Curtain type sewage treatment equipment and use method thereof

A kind of sewage treatment equipment, curtain type technology, applied in the field of curtain type sewage treatment equipment, can solve the problems of slow filtration speed, low efficiency, easy to block, etc., and achieve the effect of improving filtration effect, increasing filtration speed, and timely replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

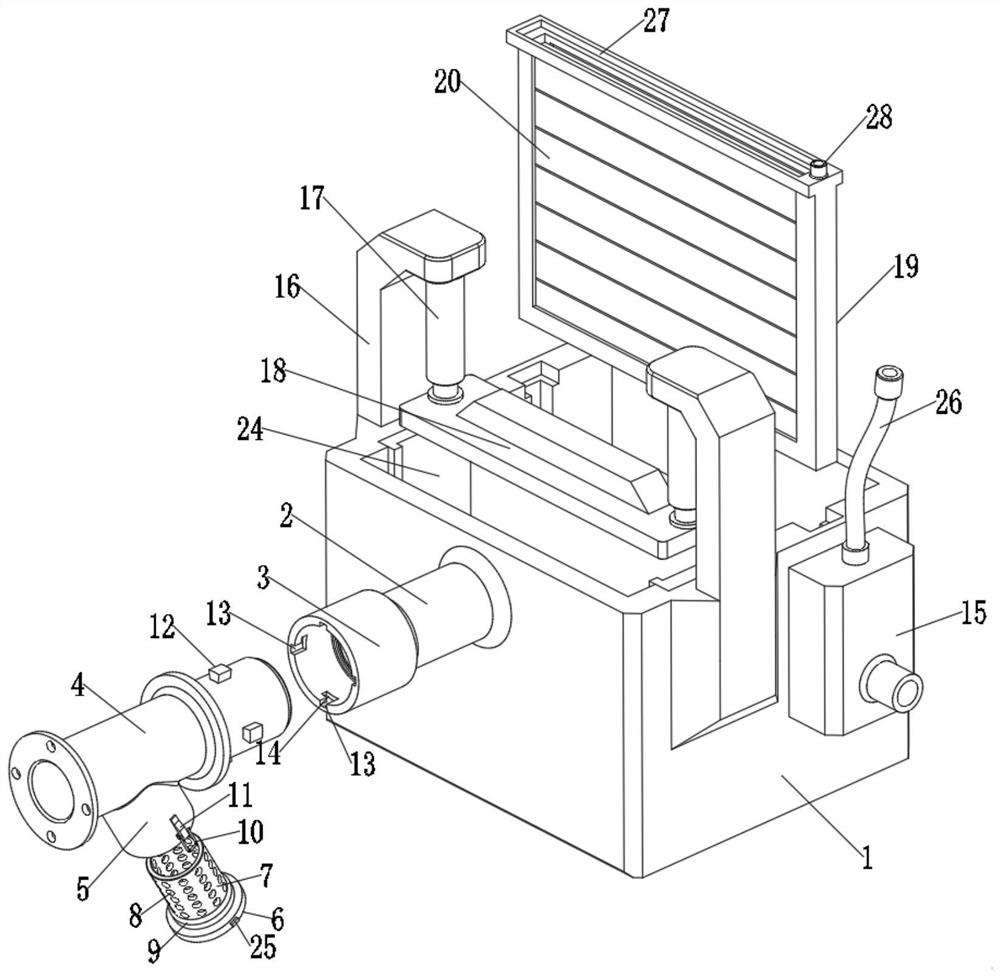

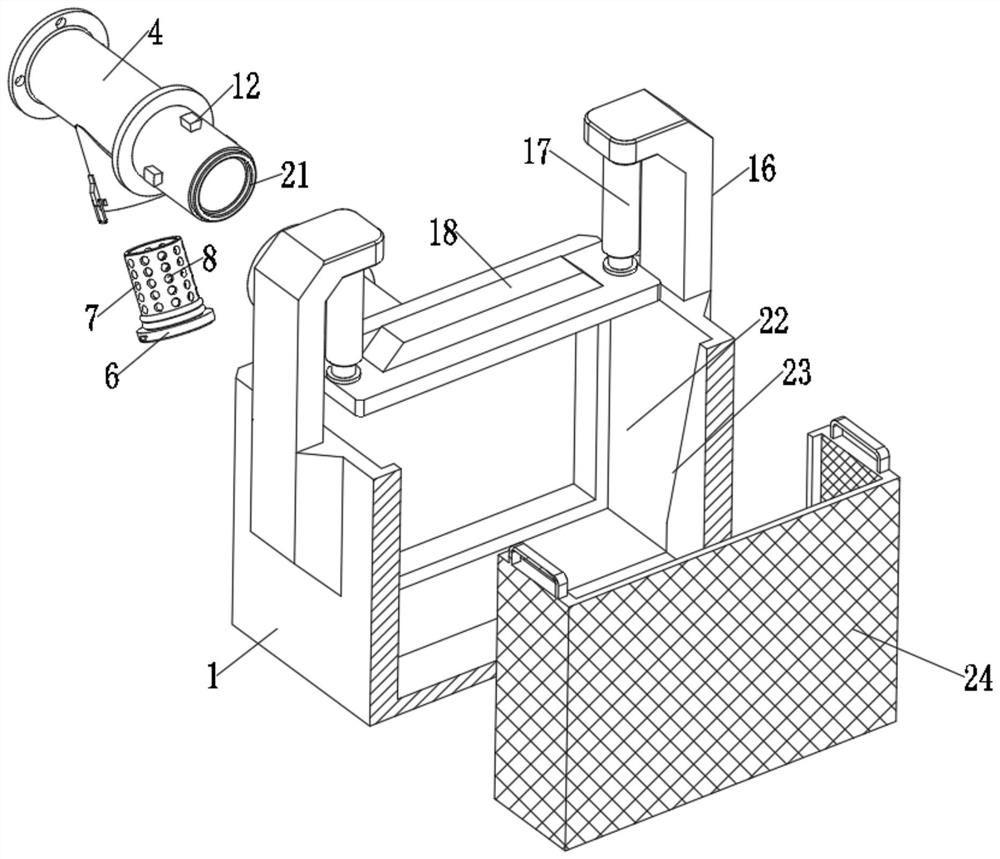

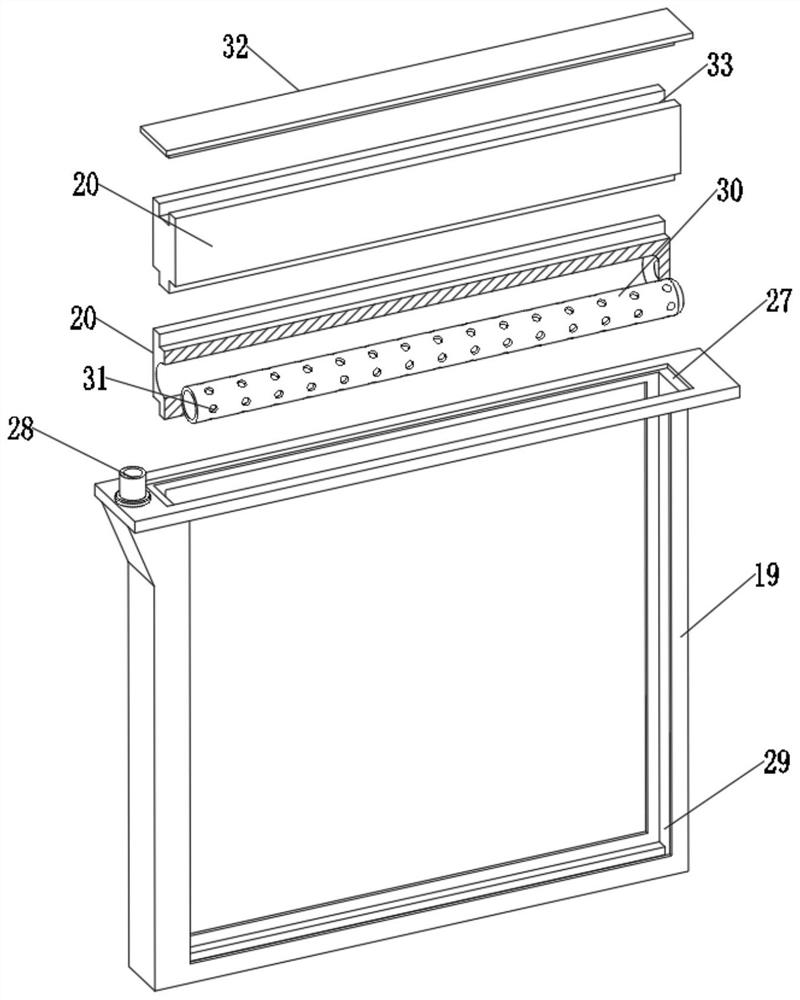

[0032] see Figure 1-5 , and discloses a curtain type sewage treatment equipment, including a box body 1 and a suction vacuum pump 15 on one side of the box body 1, an external hose 26 is installed on the upper end of the suction vacuum pump 15, and a side of the box body 1 is provided with In the liquid inlet pipe 2, the upper end of the box body 1 is symmetrically provided with a support frame 16, a hydraulic shaft 17 is installed on one side of the support frame 16, a pressure plate 18 is installed on the lower ends of the two hydraulic shafts 17, and a filter frame 19 is installed inside the box body 1. , the top of the filter frame 19 is provided with a limit groove 27, the inside of the limit groove 27 is installed with a sealing cover 32, the inside of the filter frame 19 is provided with a limit inner groove 29, and the inside of the limit inner groove 29 is installed with a filter plate 20, One side of the limiting inner groove 29 is provided with a plug port 35, the ...

Embodiment 2

