Heavy metal tailing dry discharge system

A technology for heavy metals and tailings, which is applied in the sedimentation tank, the feeding/discharging device of the sedimentation tank, and the separation of sediments by centrifugal force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

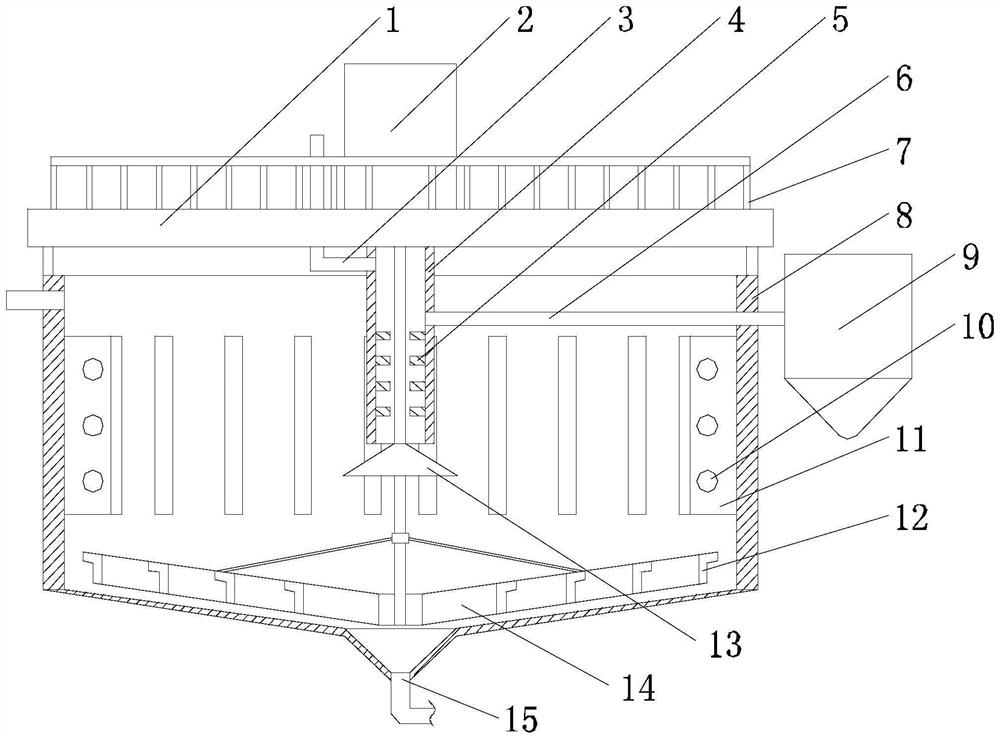

[0030] like Figures 1 to 3 As shown, this embodiment includes a tank body 8 with a tapered bottom, an operating table 1 is erected above the tank body 8, the motor 2 is upside down in the middle of the upper surface of the operating table 1, and the output end of the motor 2 is connected with a rotating shaft, The rotating shaft runs through the operation table 1 and extends to the bottom of the tank body 8 , and a rake arm 12 is arranged on the extension of the rotating shaft, an outer pipe 15 is arranged at the bottom of the tank body 8 , and a sleeve 4 is arranged at the bottom of the operation table 1 . , the sleeve 4 is sleeved on the upper section of the rotating shaft, the liquid outlet end of the cyclone 9 is communicated with the inner upper section of the sleeve 4 through the grouting pipe 6, and the operating table 1 is also provided with a liquid injection pipe that communicates with the inner upper section of the sleeve 4 3. A frustum 13 is provided on the outer ...

