Manufacturing method of special cast gold club head and shell mold thereof

A golf club head and manufacturing method technology, applied in the direction of rotors, cylinders, heat exchange equipment, etc., can solve problems such as unsatisfactory molding yield of castings, increased melting difficulty, difficulty in reducing casting costs, etc., to achieve improved molding yield Effects on quality, improvement of bonding stability, and reduction of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

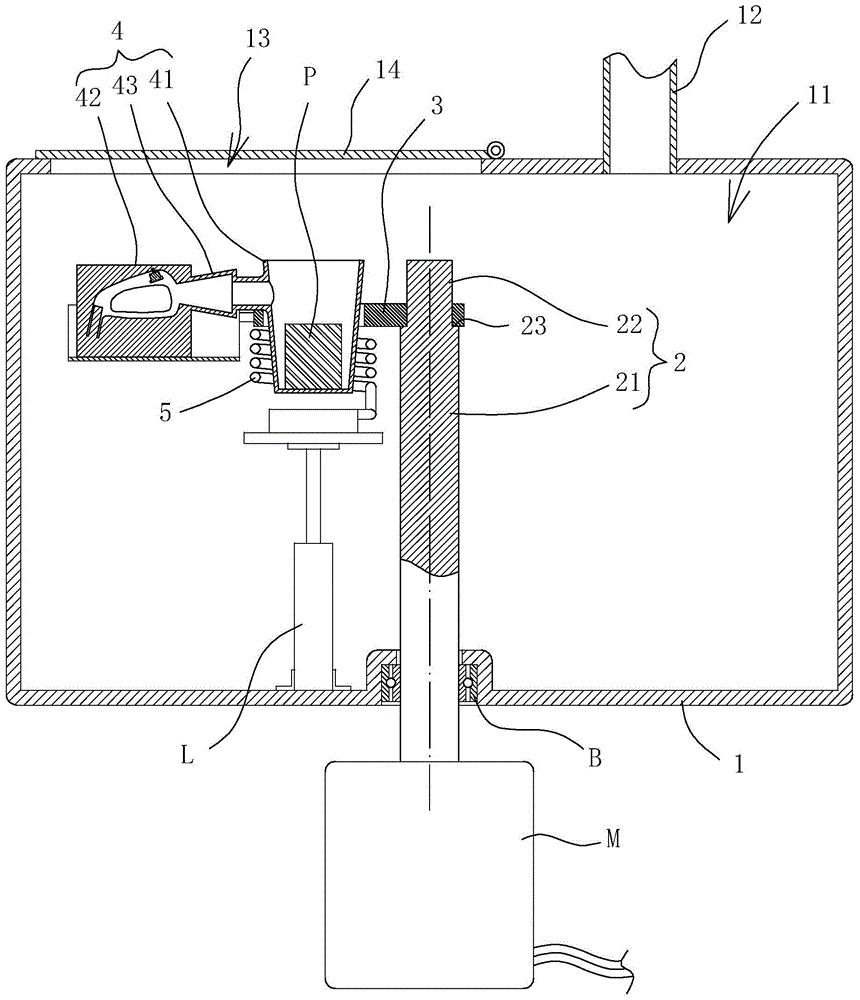

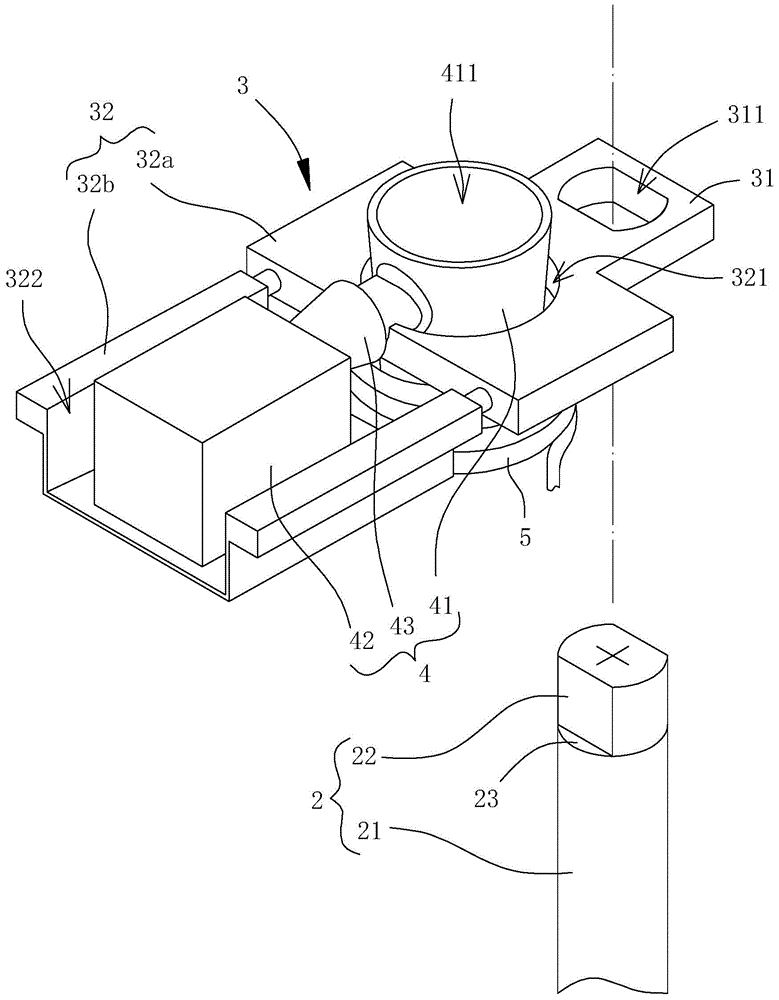

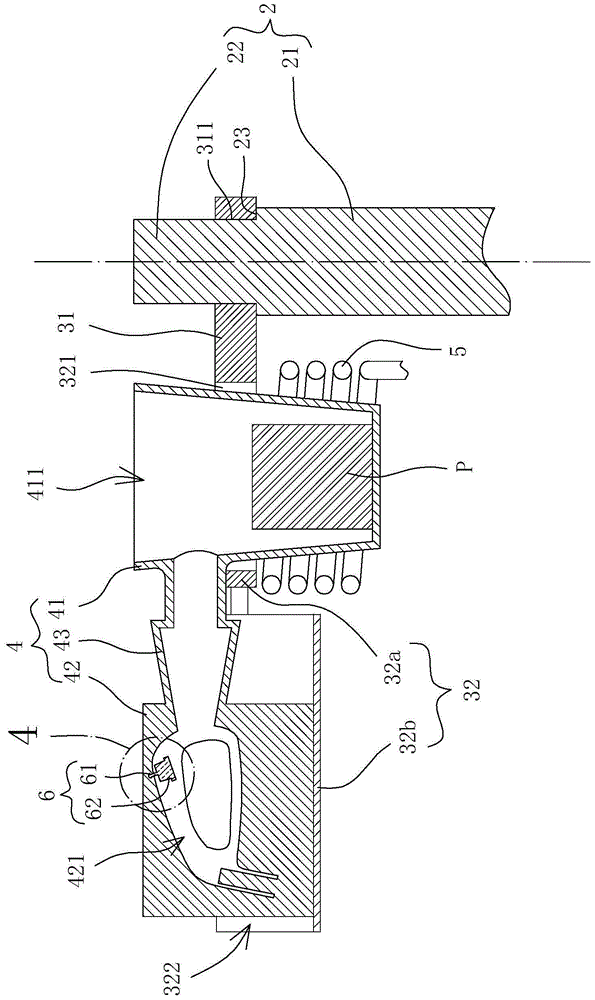

[0056] Please refer to figure 1 , is a vacuum centrifugal casting device used in conjunction with the golf club head manufacturing method of casting and cladding different materials of the present invention. Wherein, the vacuum centrifugal casting device comprises a vacuum furnace 1, a rotating shaft 2, a rotating platform 3, a shell mold 4 and a heater 5; the rotating shaft 2, the rotating platform 3, the shell mold 4 and the heater 5 are all located on In the vacuum furnace 1 , the rotating platform 3 is connected to the rotating shaft 2 to rotate synchronously with the rotating shaft 2 , the shell mold 4 is positioned on the rotating platform 3 , and the heater 5 is used to heat the shell mold 4 .

[0057] Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com