Flood drainage system sealing structure with the function of draining underground spring water and tailings seepage

A technology for tailings and functions, applied in the field of plugging structures of tailings pond flood discharge systems, can solve problems such as large engineering volume, uncompact grouting, and low fluidity, and achieve small construction engineering volume, avoid seepage damage, and sand discharge. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

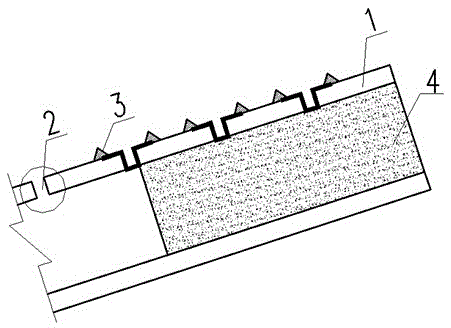

[0028] This embodiment includes an upstream blocking structure and a downstream blocking structure, refer to figure 1 , the upstream sealing structure includes a chute 1, a gap 2 is left between the cover plates of the chute 1, and non-woven geotextile I is filled in the gap 2, and the edge of the non-woven geotextile I extends to the cover plate of the chute 1, without The length of the woven geotextile I extending to the cover plate of the chute 1 is 30 cm, and the extended edge of the non-woven geotextile I is poured with cement mortar 3, and the extended edge of the non-woven geotextile I is fixed on the chute 1 through the cement mortar 3 The cover plate; the entrance section of the chute 1 is provided with a concrete block 4, and the specification of the non-woven geotextile I is 400g / m 2 .

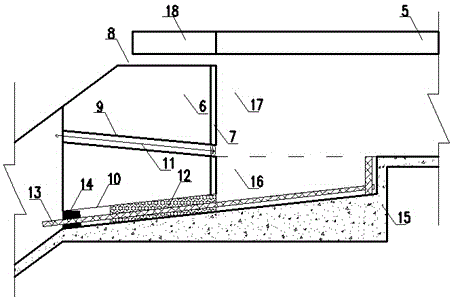

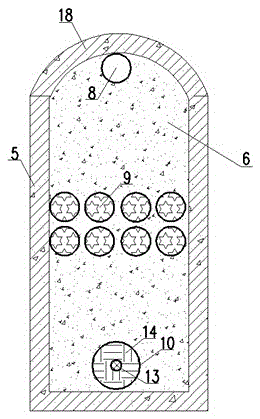

[0029] refer to figure 2 , ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com