Embodiment 2

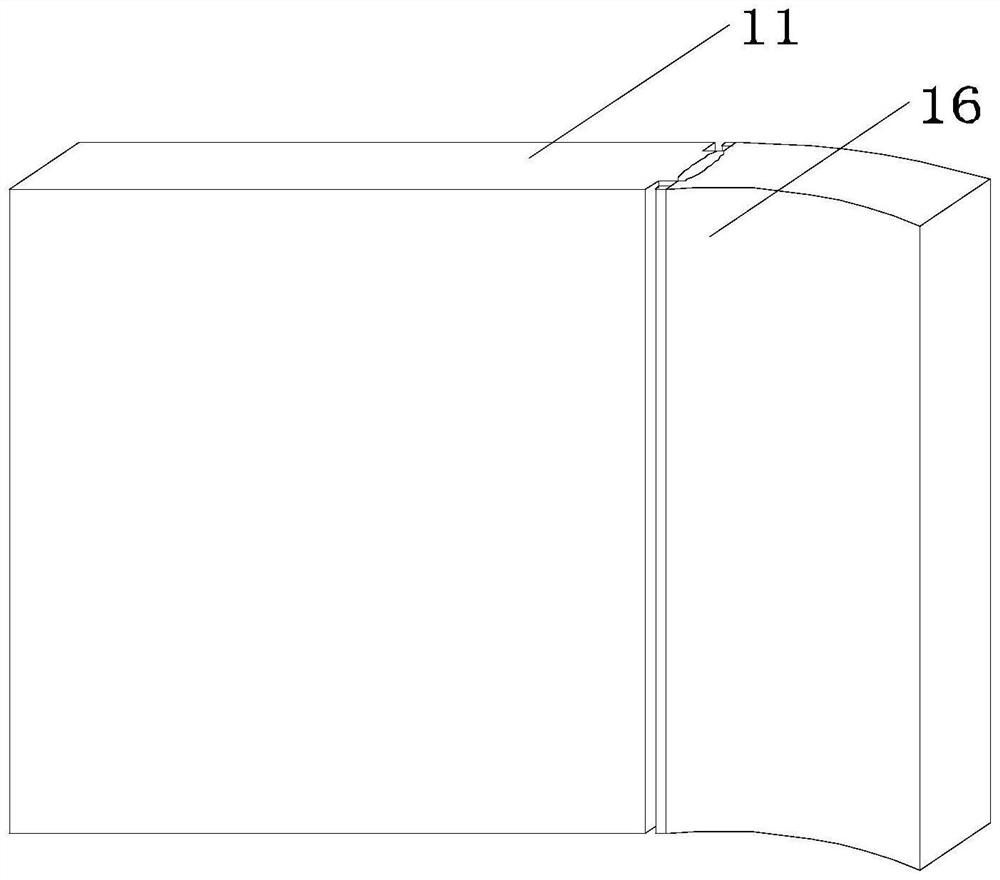

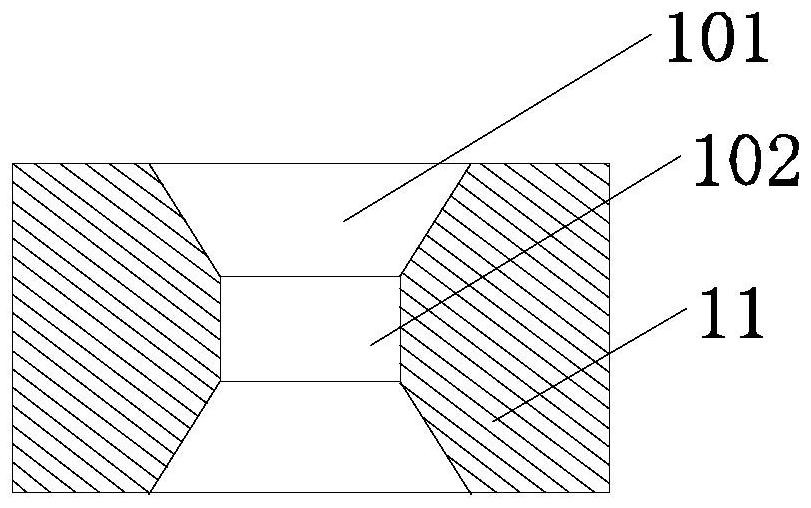

[0035] like Figures 1 to 3 As shown, this embodiment is based on Embodiment 1, and each of the baffles 11 is provided with a plurality of guide holes 10 , and the axis of the guide holes 10 is connected to the sleeve 4 . axis is vertical. The diversion hole 10 includes a through hole 102 and two expansion holes 101 communicating with both ends of the through hole 102 , and the inner diameter of the expansion holes 101 increases from the middle of the through hole 102 toward the side wall of the partition plate 11 .

[0036] When the rake arm 12 agitates the muddy layer at the bottom of the tank 8, the ore slurry above the muddy layer will generate a certain degree of eddy current. There is still a certain fluctuation in the area between the partitions 11. For this reason, in this technical solution, each partition 11 is provided with a plurality of diversion holes 10, so that the two adjacent buffer areas are partially connected, and Since the movement of the pulp in differ...

Embodiment 3

[0040] like Figures 1 to 3 As shown, this embodiment is based on Embodiment 1. In this embodiment, a plurality of annular plates 5 are arranged at intervals from top to bottom on the inner circumferential wall of the sleeve 4 along the axial direction of the sleeve 4, and the annular plates The inner diameter of 5 is larger than the diameter of the rotating shaft, and the grouting pipe 6 and the liquid injection pipe 3 are both located above the annular plate 5 . After the newly fed ore pulp is fed into the sleeve 4, a circulating flow is formed under the action of a plurality of annular plates 5, and after moving to the bottom of the sleeve 4, it contacts with the outer wall of the frustum 13, which also makes the ore pulp and the flocculant fully mixed, forcing The slurry spreads around in the horizontal direction to avoid impacting the sediment layer.

[0041] Preferably, an inner thread cylinder 14 that is threadedly matched is provided on the outer wall of the lower sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com