Double-hull bottom double-hull ship

A double-hull and ship-bottom technology, which is applied in the field of ships, can solve the problems of high maintenance costs, heat resistance, and high maintenance costs, and achieve the effects of ensuring the safety of life and property, increasing safety, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

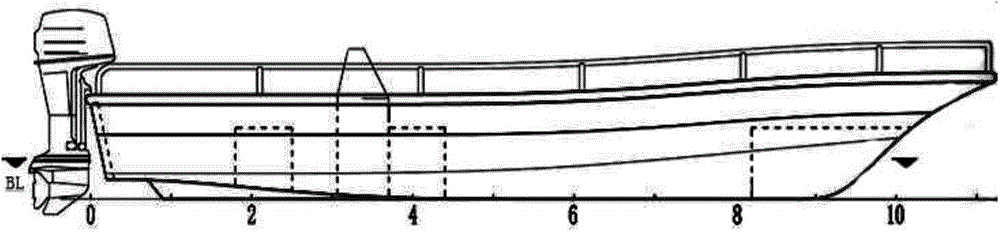

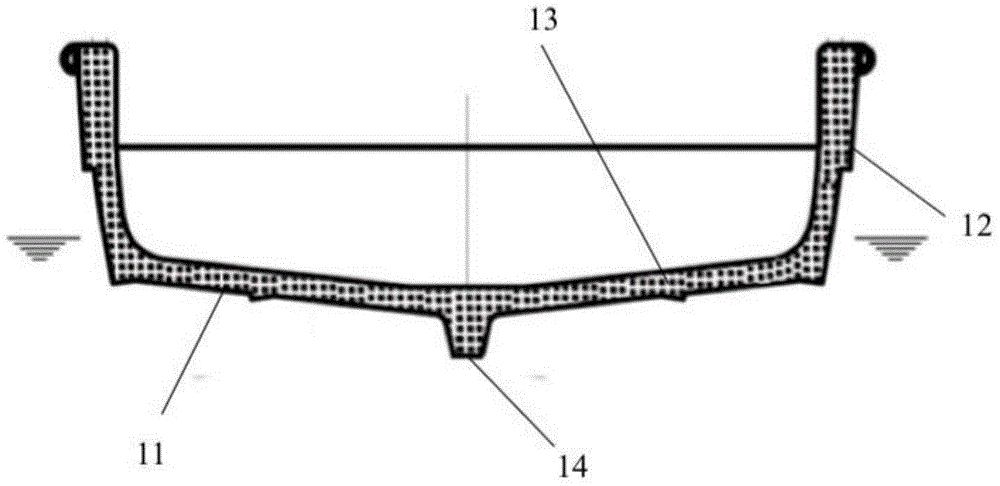

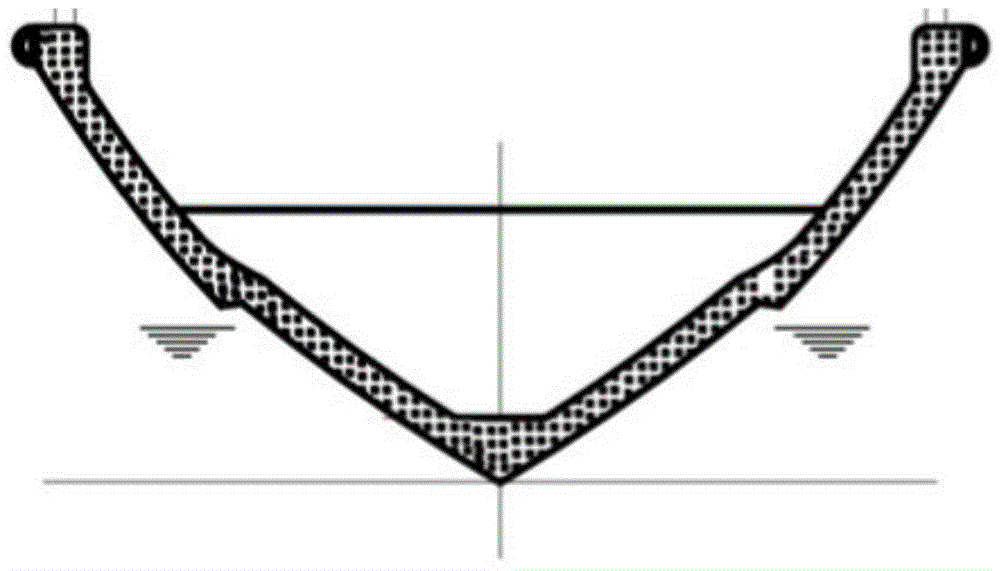

[0023] combine Figure 1-4 , the present invention is described in detail, and the present invention provides a double-bottom double-hull ship, which includes a double-layer ship bottom 11 and a double-layer ship hull 12, and a foam layer 13 is arranged between the double-layer ship bottom gaps. It should be noted that, here, the bottom of the ship and the hull are relative terms, the bottom of the ship refers to the bottom of the hull itself, and the hull refers to the side of the hull itself, the double-sided side. The foam layer is formed by foaming a foam material. Foaming materials and foaming technology are relatively mature technologies, widely used in various fields, and will not be described here. Foaming materials can be polyurethane (PU), polyethylene (PE), polyvinyl chloride (PVC), ethylene / propylene copolymer (EVA), polyethylene terephthalate (PET), styrene-butadiene rubber (SBR), One or more of neoprene (CR), natural rubber (NR), polystyrene (EPS).

[0024] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com