A gas on-site test device for plug-sealed rigid containers

A rigid container and on-site testing technology, which is applied in the field of analysis and testing, can solve problems such as inability to conduct on-site testing and unconnected testing instruments, and achieve the effect of on-site testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

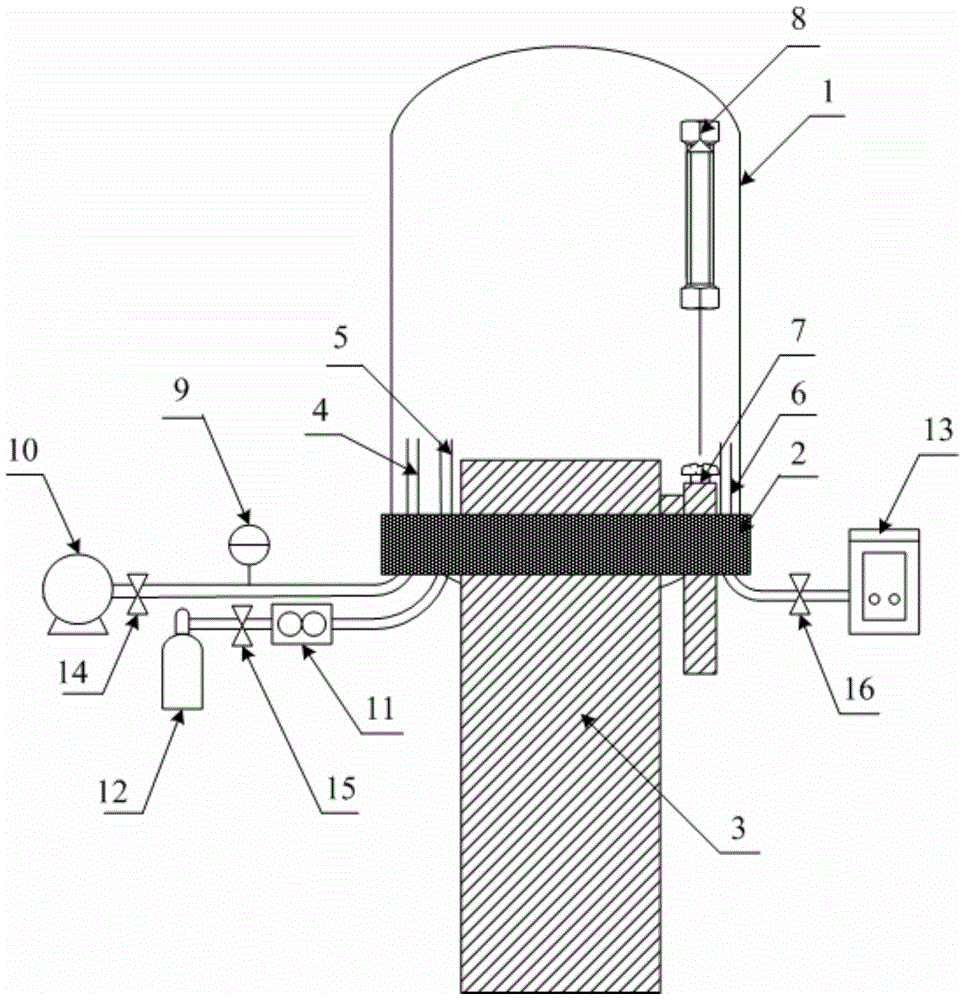

[0011] Such as figure 1 Shown is a schematic structural view of the device of the present invention. The flexible sampling chamber 1 completely wraps the end of the screw plug-sealed rigid container 3 with a built-in screw 8 and introduces three gas conduits, namely the exhaust conduit 4, the intake conduit 5 and the test conduit 6. Wherein, the exhaust conduit 4 is connected to the pressure gauge 9 and the vacuum pump 10, the intake conduit 5 is connected to the argon gas 12 through the flow meter 11, and the test conduit 6 is connected to the gas tester 13, and each conduit has a switching valve. The gap between the sampling chamber 1 and the screw plug-sealed rigid container 3 is filled with sealing mud and sealed with a sealing tape 2 . Open the vacuum pump 10 and the exhaust valve 14 to completely discharge the air in the sampling chamber, and the volume of the sampling chamber is compressed to zero at this time. Close the exhaust valve 14 and the vacuum pump 10, let st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com