Sewage treatment plant aerated grit system control apparatus and control method thereof

A sewage treatment plant, aeration and grit deposition technology, applied in the direction of flocculation/sedimentation water/sewage treatment, separation methods, chemical instruments and methods, etc., can solve problems such as inoperability, uneven sedimentation, sand deposition, etc., to avoid excessive operation, improve the treatment effect, avoid the effect of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

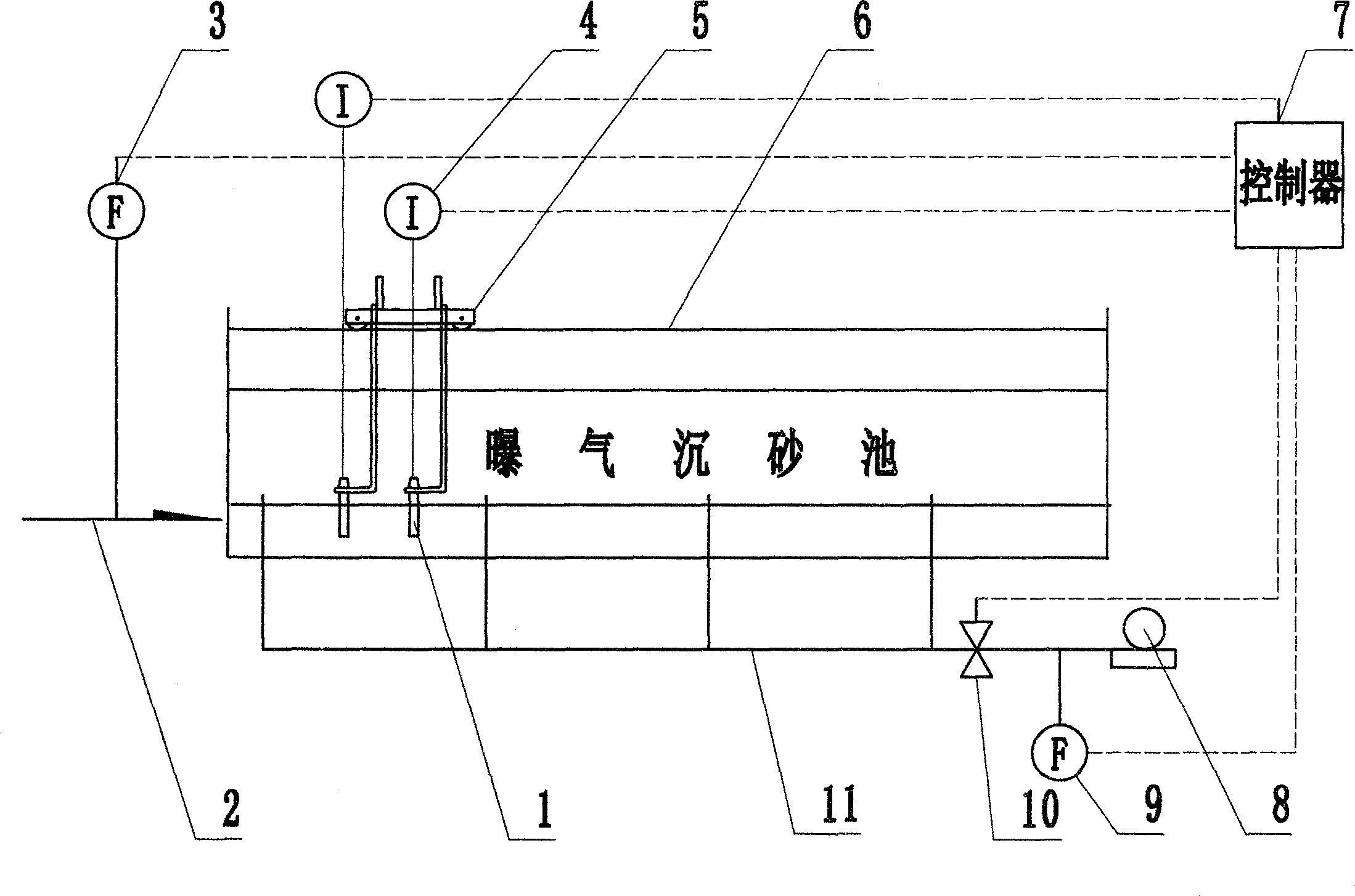

[0020] Embodiment 1: Referring to the accompanying drawings, the control device of the aeration sand settling system of the sewage treatment plant is provided with an aeration sand settling tank 6, and the water inlet pipe 2 in front of the aeration sand settling tank is connected to the sewage water inlet pump room of the sewage treatment plant, and the back The outlet pipe is connected to the primary sedimentation tank or biological reaction tank of the sewage treatment device; the bottom of the aeration grit chamber is provided with an aeration head connected with the blower, the bottom of the tank under the aeration head is provided with a sand collecting tank, and the aeration grit chamber is located in the middle. There is a movable trolley 5, and the movable truss is equipped with two sand pumps 1, which are characterized in that: a controllable electric valve 10 and a gas flow meter 9 are arranged on the pipeline connecting the aeration head and the blower 8; A current ...

Embodiment 2

[0021] Embodiment 2: the control method of the control device of the aeration and sedimentation system of the sewage treatment plant:

[0022] 1) Start the control device, set the gas-water ratio as GWRSET as 0.3, and the valve maximum flow VFMAX as 4m 3 / s, the maximum comparison difference of intake air volume is GMAX 0.4, the comparison interval time T1 is 20 minutes, T2 is 30 minutes, and the maximum flow rate of water intake WINMAX is 10m 3 / s, the operating time base M of the trolley is 60 minutes, the maximum current I of the sand pump in normal operation is 8A, and the maximum operating current IMAX of the sand pump under high load is 11A;

[0023] 2) When the control device runs for a comparison time T1=20 minutes, the controller collects the current influent flow signal WIN1=8m 3 / s, intake air flow signal GIN1=2m 3 / s; Calculate valve opening L=WIN*GWRSET / VFMAX=60%, load factor N=WIN / WINMAX=0.8, crane running time T3=N*M=48 minutes

[0024] 3) WIN1*GWRSET-GIN1=8*...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com