Wire break detecting device used for cable stranding equipment

A detection device and equipment technology, applied in the direction of measurement devices, instruments, etc., can solve the problems that the detection board cannot be overlapped, and the broken wire detection of the stranding equipment cannot be effectively applied, so as to reduce the production scrap rate, convenient and flexible installation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The present invention will be further described in conjunction with accompanying drawing and specific embodiment:

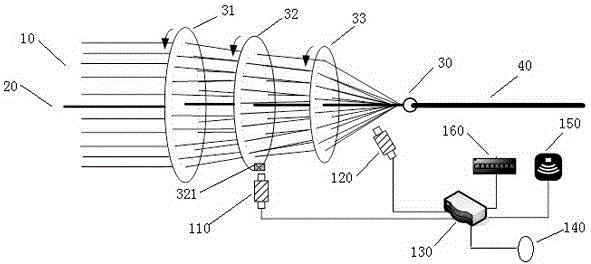

[0023] The schematic diagram of the overall structure of the broken wire detection device of the present invention is as follows: figure 1 As shown, the stranding process of the common stranding equipment is as follows: the iron plate wound with the wire 10 is installed in the cage frame of the stranding equipment, and each strand of wire 10 passes through the cage frame, and then passes through multiple The coaxially rotating rotor parts are wound around the outer layer of the steel core 20 near the stranding opening 30 to form a metal cable 40 .

[0024] The stranding device of this embodiment includes three coaxially rotating rotor parts, a first rotor part 31 , a second rotor part 32 and a third rotor part 33 .

[0025] An induction block 321 is installed on the axial edge of the second rotor part 32 , and a proximity sensor, ie, a rotor indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com