Real-time yield predicting method for catalytic cracking device

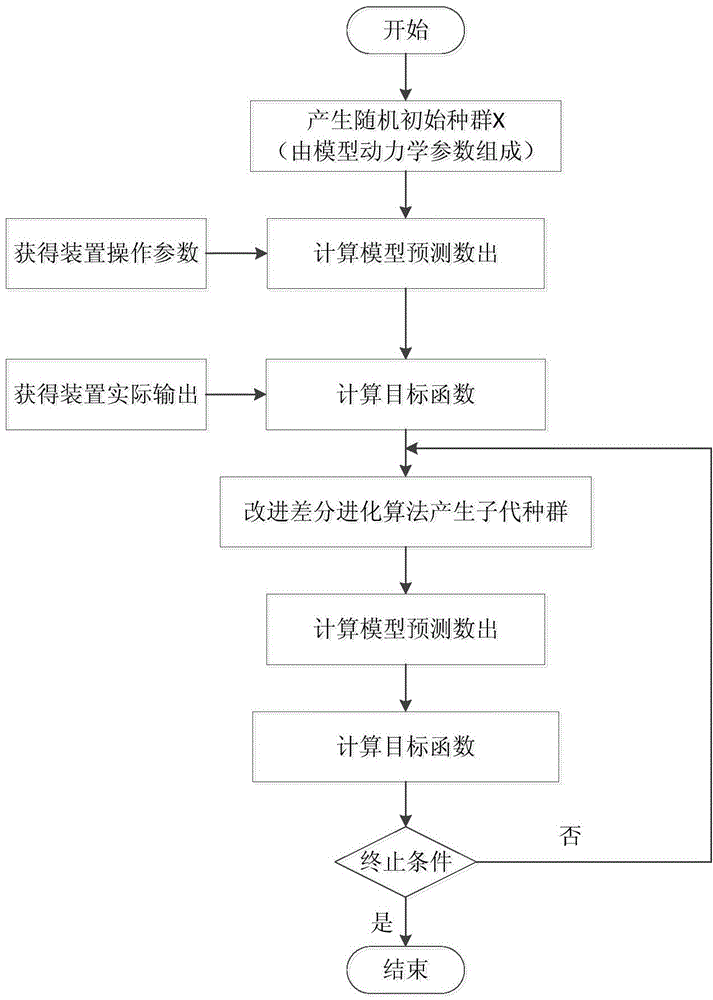

A catalytic cracking device, real-time prediction technology, applied in the direction of catalytic cracking, cracking, petroleum industry, etc., can solve the problem that it is difficult to accurately describe the operation process of the device, achieve the effect of continuous real-time prediction and increase the calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

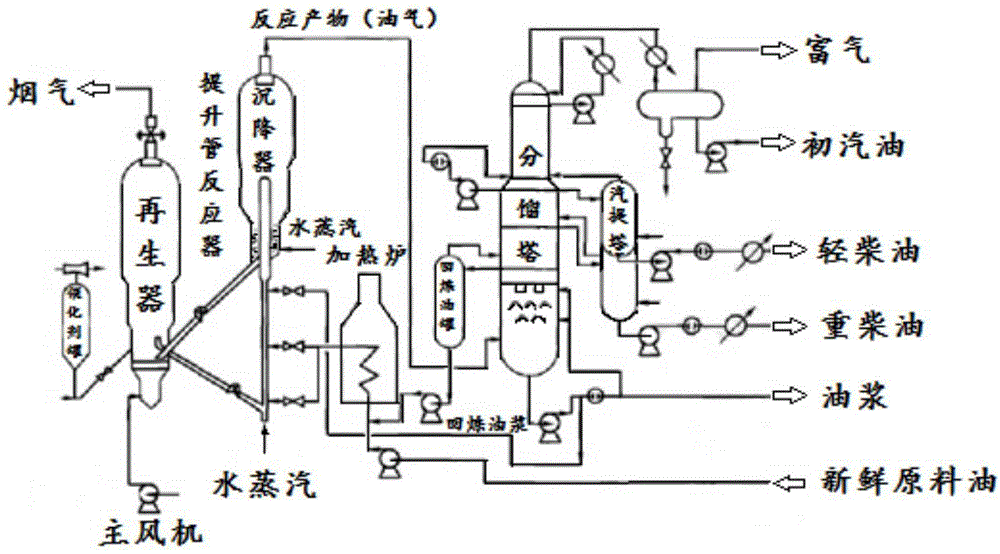

[0034] 1. Mechanism modeling of catalytic cracking

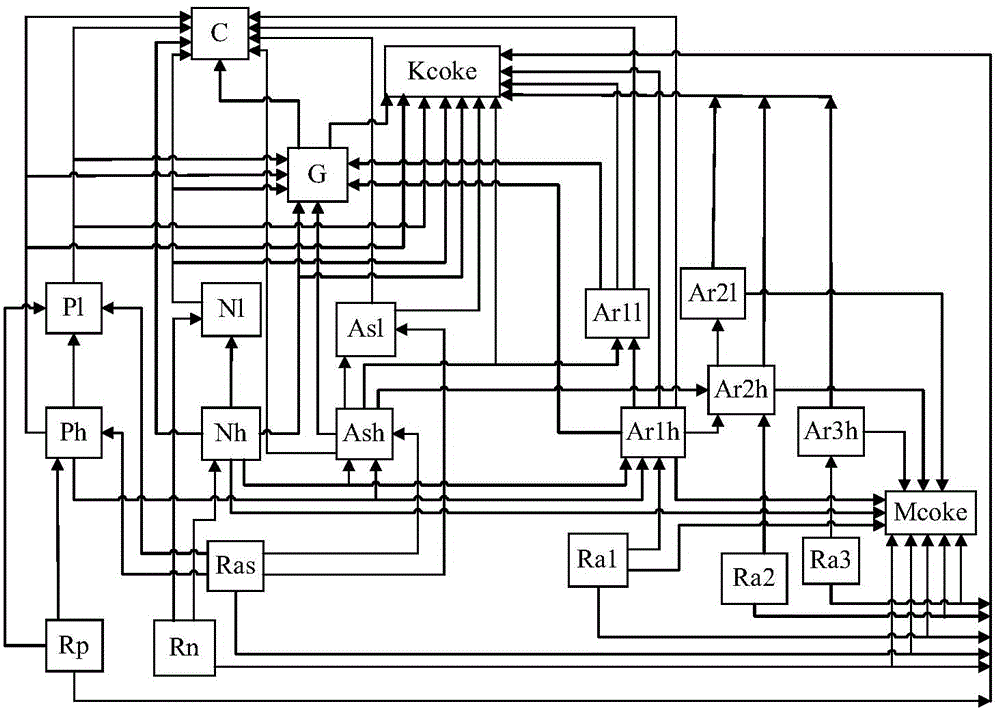

[0035] The raw material of the catalytic cracking process is heavy oil, and the catalytic cracking reaction involves many components and a complex reaction system. Catalytic cracking raw materials mainly contain alkanes, naphthenes, aromatics and a small amount of olefins. A large number of studies have shown that under catalytic cracking conditions, the reactions that occur in catalytic cracking mainly include: decomposition reactions of alkanes, decomposition reactions of olefins, isomerization reactions, hydrogen transfer reactions, aromatization reactions, decomposition reactions of cycloalkanes, hydrogen Transfer reaction, isomerization reaction, ring-opening cracking reaction and condensation reaction of aromatics. For the modeling of reaction kinetics of such a complex reaction system, a lumped kinetic model is required. The so-called lumping (Lumping) is to merge all kinds of molecules in the complex reaction syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com