A blind ditch production equipment and process

A technology of production equipment and blind ditch, which is applied in the field of blind ditch production equipment and technology, can solve problems such as uneven application, low efficiency of manual application, and shedding of geotextiles, and achieve good connection firmness, better filtering effect, and structural strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

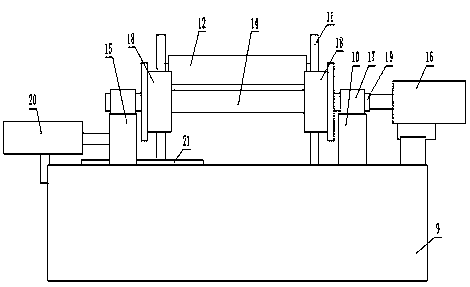

[0039] A blind ditch production equipment, including heat sealing machine, trimming machine, laminating machine and heat cutting machine arranged in sequence;

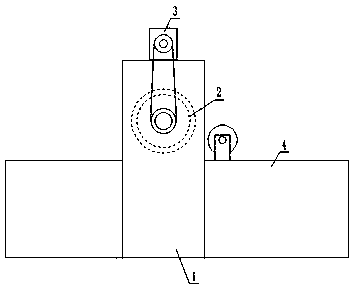

[0040] like figure 1As shown, the heat sealing machine is used to cover the plastic grid and the geotextile to form a composite layer, and the heat sealing machine includes a door-shaped frame 1, a heating roller I2 connected to the door-shaped frame 1 in rotation, a driving heating The motor I3 for roller rotation and the placement platform 4 for placing plastic grids and geotextiles, the motor I3 is installed on the top surface of the gate frame 1, the output shaft of the motor I3 is connected to the driving wheel, and the heating roller I2 The driven wheel is connected on the top, and the driving wheel and the driven wheel are connected by a chain. The placing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com