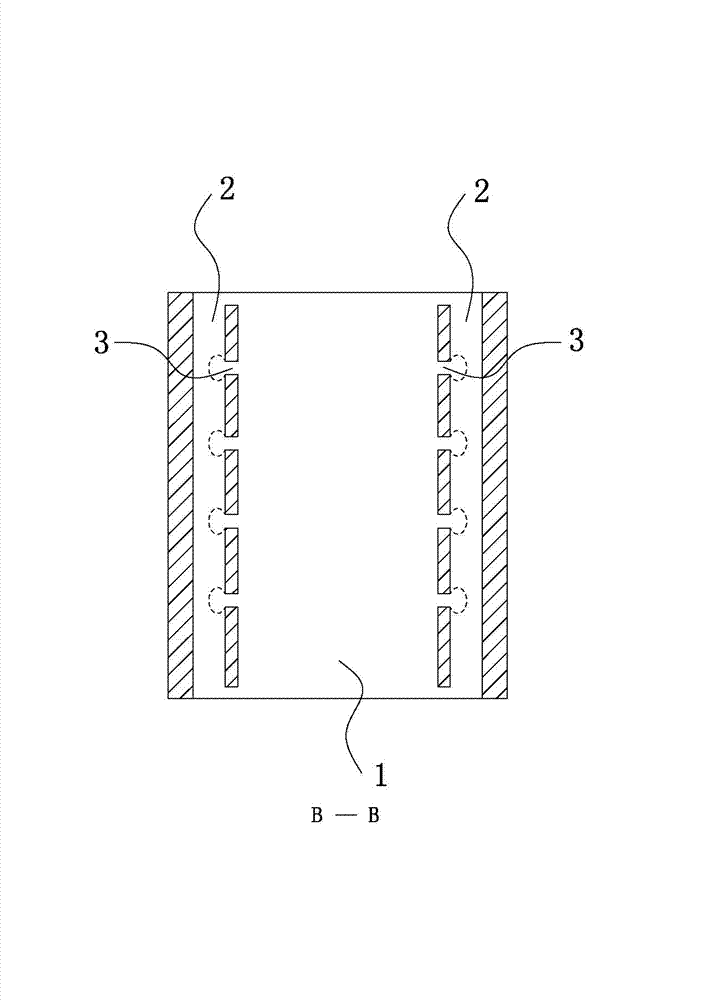

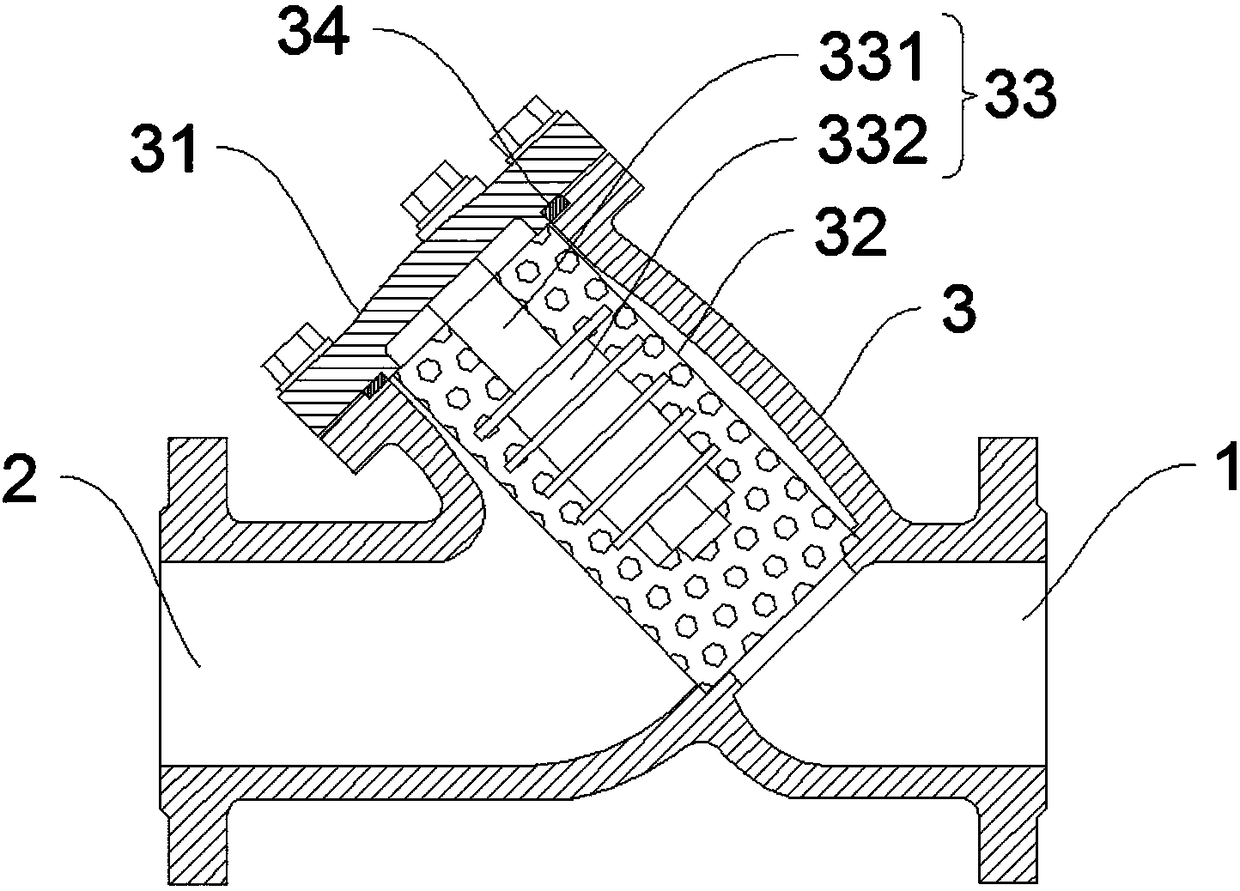

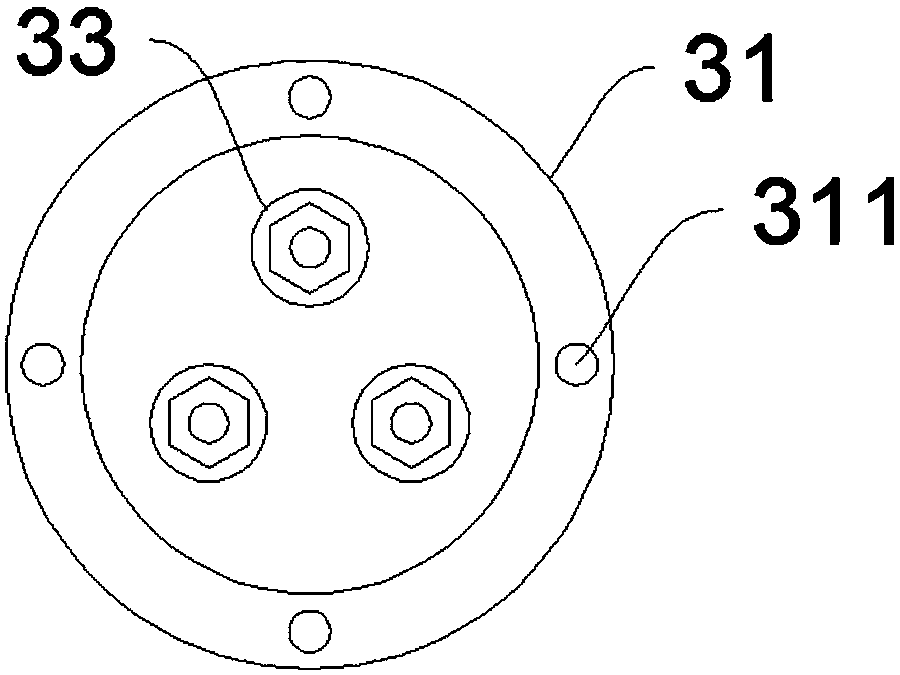

Y-type magnetic filter

PendingCN108159773AIsolated magnetizationImprove adsorption capacityFiltration separationParticulate pollutionEngineering

The invention belongs to the technical field of y-shaped filters, and particularly relates to a Y-type magnetic filter. The Y-type magnetic filter comprises a side barrel arranged on a side wall, wherein a barrel cover is arranged at the top of the side barrel; a cylindrical filter screen is inserted into the side barrel; at least one magnetic component is arranged on the internal surface of the barrel cover and located in the filter screen; the magnetic components comprise fixing bars made from nylon materials and magnetic blocks; the fixing bars are sleeved with the magnetic blocks; the magnetic blocks are of cylindrical structures with through holes in the middles and are made from plastic magnets; a non-asbestos gasket is arranged between the barrel cover and the upper surface of the side barrel for sealing; and the filter has a good effect of absorbing iron particulates and does not generate magnetic particulate pollution media.

