Manure preparing device utilizing gear rack adjusting mechanism for adjusting angle and preparing method

An adjustment mechanism, rack and pinion technology, applied in the direction of dryers, drying solid materials, drying gas arrangement, etc., can solve the problems of fertilizer particle deformation, rolling on the inner wall, difficult to remove, etc., to avoid collapse and rolling Distortion, avoid hard-to-remove effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

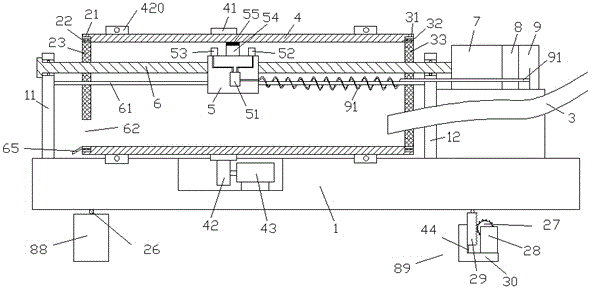

[0017] according to figure 1 The present invention will be described in detail.

[0018] According to an embodiment, a device for fertilizer preparation that utilizes a rack and pinion adjustment mechanism to adjust the angle includes fertilizer granule drying equipment, and the fertilizer granule drying equipment includes: a mounting frame 1 and a bearing 420 that is rotatably mounted on the Install the rotary drying cylinder 4 on the frame 1, the left end of the rotary drying cylinder 4 is provided with a left recess 21, a left bearing part 22 is installed in the left recess 21, and a left bearing part 22 is arranged on the left bearing part 22. There is a left drying cylinder baffle plate 23, the right end of the rotary drying cylinder 4 is provided with a right recessed part 31, a right bearing part 32 is installed in the right recessed part 31, and a right drying part 32 is arranged on the right bearing part 32. Cylinder baffle 33, the bottom of the left drying cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com