Silicon carbide power component

A technology of power components and silicon carbide, applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problem of adding steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Relevant detailed description and technical content of the present invention, now just explain as follows with respect to matching drawing:

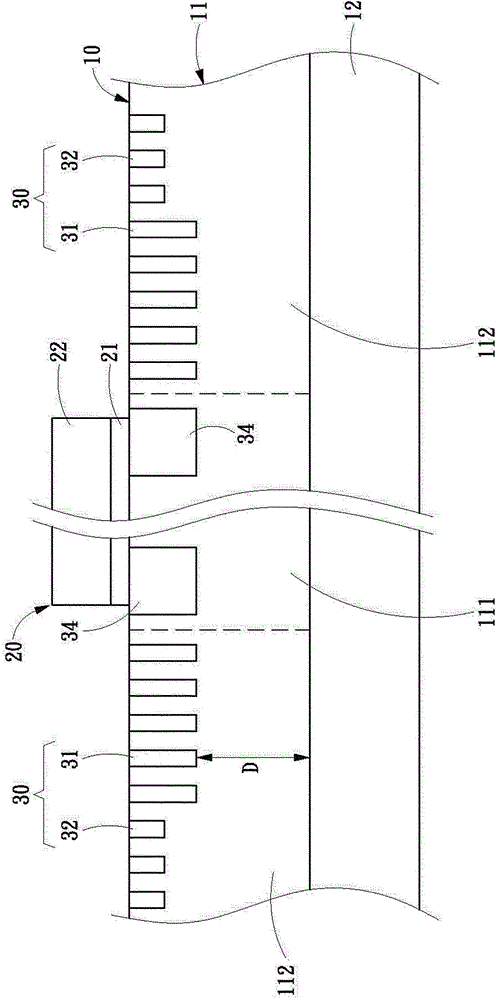

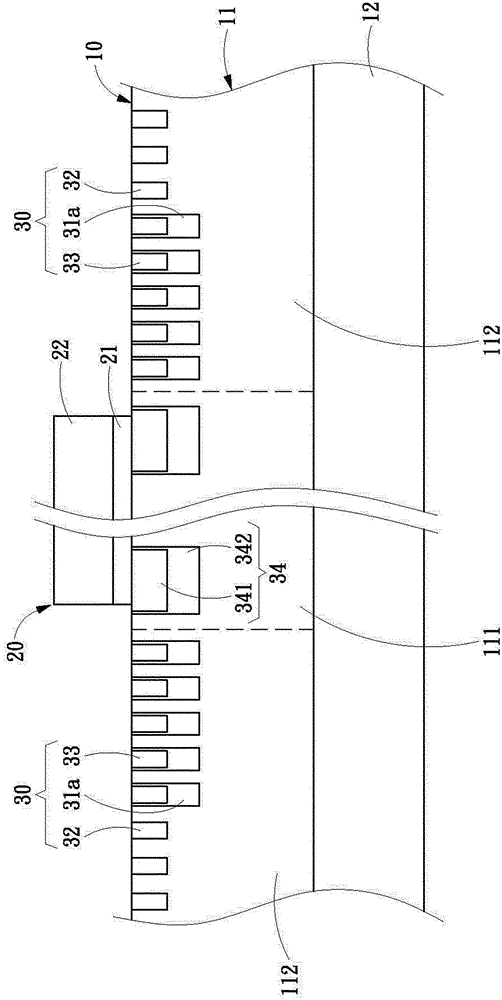

[0016] see figure 1 As shown, it is a schematic structural diagram of the first embodiment of the present invention, as shown in the figure: the present invention provides a silicon carbide power element with a terminal structure, including a silicon carbide substrate 10, a power element structure 20 and a terminal structure 30 . The silicon carbide substrate 10 includes a base layer 12 and a drift layer 11 on the base layer 12. Both the base layer 12 and the drift layer 11 have a first conductivity. In this embodiment, the first conductivity can be For N-type doping, the base layer 12 has an electron concentration greater than that of the drift layer 11, but not limited thereto. The drift layer 11 further includes an active region 111 and a termination region 112 , and the termination region 112 surrounds the active region 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com