Owner:池州市日升阀门管件制造有限公司

Pressure equalizing bidirectional filter and working method thereof

ActiveCN104906865ASolve the difficult problem of automatic backwashingNo lossLoose filtering material filtersGravity filtersWater qualityEngineering

The invention discloses a pressure equalizing bidirectional filter and a working method thereof. The filter comprise a communicating main pipe, communicating branch pipes, a backwashing drain pipe, a blow-down pipe, a filtering column and a filtering column base, wherein a communicating main pipe butterfly valve is arranged on the communicating main pipe; the upper end of the side face of the filtering column is connected with the upper section of the communicating main pipe by the upper communicating branch pipe; the top of the filtering column is connected with the backwashing drain pipe; the lower part of the filtering column is connected with the filtering column base; the side face of the upper part of the filtering column base is connected with the lower section of the communicating main pipe by the lower communicating branch pipe; an upper communicating branch pipe butterfly valve is arranged in the upper communicating branch pipe; a lower communicating branch pipe butterfly valve is arranged in the lower communicating branch pipe; a homogeneous filter material is filled into the filtering column; and the lower part of the filtering column base is connected with the blow-down pipe. By using the working method of the pressure equalizing bidirectional filter, an automatic balancing procedure is adopted in normal operation, and impurities in the filtering column can be cleared by performing a water filling replacing procedure at regular times. According to the invention, pressure of two water phases, namely inside water phase and outside water phase, can be dynamically balanced, water qualities are not affected by each other, and no pressure difference is formed between inside water phase and outside water phase.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

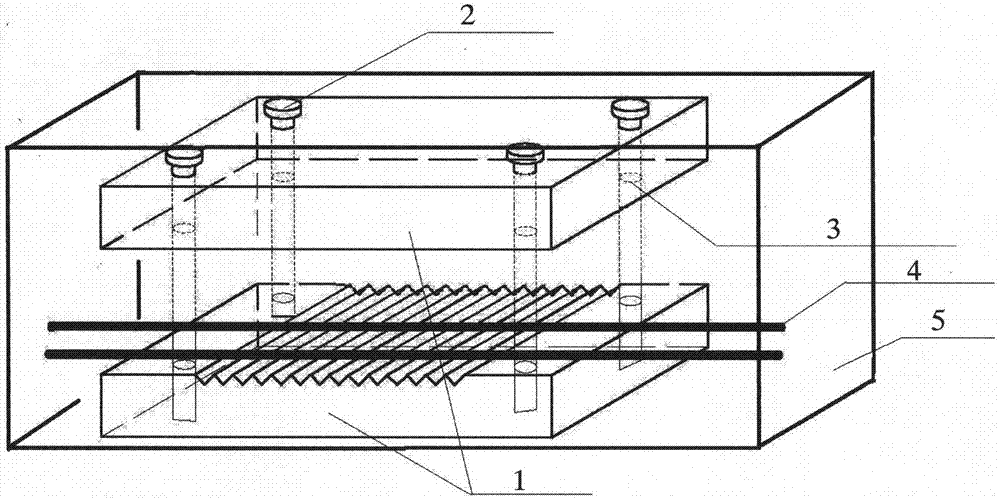

Tunable optical-fiber filter

InactiveCN103760688AErasableChange the degree of attenuationNon-linear opticsUltrasound attenuationGrating

The invention belongs to the technical field of optical fiber sensing, and particularly relates to a tunable optical-fiber filter. Two V-shaped groove serrate plates with long cycle and equal interval are used to apply stress to single-mode optical fibers so as to form a long-cycle grating. After the long-cycle grating is placed in a thermostatic chamber, temperature is changed through a thermostatic oven, and wavelength of filter wave is changed as needed. Since the two V-shaped groove serrate plates with long cycle and equal interval apply stress to the single-mode optical fibers after being fixed with screws, attenuation degree of light wave intensity is regulated on the condition of keeping the central wavelength of resonance wave constant, and filtering performance is improved. The tunable optical-fiber filter capable of changing wavelength of the filter wave and attenuation degree of light intensity simultaneously is simple in structure and has erasability.

Owner:CHINA JILIANG UNIV

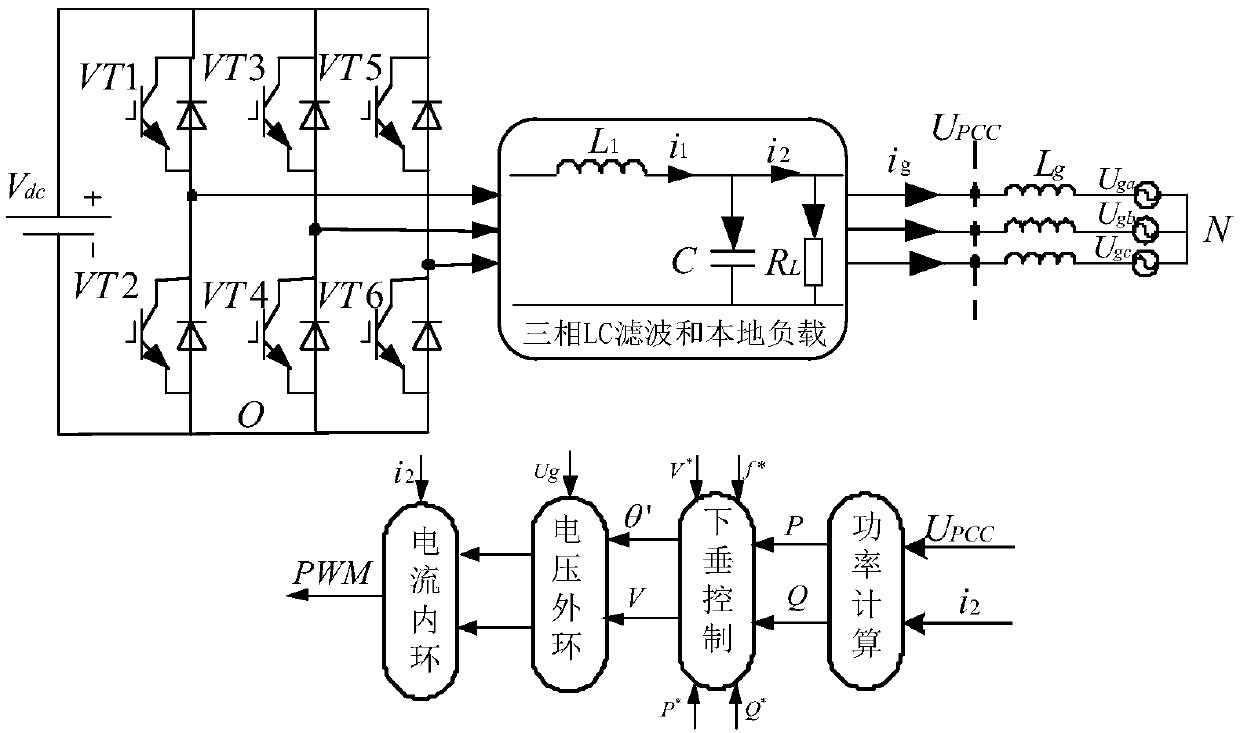

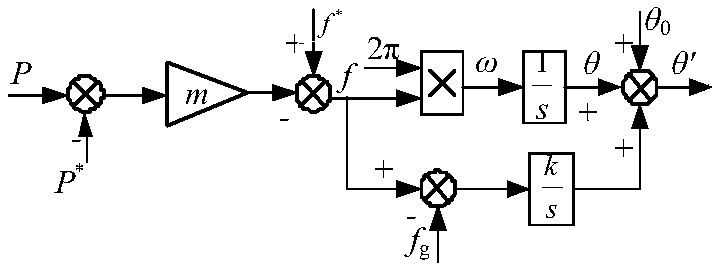

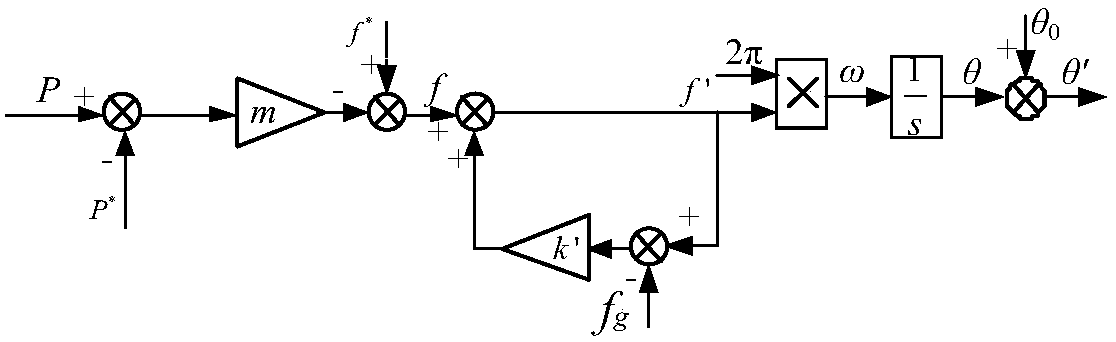

Island detection method for droop control grid-connected inverter

InactiveCN107947240AIncrease the magnitude of changeBig changeElectrical testingSingle network parallel feeding arrangementsVoltage amplitudePower flow

The invention discloses an island detection method for a droop control grid-connected inverter. The method is implemented specifically according to the following steps: 1, a three-phase grid-connectedinverter main circuit system is built; 2, output active power and reactive power of the three-phase grid-connected inverter are calculated; 3, an improved P-f droop controller with disturbance k(f-f<g>) / s added is utilized to calculate reference output of voltage amplitude and phase; 4, difference between the reference voltage and phase and actual voltage and phase is calculated to obtain an error voltage value as reference input of an outer ring regulator, output of the regulator is reference input of inner ring current, difference between the reference input of the inner ring current and actual current is calculated to obtain an error current value as input of an inner ring regulator, and finally, an output modulation signal is obtained; and 5,the value of |d[delta][theta] / dt|=|k(f-f<g>)| is monitored in real time to perform island judgment. According to the island detection method for a droop control grid-connected inverter, on the basis of a traditional island monitoring droop improvement method, integration is added for the disturbance part, the amplitude of |d[delta][theta] / dt| is increased and stable amplitude is maintained, thereby avoiding island misjudgment.