[0035] This embodiment is an improvement made on the basis of Embodiment 1. For details, please refer to Figure 1-5 , a filter press frame 24 is also installed inside the box body 1, and the filter press frame 24 is a mesh structure.

[0036] When in use, the sewage is sent into the tank 1 through the liquid inlet pipe 2, and the sewage is poured into the filter press frame 24 along the direction of the nozzle of the liquid inlet pipe 2, and the filter press frame 24 is located in the tank body 1. When the sewage enters the box body 1, it is pressed down by the pressure plate 18 and pressed into the inside of the filter press frame 24 to squeeze the sewage so that the sewage is pressed into the inside of the filter plate 20. At the same time, when there are impurity particles in the sewage When the filter press frame 24 is used, the filter press frame 24 can be used for filtering, and after a long time of filtration, there will be impurity particles on the bottom surface of t...

Embodiment 3

[0038] This embodiment is an improvement made on the basis of Embodiment 2. For details, please refer to Figure 1-5 The inner wall of the box body 1 is provided with a slot 22 for placing the slot 22 , and a chute 23 is arranged on one side of the slot 22 .

[0039] By placing the card slot 22 and the chute 23, an installation environment can be provided for the filter press frame 24. At the same time, the oblique structure of the chute 23 can ensure that the filter press frame 24 is tilted accordingly when the filter press frame 24 is taken out. Thus, the take-out operation of the filter press frame 24 is facilitated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com