Structure of centrifugal fan impeller

A centrifugal fan and impeller technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low production efficiency, high cost, complex processing technology, etc., and achieve the effect of improving performance and increasing filtration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

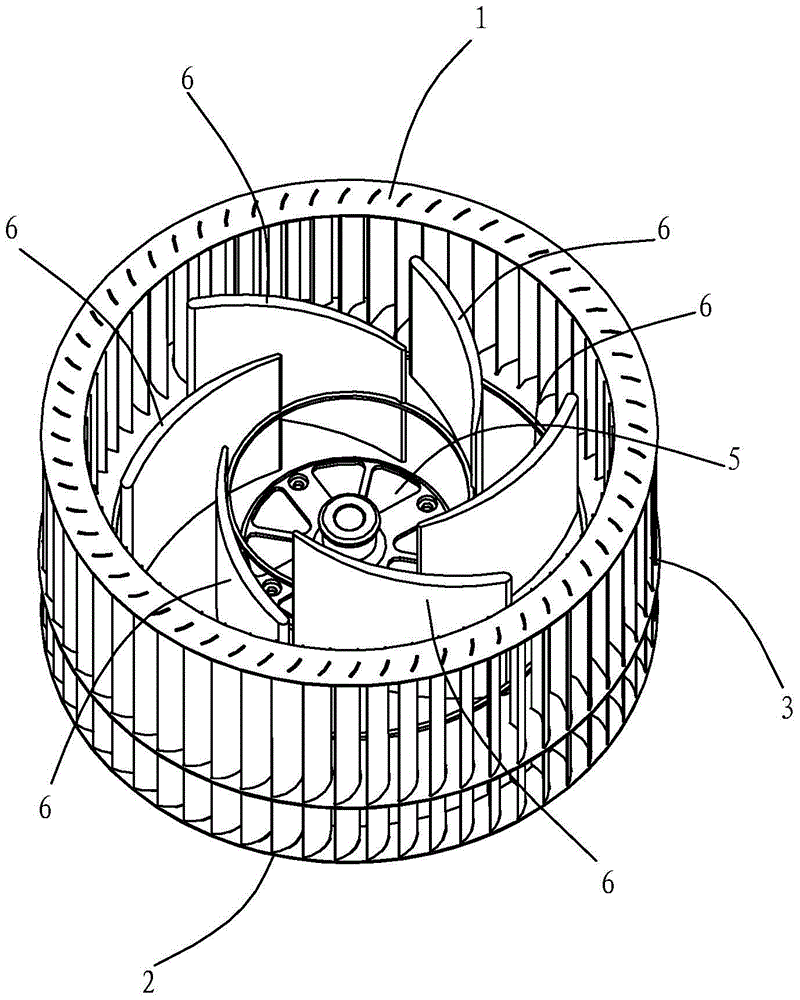

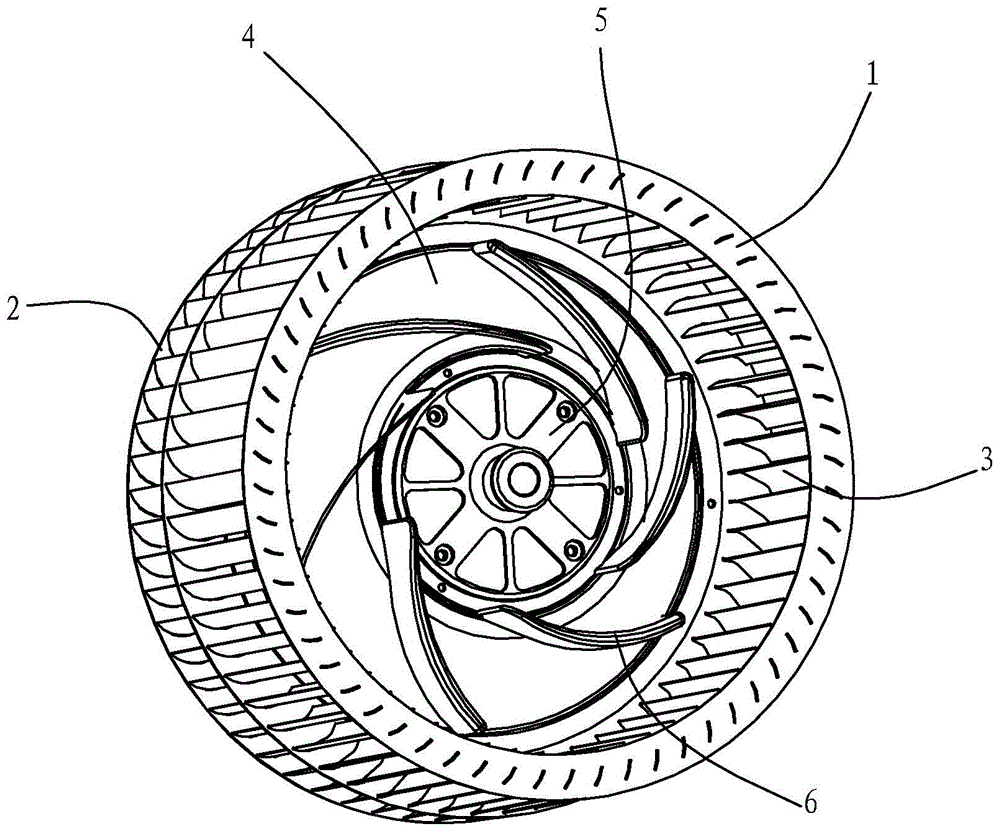

[0022] Such as figure 1 and figure 2 Shown is the centrifugal fan impeller structure in Embodiment 1 of the present invention, which has a front ring 1 and a rear ring 2, 60 blades 3 are fixed between the front ring 1 and the rear ring 2, and the outer ring blades 3 and the front ring 1 And the rear ring 2 is all fixed together by existing conventional riveting methods. A middle disc 4 is also arranged between the front ring 1 and the rear ring 2, and