Owner:YANSHAN UNIV

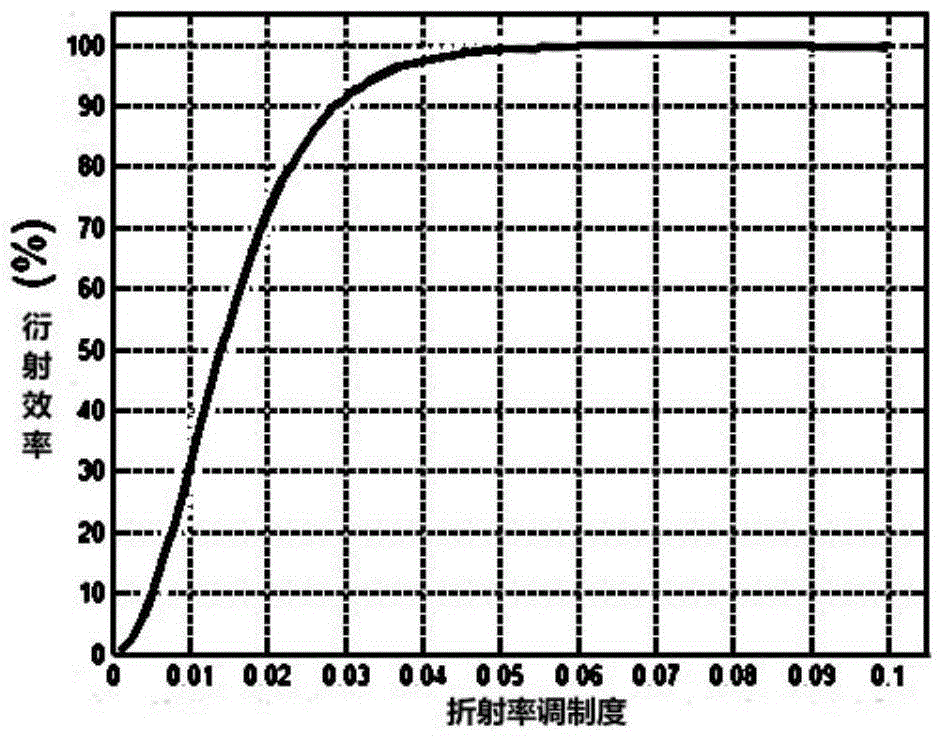

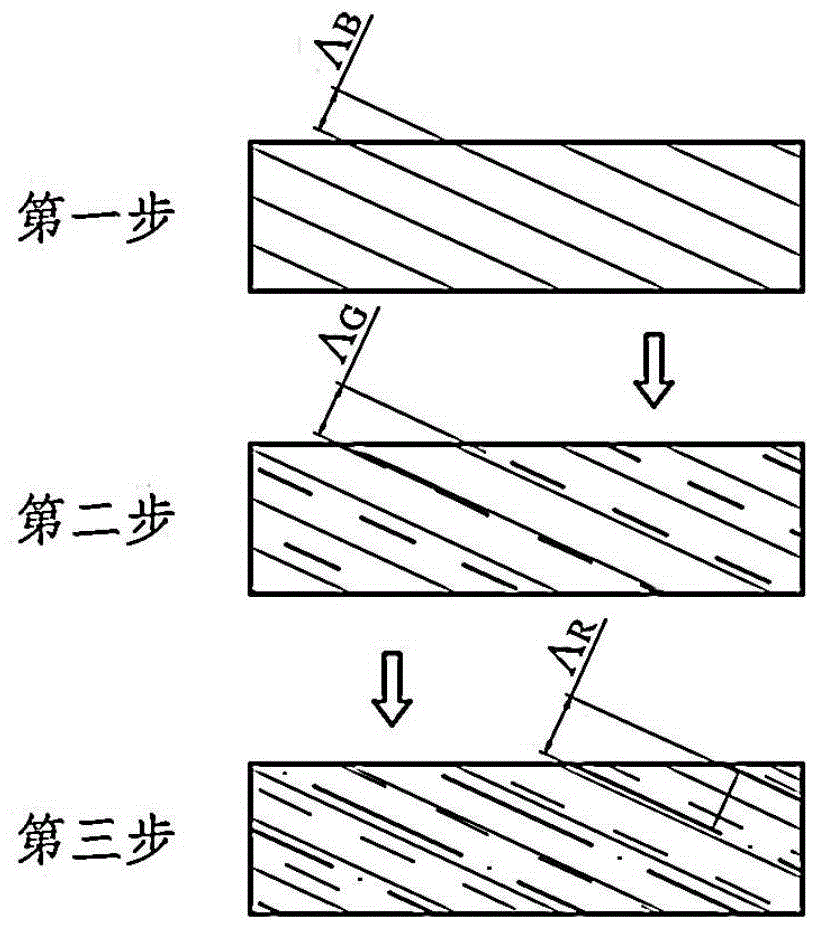

A kind of multiplexing volume holographic grating

The invention discloses a multiplexed volume holographic grating. The multiplexed volume holographic grating respectively records red, green and blue three holograms on the same dielectric layer by exposing for three times; volume holographic gratings formed by exposure of different wavelengths are the same in inclination angle and are different in period; by controlling exposure time, refractive index modulation depths corresponding to red, green and blue light after exposure accords with the relation that delta n red light is greater than delta n green light, and delta n green light is greater than delta n blue light, and peak diffraction efficiencies corresponding to the red, green and blue light after exposure are similar. The multiplexed volume holographic grating can effectively balance irradiating energy of red, green and blue light waves and avoid color offset.

Owner:SOUTHEAST UNIV

High-efficiency and low-resistance air filter material made of special-shaped melt-blown fibers

The invention discloses a high-efficiency low-resistance air filter material prepared form special-shaped melt-blown fiber and a preparation method of the high-efficiency low-resistance air filter material. The high-efficiency low-resistance air filter material is characterized in that a coarse filtration part, a supporting part and a fine filtration part are sequentially arranged from top to bottom to form a filter material adopting a sandwich structure; needling is performed under the conditions that the needling depth ranges from 5 mm to 7 mm and the needling density ranges from 390 needles per cm<2> to 480 needles per cm<2>, and all parts of the filter material are connected to form the high-efficiency low-resistance air filter material; the coarse filtration part and the fine filtration part are made from chemical fiber and combed into net-shaped structure, and the supporting part is made from the special-shaped melt-blown fiber. The high-efficiency low-resistance air filter material has high filter efficiency, the filter resistance is lower, the manufacturing cost is low, and the process is simple and environment-friendly; the special-shaped melt-blown fiber is used for preparing the filter material for the first time, and a great breakthrough is made in the field of filter materials.

Owner:DONGHUA UNIV

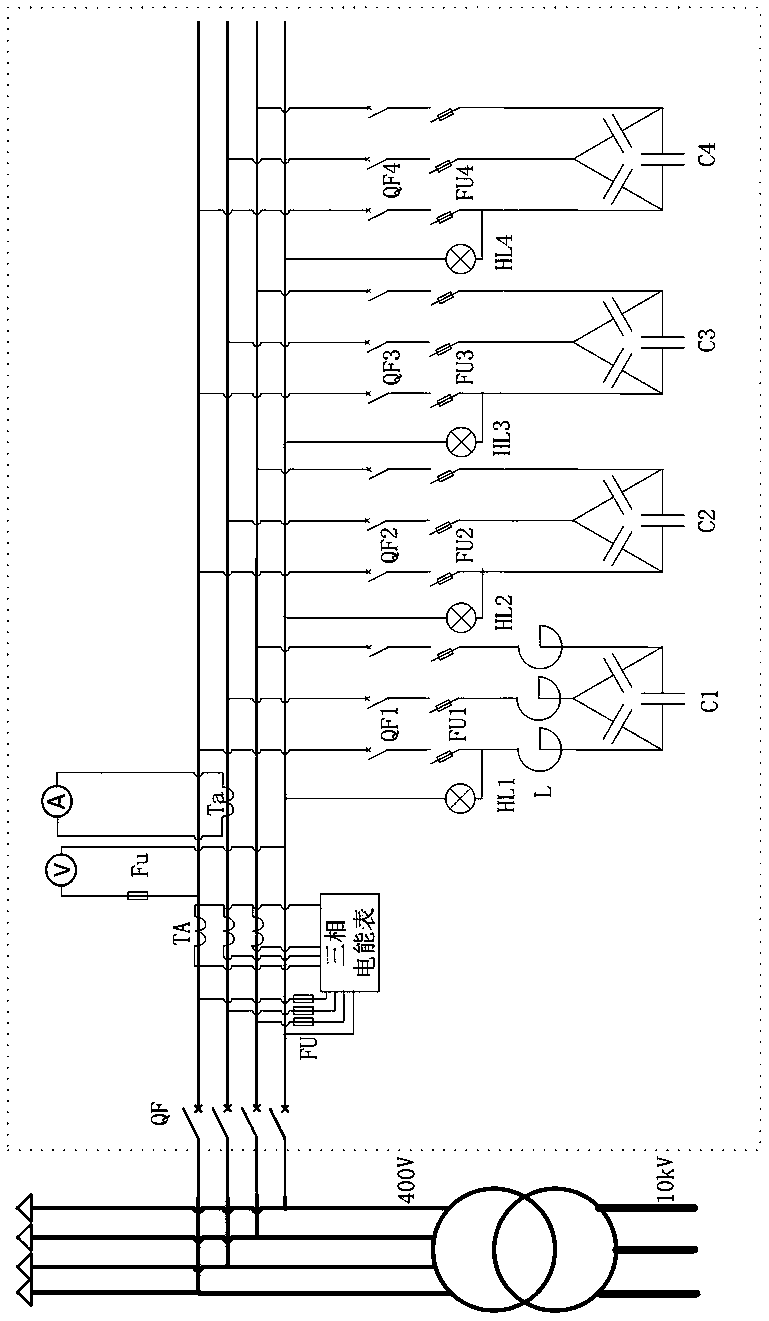

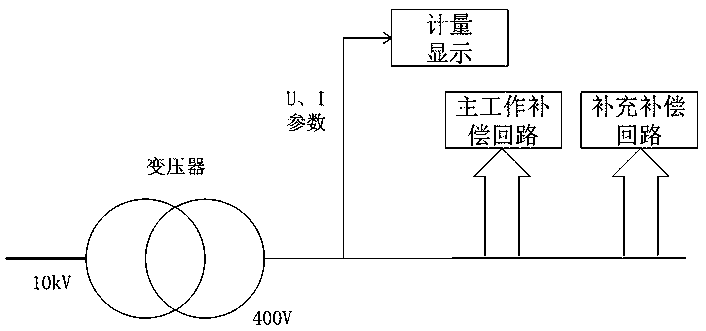

A reactive power compensation device for no-load transformer based on high supply and high meter

InactiveCN109088412AAvoid Harmonic AmplificationHigh compensation accuracyEnergy industryReactive power adjustment/elimination/compensationHigh pressurePower regulation

A reactive power compensation device of no-load transformer based on high supply and high meter is composed of a main working compensation loop, a supplementary compensation loop and da isplay metering loop. The main working loop can not only achieve the effect of reactive power compensation, but also effectively avoids the harmonic resonance. Supplementary compensation circuit can improve the compensation precision of high voltage side of transformer. The invention makes up for the defect that the reactive power compensation of the load carried by the enterprise can not be switched on and offwhen the transformer is no load, improves the compensation precision and improves the power factor when the low voltage side of the transformer is no load. Whether or not the transformer is in a large load state or no load state, the power factor measured at the high-voltage side of the transformer can be kept above 0.9, so the power regulation fee penalty can be effectively avoided, and the power consumption cost of the enterprise is reduced.

