Mechanism capable of adjusting thickness of pencil lead tip for pencil sharpener and pencil sharpener

A technology for pencil sharpeners and pencil cores, applied in sharpening devices, printing, office supplies, etc., can solve problems such as broken cores and wood chip blockage, increase production costs, and affect the normal operation of pencil sharpeners, etc., to improve cutting reliability , to avoid the effect of broken core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

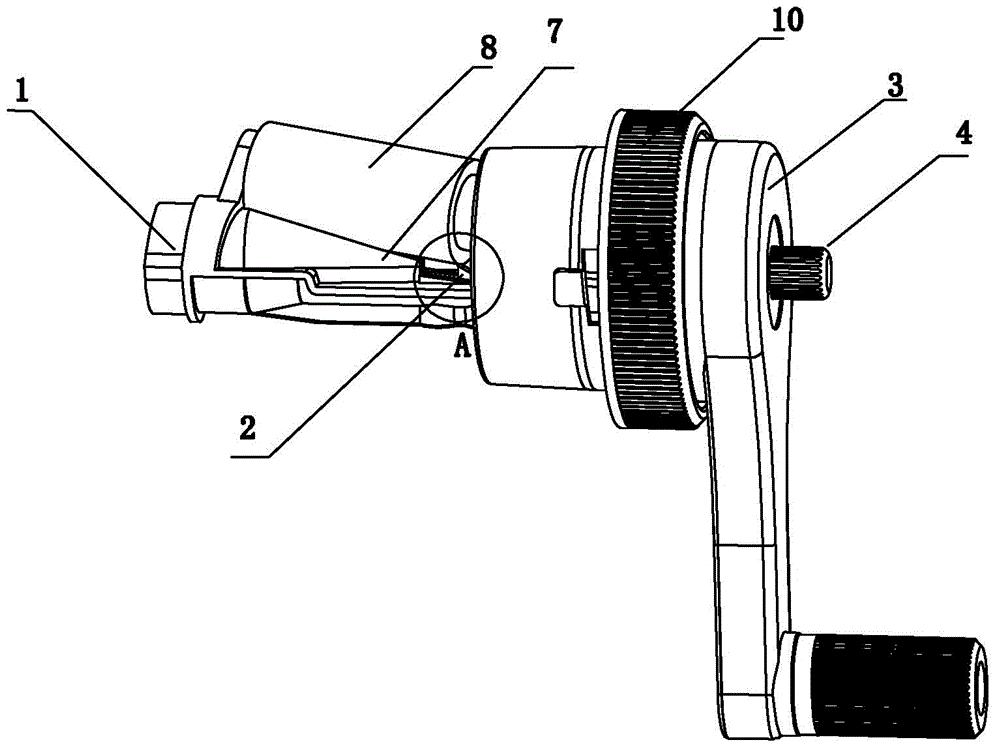

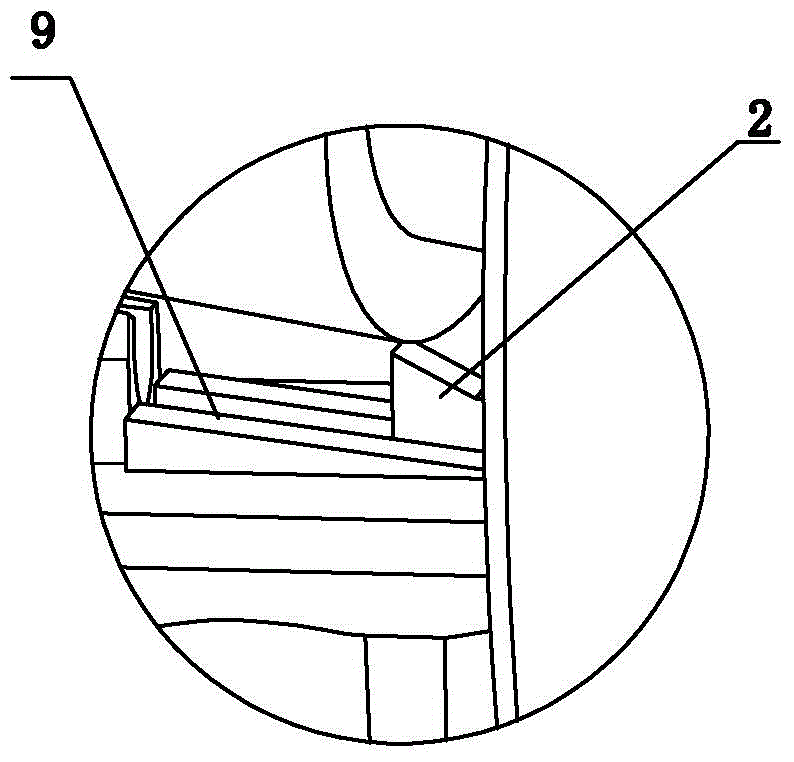

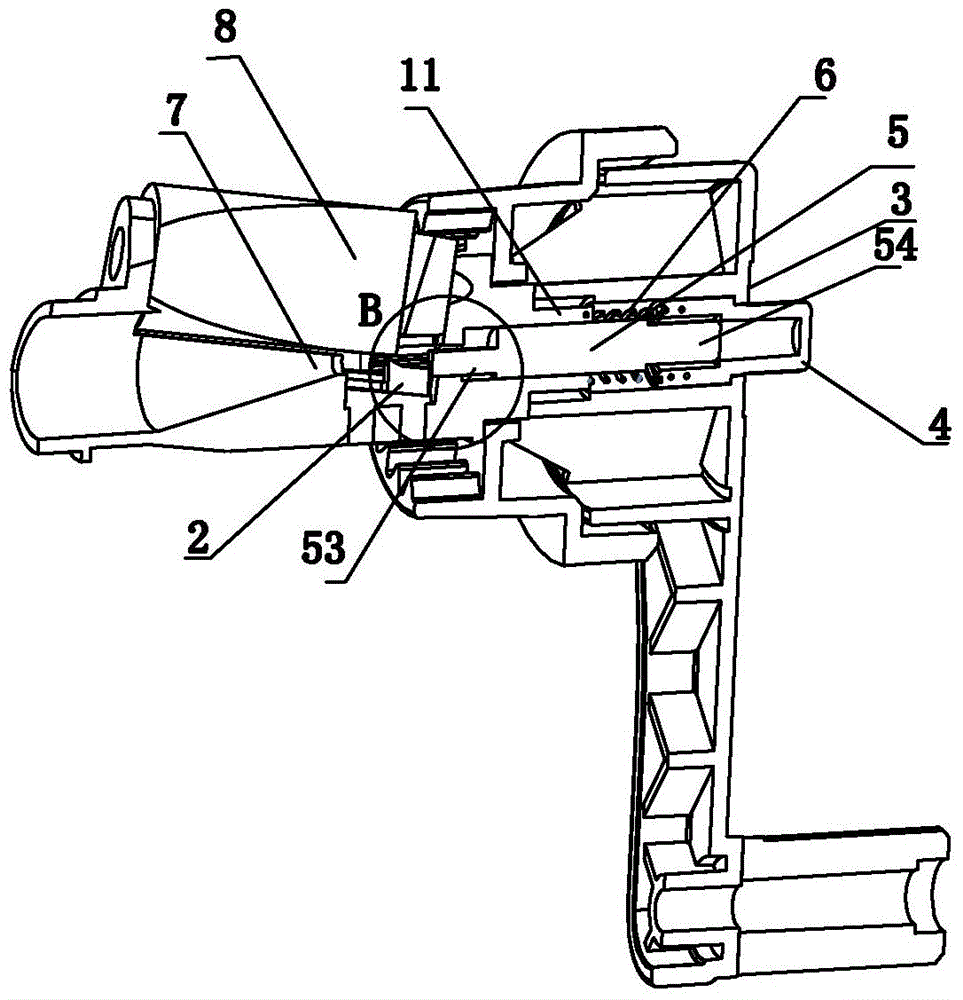

[0020] Examples, combined with figure 1 , figure 2 , image 3 As shown, a mechanism for adjusting the thickness of the pencil lead point on a pencil sharpener includes a sliding stop 2 independently arranged on the tool holder 1, a rotation button 4 installed on the rocker arm 3, and one end of which is passed through the tool holder 1 and The telescopic rod 5 that can move axially in the knife holder 1, the other end of the telescopic rod 5 is connected to the rotary button 4 through a thread, the telescopic rod 5 is covered with a spring 6, and the spring 6 is pressed against the inner side of the rotary button 4 and the end of the tool holder Between 11; Turn the rotary knob 4, the telescopic rod 5 moves forward slowly to push the sliding stop block 2 to the pen entry hole 7; press the rotation button 4 inward, the telescopic rod 5 moves forward quickly and push the sliding stop block 2 to the pen entry hole 7.

[0021] Such as image 3 , Figure 4 As shown; the tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com