the center of the middle disc 4 is fixed with a wheel disc 5 for installing a motor by a rivet. The outer edge of the middle plate 4 is provided with a blade slot 42a corresponding to the blade. The blade 3 passes through the blade slot of the middle plate 4 and the blade 3 is stuck in the blade slot through the deformation of the blade slot, thereby realizing the blade slot. 3 and the fixation of the middle plate 4. The deformation of the blade slot is achieved by rolling the outer ring of the middle disc 4 to be radially st...

Embodiment 2

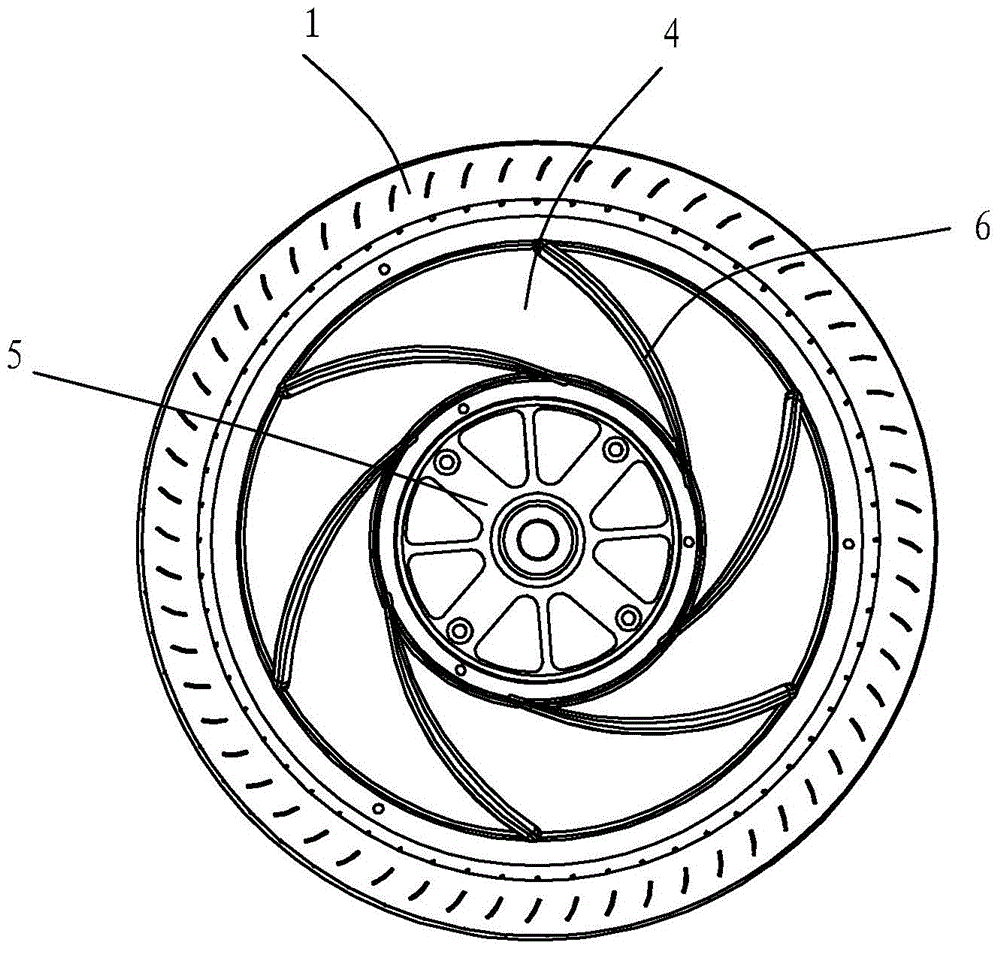

[0027] Different from Embodiment 1, the central disk 4 is in the shape of a flat plate, and the inner ring blades 6 are evenly distributed in a spiral shape in the radial direction of the central disk. see Figure 4 , 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com