Owner:广州峰控电力科技有限公司

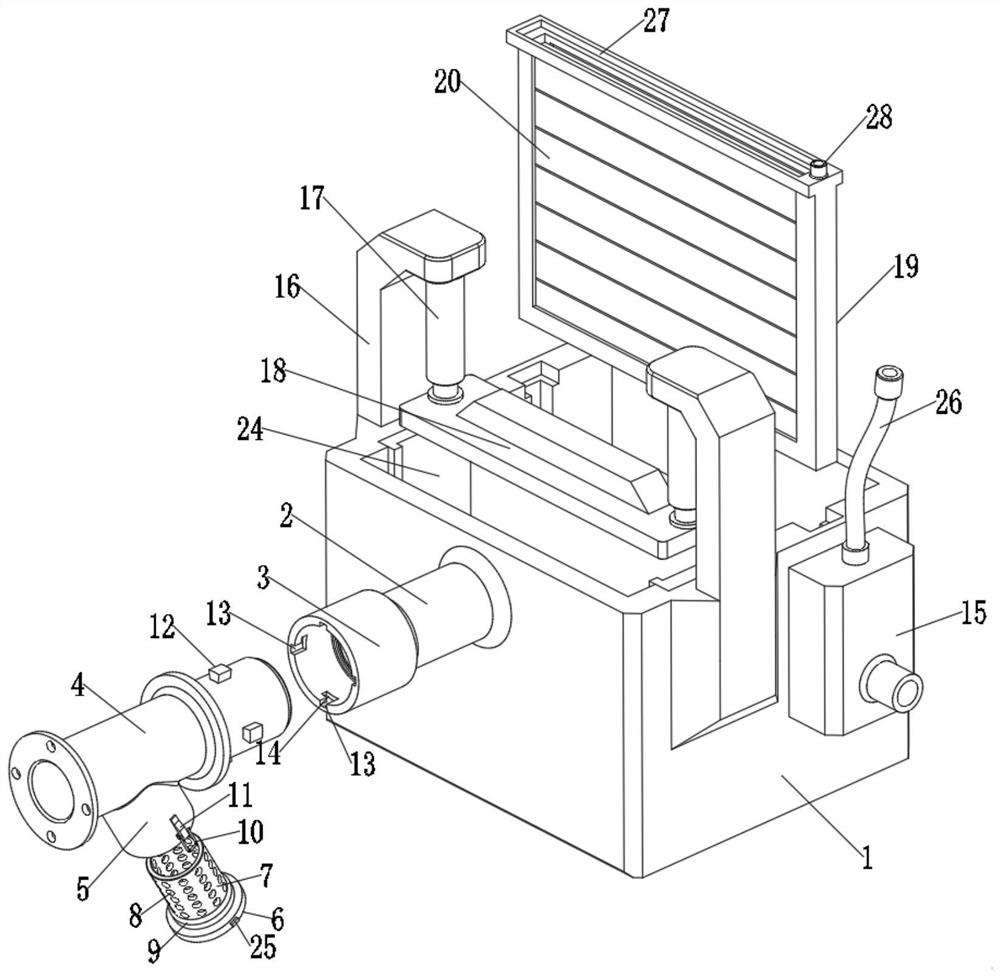

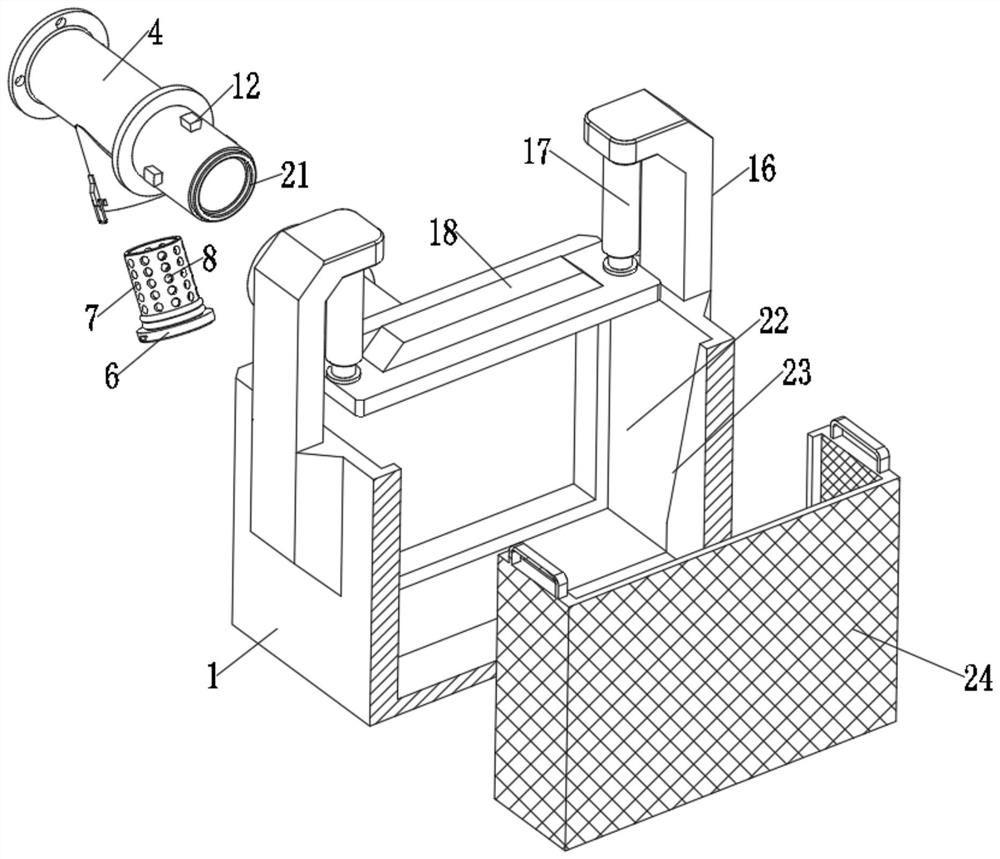

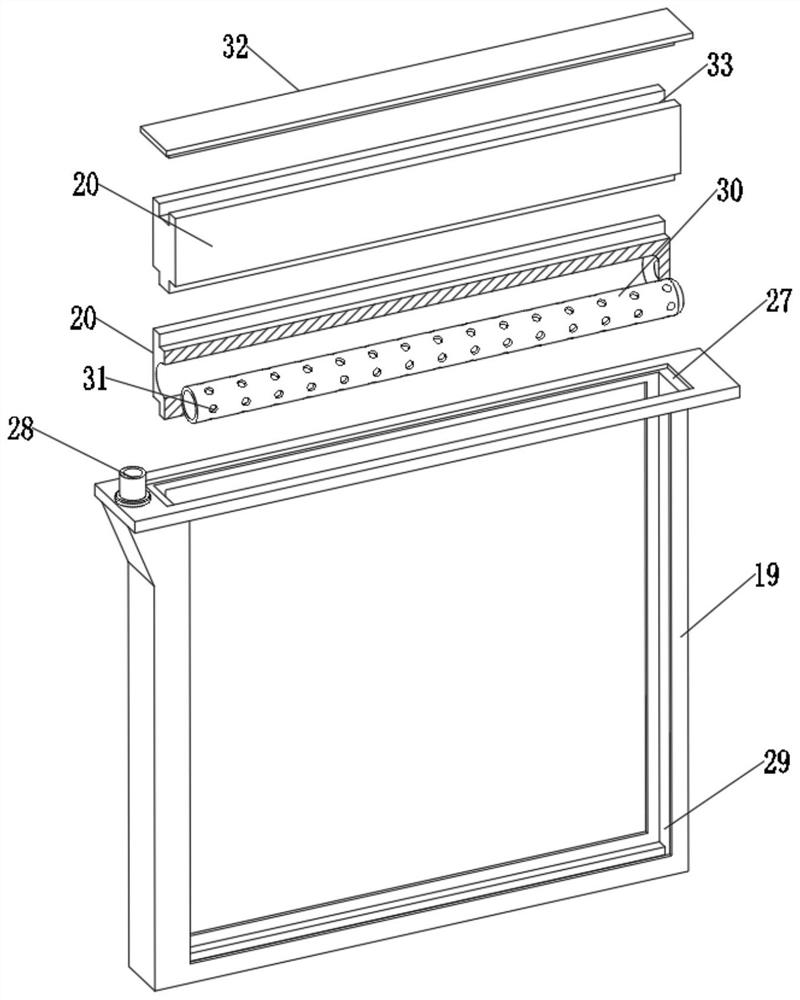

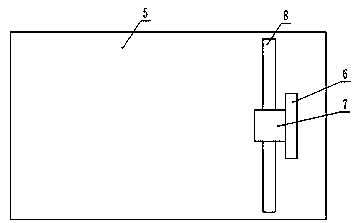

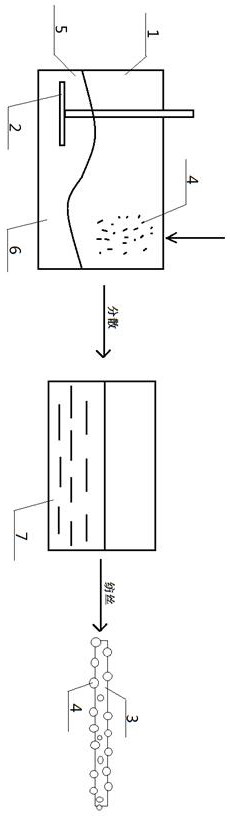

Curtain type sewage treatment equipment and use method thereof

PendingCN114669104AIncreased speed of entry into the interior of the filter plateSpeed up filteringMembrane filtersStationary filtering element filtersSewageSewage treatment

The invention relates to the technical field of curtain type sewage treatment, and discloses curtain type sewage treatment equipment and a using method thereof.The curtain type sewage treatment equipment comprises a box body and a suction vacuum pump on one side of the box body, an external hose is installed at the upper end of the suction vacuum pump, a liquid inlet pipe is arranged on one side of the box body, and a liquid outlet pipe is arranged on the other side of the box body; supporting frames are symmetrically arranged at the upper end of the box body, hydraulic shafts are installed on one sides of the supporting frames, pressing plates are installed at the lower ends of the two hydraulic shafts, a filtering frame is installed in the box body, a limiting groove is formed in the top end of the filtering frame, a sealing cover plate is installed in the limiting groove, and a limiting inner groove is formed in the filtering frame. When sewage preliminarily enters an external pipeline and has more internal impurities, the filtering pipe is matched with the supporting base, so that the impurities in the sewage are filtered, the situation that the impurities flow into the subsequent process and the filtering load is increased is avoided, and the working intensity of a subsequent structure is relieved.

