Roller-way-type solar cell irradiation annealing furnace

A technology for solar cells and annealing furnaces, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of no cell irradiation annealing treatment, etc., and achieve the effects of large production capacity, stable operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

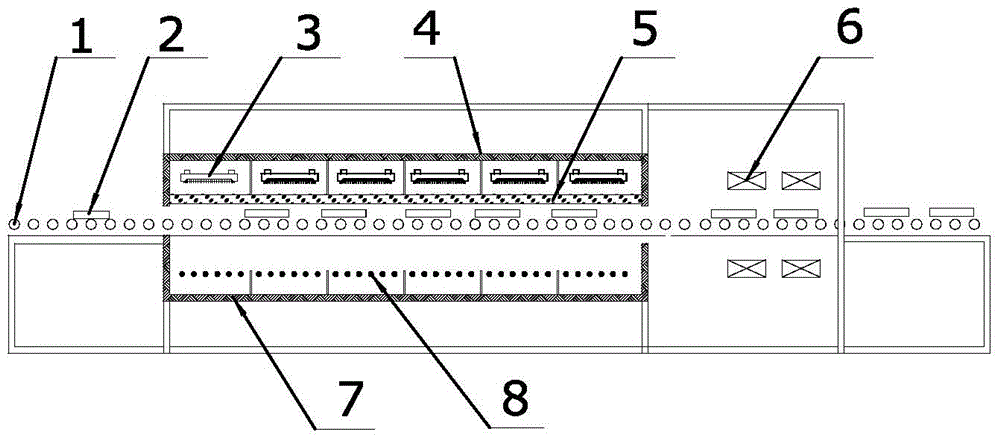

[0022] like figure 1 As shown, the roller table type solar cell irradiation annealing furnace is composed of a roller table 1, a light source 3, an upper furnace shell 4, a light-transmitting and heat-insulating material layer 5, a cooling fan 6, a lower furnace shell 7 and a heating device 8. The furnace shell 4 and the lower furnace shell 7 form a furnace cavity, and the roller table 1 is arranged in the horizontal direction and passes through the furnace cavity. The lower part is provided with a heating device 8, and a light source 3 is provided on the upper part of the irradiation annealing furnace. In the chamber where the light source 3 is installed, a blowing cooling device or an exhaust device for cooling the light source 3 is provided to cool the light source 3. The lower part of the light source 3 is provided with a light-transmitting and heat-insulating material layer 5, which separates the heating area from the light source 3, so as to prevent the heat from burning...

Embodiment 2

[0026] The battery sheet 2 travels horizontally under the transmission of the roller table 1, a light source 3 is installed at the lower part of the radiation annealing furnace, a heating device 8 is installed at the upper part of the radiation annealing furnace, and a The light-transmitting and heat-insulating material layer 5 separates the upper heating area from the light source 3 , and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| irradiance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com