Accurate regulation and adhesion device for indication gratings

A technology of indicating grating and bonding, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problem of inaccurate control of the width of Moiré fringes, and achieve avoidance of unnecessary errors, intuitive data timeliness, and strong reference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

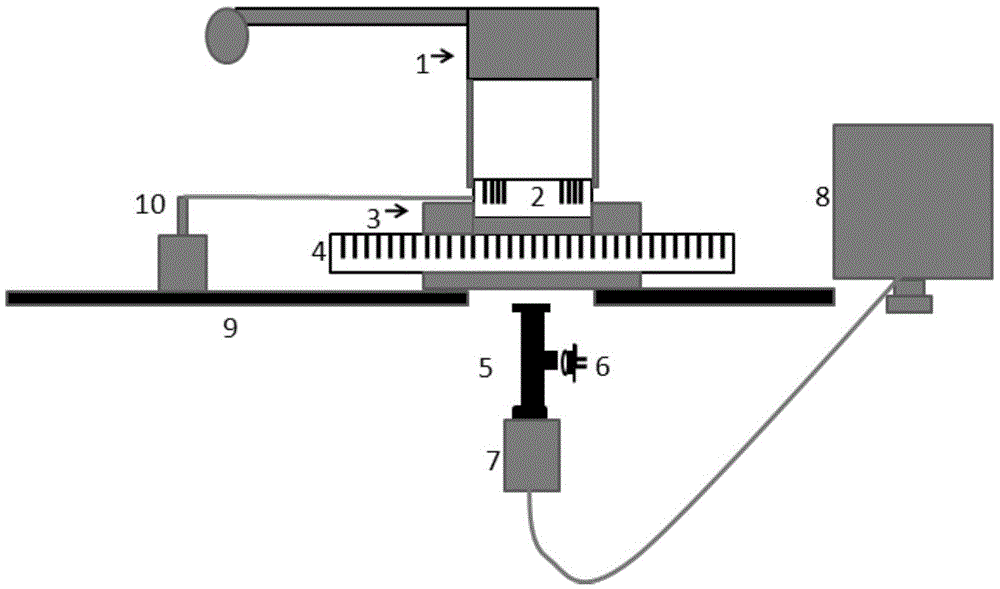

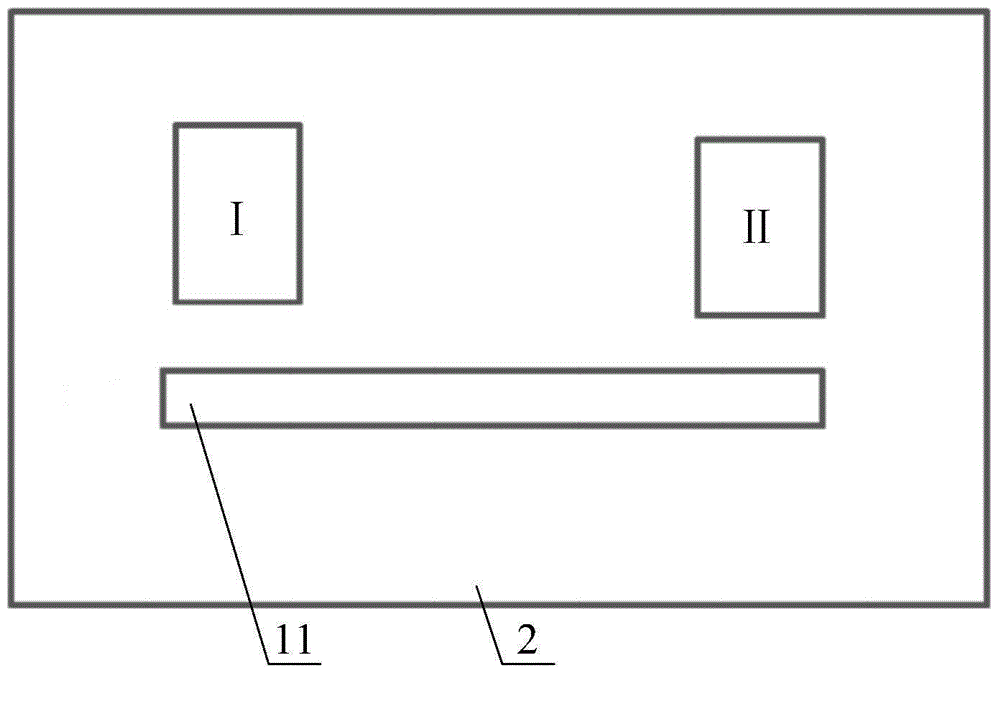

[0022] See attached figure 1 attached figure 2 And attached image 3 , the precise adjustment and bonding device of the indicator grating of the present invention includes a support platform 9, an indicator grating adjustment module 1, an indicator grating 2, a carriage 3, a main grating 4, an illumination source 6, a coaxial optical lens 5, a camera 7, and a computer 8 And automatic dispensing machine 10;

[0023] The main grating 4 is fixed on the support platform 9 through the carriage 3, the indicator grating 2 is arranged above the main grating 4, and is fixed with the indicator grating adjustment module 1, and the computer 8 controls the camera 7 through the coaxial The optical lens 5 images the main grating 4 and the indicating grating 2, illuminates through the illumination light source 6, adjusts the relative position between the indicating grating 2 and the main grating 4 through the indicating grating adjustment module 1, and controls the automatic glue dispenser...

Embodiment 2

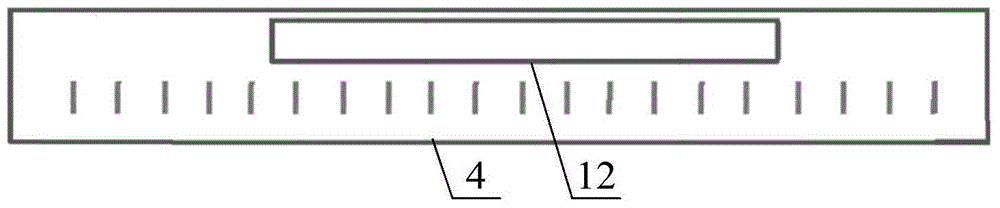

[0037] The difference between this embodiment and Embodiment 1 is: see the attached Figure 6 , the marking pattern on the indicating grating 2 is a horizontal marking pattern, see attached Figure 7 , the marking pattern on the main grating 4 is a plurality of straight lines, the left endpoints of the plurality of straight lines coincide, and are arranged upward at the same angle with a horizontal straight line as the reference.

[0038] The working process of the present invention is as follows: the indicating grating 2 is placed above the main grating 4 through the indicating grating adjustment module 1, and when the light source is illuminated, the indicating grating 2 and the main grating 4 are imaged on the camera 7 through the coaxial optical lens 5, and on the screen The image of the two gratings appears, that is, the Moiré fringe observation window and the marking pattern can be seen. At the same time, the computer 8 displays the angle between the two gratings at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com