Owner:王成林

Heavy metal tailing dry discharge system

PendingCN114272650ANormal precipitationSave man hoursSettling tanks feed/dischargeCentrifugal force sediment separationElectric machineryStructural engineering

The invention discloses a heavy metal tailing dry discharge system which comprises a tank body, a rake arm arranged on the extension of a rotating shaft, an outer discharge pipe arranged at the bottom of the tank body, a sleeve arranged at the bottom of an operation table, a liquid injection pipe arranged on the operation table, a frustum arranged on the outer wall of the rotating shaft, and a plurality of sliding grooves formed in the outer wall of a generatrix of the frustum. A plurality of partition plates are arranged on the inner circumferential wall of the tank body in the circumferential direction of the tank body, and the horizontal height of the lower end face of the frustum is larger than that of the lower end faces of the partition plates. When the device is normally used or restarted after shutdown overhaul, it can be ensured that ore pulp in the tank body can be normally precipitated, the floating displacement of flocculated large particles is reduced by limiting the floating movement of the silt layer located at the bottom of the tank body and located above the rake arm, and the flotation effect of the large particles is improved. Therefore, the working hours of returning the ore pulp to the layering state when the motor is restarted after shutdown maintenance are reduced.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

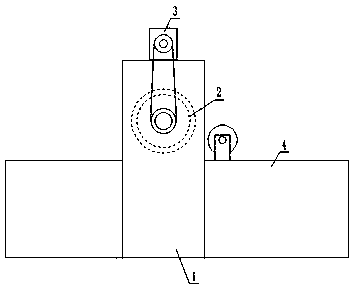

A blind ditch production equipment and process

ActiveCN108501491BGood adhesionNo sheddingLamination ancillary operationsLaminationEngineeringStructural engineering

The invention relates to blind ditch production equipment and technology. The blind ditch production equipment comprises a heat sealing machine, an edge cutting machine, a film laminating machine, anda heat recessing machine which are sequentially arranged, wherein the heat sealing machine is used for combining a plastic mesh with geotechnical cloth together to form a composite layer; the edge cutting machine is used for cutting the composite layer; the film laminating machine is used for applying the composite layer onto the surface of a bland ditch; the heat recessing machine is used for forming slots in two ends of the bland ditch, and comprises an operation platform, a blind ditch mounting support, a recessing device, and a back-and-forth movement driving mechanism of the recessing device, wherein the recessing device comprises a moving platform and two heating sheave wheels which are symmetrically arranged at the left end and the right end of the moving platform; and electric heating devices are respectively arranged in the heating sheave wheels. Compared with the prior art, the blind ditch production equipment disclosed by the invention has the advantages that the compositelayer is firmly bonded to the surface of the blind ditch, so that the phenomenon that the composite layer falls off is avoided; and the integral structural strength of the blind ditch is enhanced, sothat the blind ditch cannot be damaged under higher pressure.

Owner:济南金利源环保科技股份有限公司

Desulfuration and impurity removal device and process of tunnel kiln exhaust gas

ActiveCN102829624BEfficient desulfurization and impurity removalWith filtering effectFurnace typesWaste heat treatmentTunnel kilnCold air

The invention relates to the technical field of waste gas treatment, and particularly relates to a desulfuration and impurity removal device and process of tunnel kiln exhaust gas. The process comprises the following steps that: A. part of exhaust gas generated in a high temperature baking area is introduced pinto a drying buffer area, the exhaust gas passes through a brick mesh of the drying buffer area and is then discharged from an exhaust gas collection channel; B. another part of exhaust gas generated in the high temperature baking area enters a side air duct through an air duct port, a ventilating gate is opened, cold air outside a tunnel kiln enters the side air duct through a ventilating gate port and is mixed with the exhaust gas in the side air duct, and the mixed exhaust gas enters the high temperature baking area again through the air duct port; C. the ventilating gate is closed, the exhaust gas enters the side air duct through the air duct port, and when the mixed exhaust gas reaches the side air duct of a drying area, the mixed exhaust gas is pumped from the air duct port to the drying area, and the mixed exhaust gas passes the brick mesh of the drying area; and D. the exhaust gas is pumped by a exhaust fan and discharged from the exhaust gas collection channel. The desulfuration and impurity removal device and process of tunnel kiln exhaust gas provided by the invention is good in a dedusting effect and high in desulfuration efficiency, and the sulfur content of the exhaust gas is reduced by 80%-90%.

Owner:黎志登 +1

Process for producing wax-crystal dispersing auxiliary with diesel oil at low-temperature and uses thereof

InactiveCN101219951ARaw materials are readily availableSimple production processOrganic compound preparationCarboxylic acid esters preparationCarbon numberCarboxylic acid

A method for preparing a diesel low temperature wax crystal disperser and the application of the disperser belongs to the field of disperser. The preparation method is as follows: mixing an organic carboxylic acid and an aliphatic amine or an aliphatic alcohol according to a quantity ratio of 1:1.5 to 3:1; taking toluene or xylene as a solvent, reacting for 2 to 5 hours at a temperature of 60 DEG C to 150 DEG C, steaming out the solvent to get the disperser. When reacting with aliphatic amine, a needed catalyst is a toluene sulfonic acid. The organic carboxylic acid is a p-tert-butylbenzoic acid or a mixture of dodecanoic acid, myristic acid, hexadecanoic acid and stearic acid according to a quantity ratio of 1:1.15:1.3:1.45. The carbon number of aliphatic amine or aliphatic alcohol is C3 to C8; a blending temperature of the disperser and the present sold diesel low temperature flow modifier is 50 DEG C to 120 DEG C; the quantity ratio is 1:1 to 1:4. The cooperation of the dispersers and the present domestic diesel low temperature flow modifier can more effectively reduce the cold filter plugging point of long distillate diesel and has a certain sensitivity to narrow fraction diesel.

Owner:BEIJING UNIV OF CHEM TECH

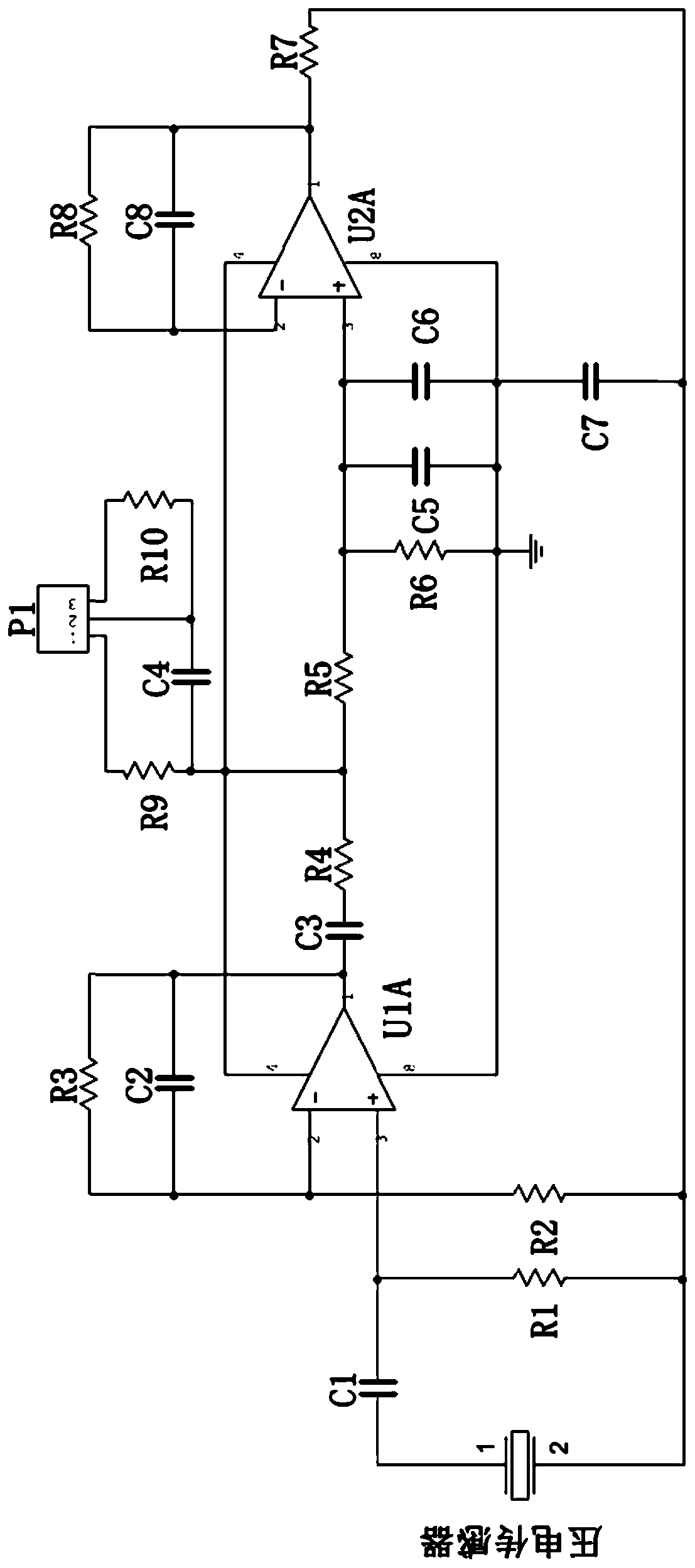

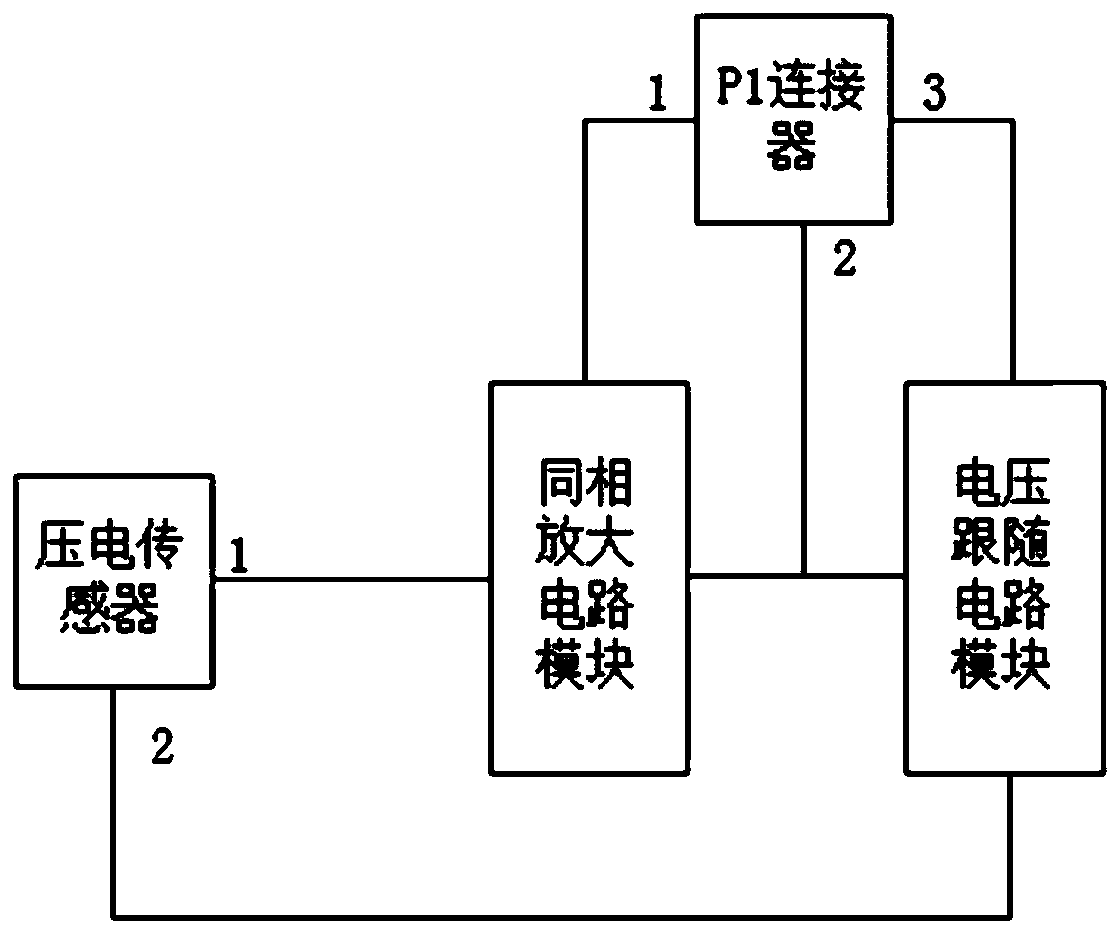

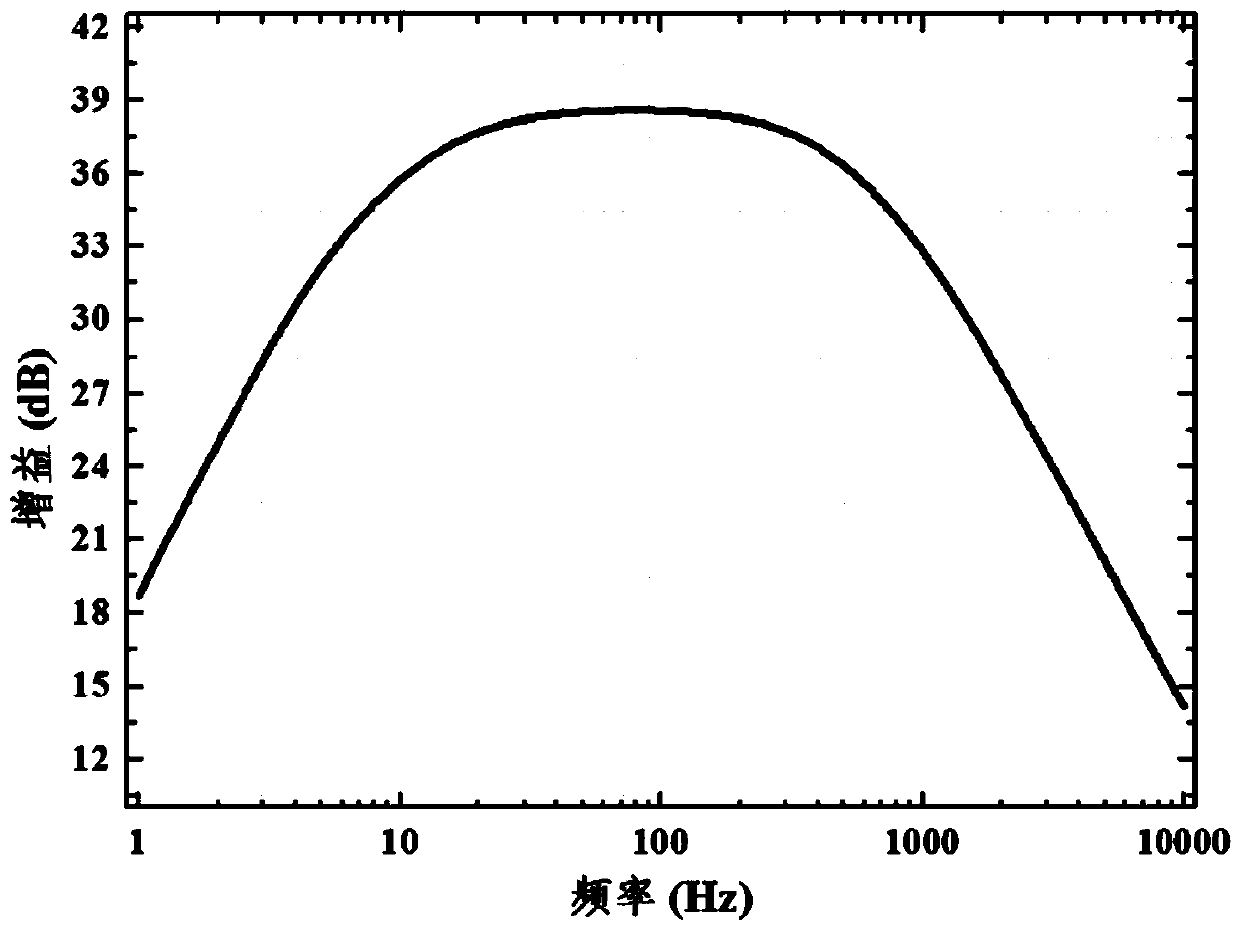

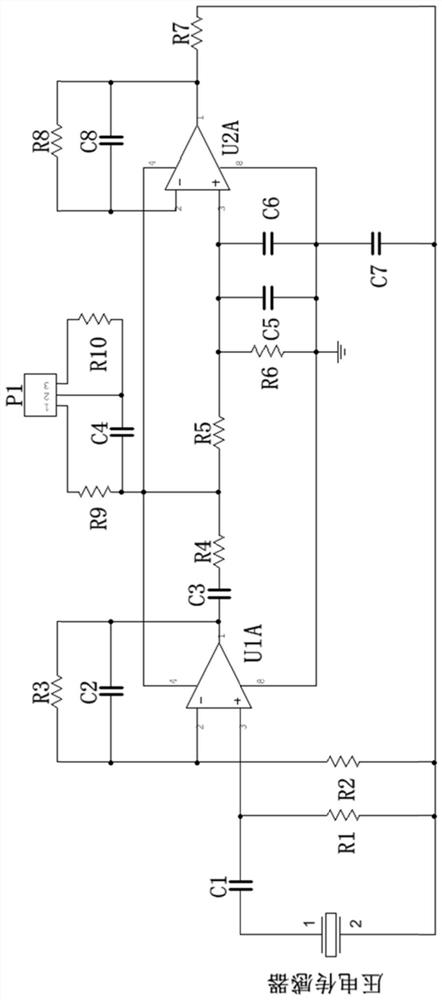

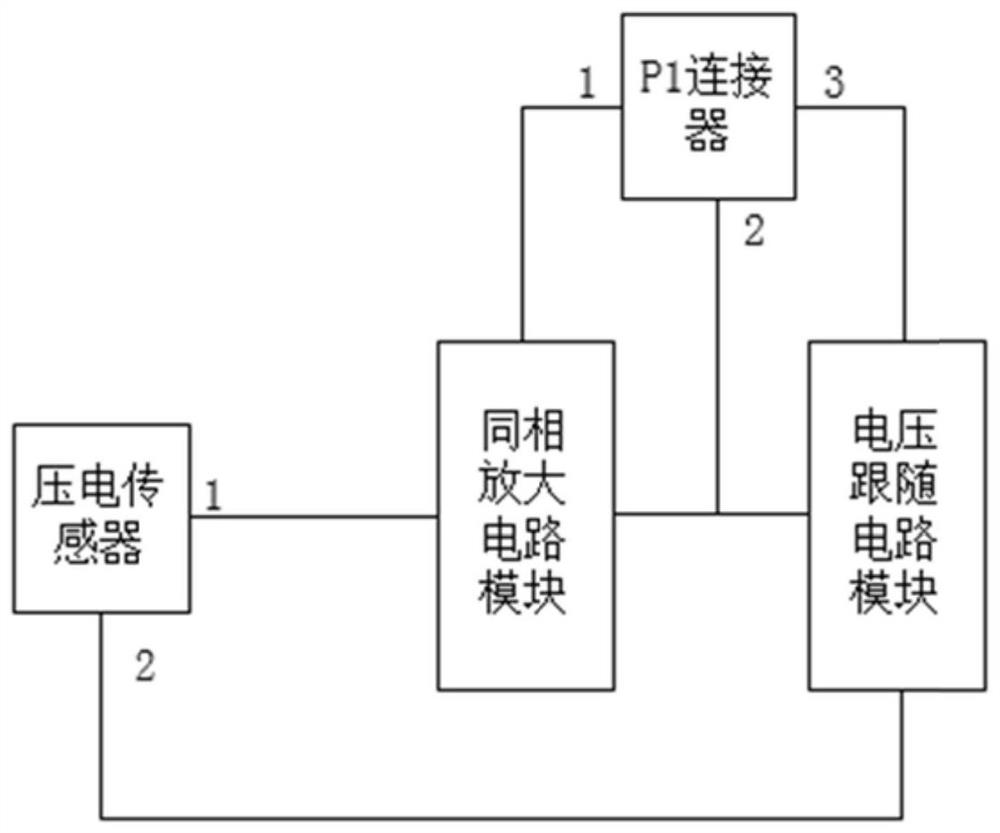

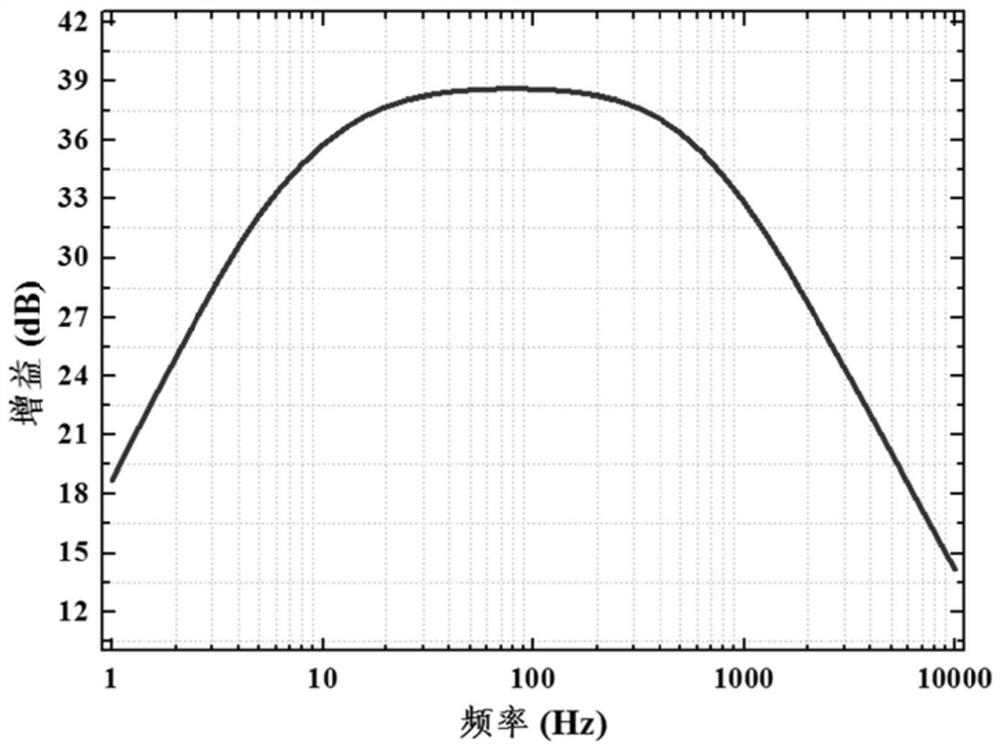

Echo amplification circuit of low-noise MEMS piezoelectric hydrophone

ActiveCN111431493AImprove stabilityImprove signal-to-noise ratioWave based measurement systemsAmplifier modifications to reduce noise influenceLow noiseHydrophone

The invention discloses an echo amplification circuit of a low-noise MEMS piezoelectric hydrophone. The echo amplification circuit mainly comprises an non-inverting amplification circuit and a voltagefollower circuit. The circuit is powered by an accurate voltage source. A proper static potential is provided for the non-inverting amplification circuit by using the follower circuit through resistance voltage division; by selecting an operational amplifier with low equivalent input noise voltage and low equivalent input noise current and reasonably selecting an external resistor, the echo amplification circuit has a certain filtering effect, meanwhile, the equivalent input noise of the circuit is reduced, and the signal-to-noise ratio of the signal is further improved. The circuit is convenient to adjust the static working point of the amplification circuit, the circuit is simplified by means of power supply of a single power supply, good in circuit stability, few in used devices, low in cost, convenient to connect with an external circuit due to the fact that input and output share the same interface, convenient to operate and certain in application value.

Owner:ZHEJIANG UNIV

A low-noise mems piezoelectric hydrophone echo amplifier circuit

ActiveCN111431493BImprove stabilityImprove signal-to-noise ratioWave based measurement systemsAmplifier modifications to reduce noise influenceLow noiseHydrophone

The invention discloses an echo amplifying circuit of a low-noise MEMS piezoelectric hydrophone. The echo amplifying circuit mainly includes a non-inverting amplifying circuit and a voltage following circuit. The circuit is powered by a precise voltage source, and the follower circuit provides a suitable static potential for the non-inverting amplifying circuit through resistor division. By selecting an operational amplifier with low equivalent input noise voltage and low equivalent input noise current and conducting external resistance Reasonable selection enables the echo amplifier circuit to have a certain filtering effect while reducing the equivalent input noise of the circuit and further improving the signal-to-noise ratio of the signal. The circuit is convenient to adjust the static operating point of the amplifying circuit, the single power supply simplifies the circuit, the circuit has good stability, uses few components, and is low in cost.

Owner:ZHEJIANG UNIV

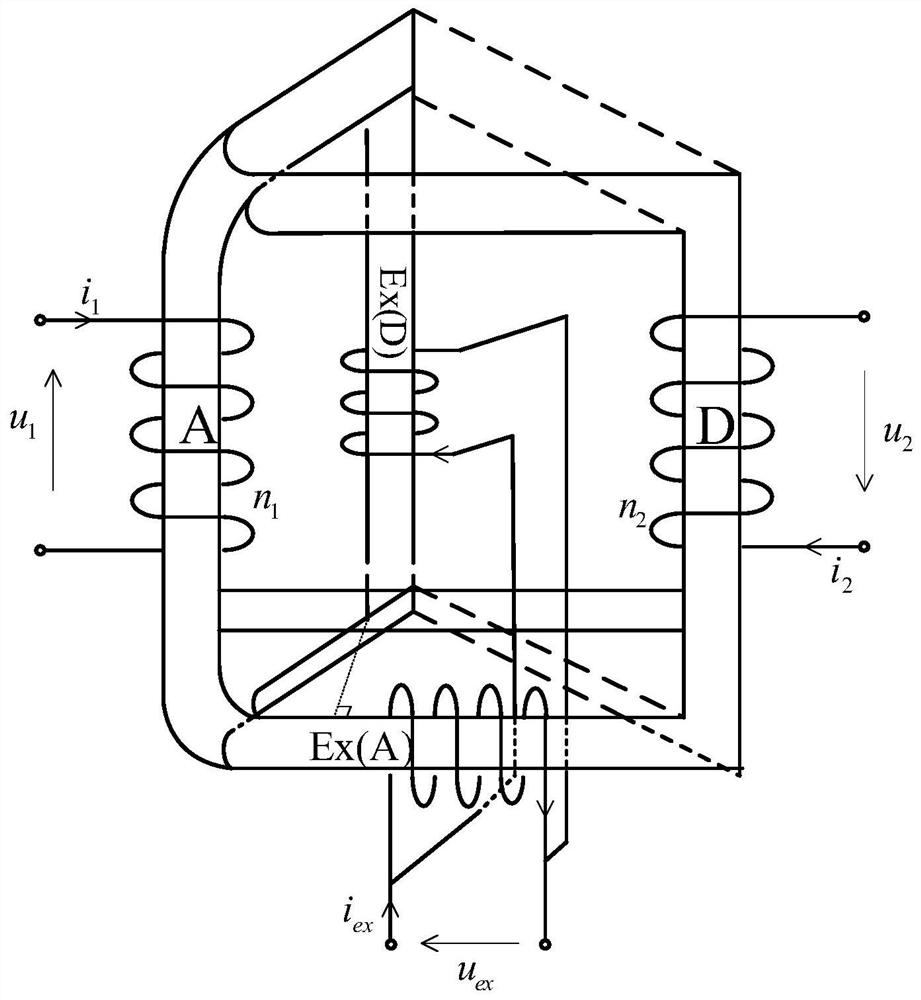

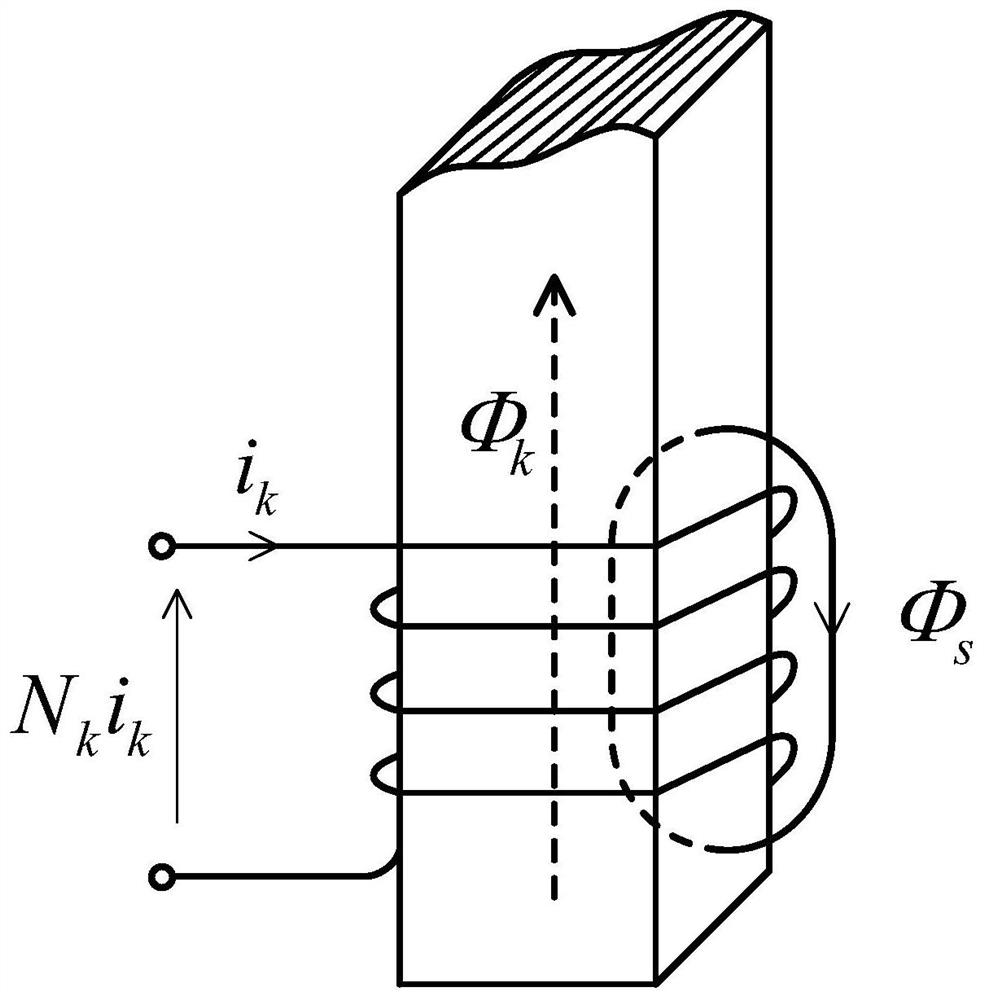

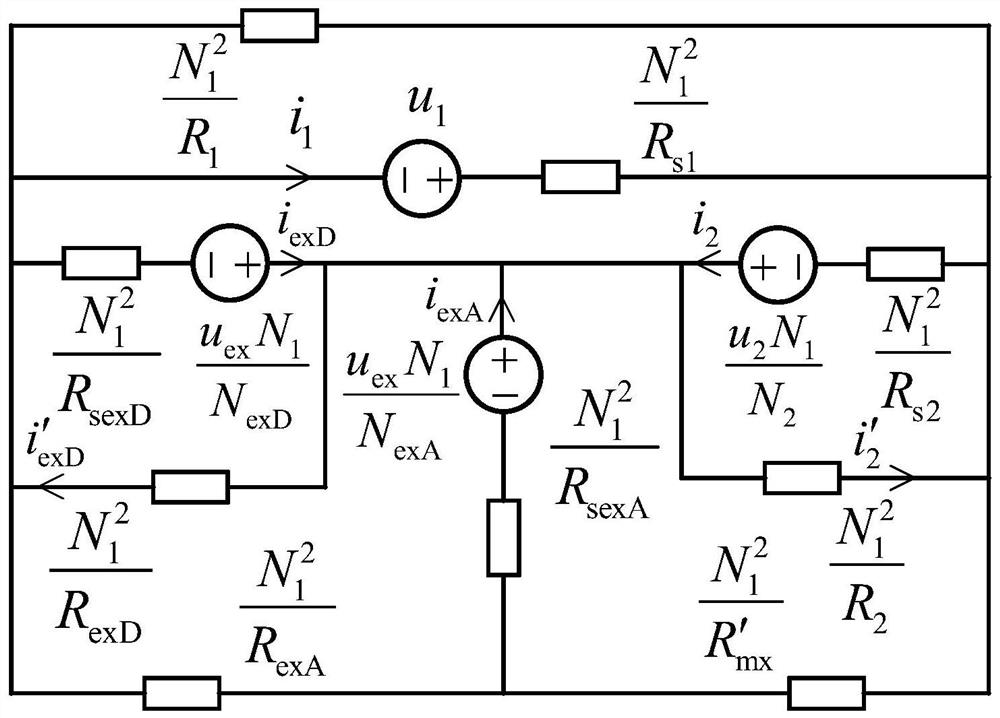

Extra-high-voltage converter transformer with filtering function

ActiveCN112259336AWith filtering effectAvoid commutation failureTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerHigh-voltage direct current

The invention provides an extra-high-voltage converter transformer with a filtering function. A making method of the extra-high-voltage converter transformer with the filtering function comprises thefollowing steps that S1, the converter transformer of an extra-high-voltage direct-current power transmission system serves as an object, and the magnetic circuit saturation condition and the harmoniccirculation condition of the converter transformer are taken into consideration, wherein a circuit magnetic circuit analysis structure of a single iron core column is included; and S2, the magnetic circuit distribution and a circuit structure of the converter transformer are taken into consideration, and a four-winding type converter transformer electromagnetic coupling circuit and an electromagnetic coupling circuit equivalent circuit model according to an extra-high voltage direct current power transmission operation scene. The extra-high-voltage converter transformer with the filtering function is suitable for an extra-high-voltage direct-current power transmission system, and has a harmonic filtering function while having voltage matching and electrical isolation functions of a commonconverter transformer, so the grid-side harmonic and reactive burdens of an existing extra-high-voltage direct-current power transmission project converter transformer are reduced, and the reliability of the extra-high-voltage direct-current power transmission project is improved; and thus, the investment of a grid-side alternating-current filter is reduced.

Owner:陈生栋

LED outputting narrow-band notch filtering light and preparation method thereof

ActiveCN102544265BWith filtering effectAdd resonance filter effectDiffraction gratingsSemiconductor devicesGratingWavelength

Owner:苏州东辉光学有限公司

Light-condensing and heat-collecting multistage flash evaporation process device based on feedback control

ActiveCN102701305BIncrease the concentration ratioImprove utilization efficiencyGeneral water supply conservationSeawater treatmentThermal energyConjugated heat transfer

The invention discloses a light-condensing and heat-collecting multistage flash evaporation process device based on feedback control. How to overcome the characteristic that a solar heat source is instable is not considered in the prior art. The light-condensing and heat-collecting multistage flash evaporation process device comprises a solar heat-collecting system, a heat transfer system, a seawater desalting system, a feedback control system and a heat exchanger; the heat transfer system constructs a closed heat transfer working medium circulating loop; the closed heat transfer working medium circulating loop allows a heat conducting working medium to repeatedly circulate; and a seawater desalting loop formed by the seawater desalting system is in an open structure and allows the seawater desalting system to continuously generate fresh water. Meanwhile, a feedback control loop is applied to the light-condensing and heat-collecting multistage flash evaporation process device disclosed by the invention; a flow temperature meter is used for measuring fluid and temperature signals in several pipelines and feeding back the signals to an industrial controller; and according to the feedback signals, the industrial controller generates a control command for adjusting the rotating speeds of each motor and each centrifugal pump. According to the light-condensing and heat-collecting multistage flash evaporation process device disclosed by the invention, adverse influence generated by solar fluctuation is overcome; and meanwhile, the utilization efficiency of heat energy is increased and energy saving and environment friendliness are realized.

Owner:HANGZHOU DIANZI UNIV

Preparation method for embedded composite fibers with excellent cooling and filtering effects and product

PendingCN112795994AReduce heat absorption and cooling effectWith heat absorption and cooling effectArtificial filaments from viscoseArtificial filaments from cellulose derivativesFiberSpinning

The invention relates to a preparation method for embedded composite fibers with excellent cooling and filtering effects. The method comprises the following steps of firstly, carrying out ball-milling dispersion on existing PLA powder particles until the size of the PLA powder particles is 50-500 meshes; enabling base liquid to be in a stirred state; adding the dispersed PLA powder particles into the base liquid during stirring, and obtaining first mixed liquid until all the PLA powder particles are added; dispersing the first mixed liquid to obtain second mixed liquid; spinning the second mixed liquid to obtain initial fibers, wherein spinning is electrostatic spinning or centrifugal spinning or both electrostatic spinning and centrifugal spinning; and enabling the initial fibers to pass through a thermal drying box to be dried and set, so that the embedded composite fibers with excellent cooling and filtering effects are obtained. According to the design, the preparation difficulty is relatively low, and a product is relatively strong in cooling effect, relatively good in filtering effect and relatively high in environment friendliness.

Owner:WUHAN RED GOLDEN LEAF NEW MATERIAL TECH CO LTD

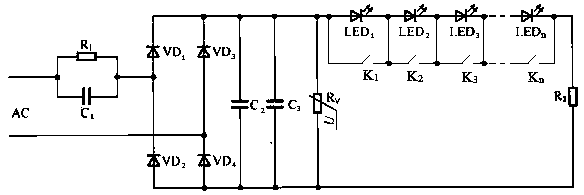

LED drive circuit

InactiveCN107835545ASimple structureWith current limitingElectrical apparatusElectroluminescent light sourcesDriver circuitCurrent limiting

The present invention discloses an LED driver circuit, and the drive circuit is characterized in that the drive circuit comprises a step-down current limiting circuit, a rectifier circuit, a filter circuit, an LED array, and a piezoresistor for protecting an LED from being broken by an instantaneous high voltage. The step-down current limiting circuit comprises a resistor R1 and a capacitor C1. The rectifier circuit comprises rectifier diodes VD1, VD2, VD3 and VD4. The filter circuit comprises capacitors C2 and C3. The LED array comprises a plurality of LEDs and a plurality of switches K. Thedrive circuit is advantageous in that the drive circuit is simple in structure, and has the step-down, current-limiting, rectification and filtering functions; the drive circuit can solve a problem that the sudden increase of a voltage of the circuit affects or damages an element because the circuit is provided with the piezoresistor; the LED is in parallel connection with the switches, so the drive circuit can quickly find out a damaged LED.

Owner:黄福芝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com