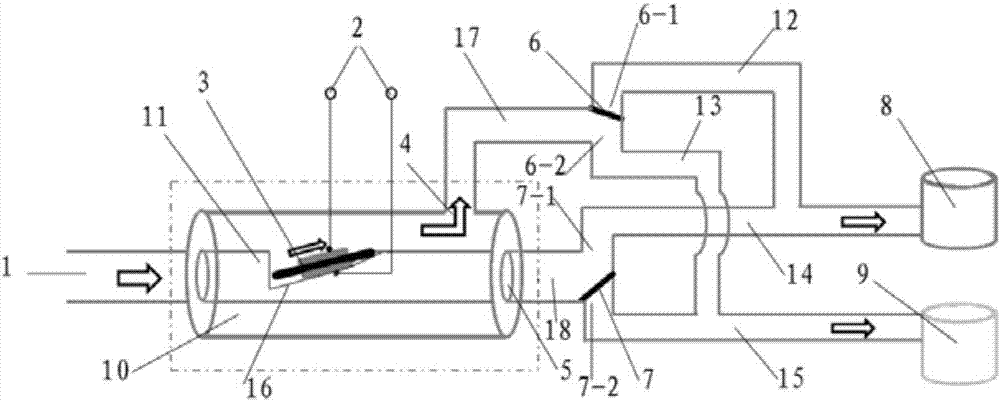

An electrolytic cell device for stable operation of hydrogen production by high-temperature electrolysis of water, preparation of the electrolytic cell, and method for using the electrolytic cell device

A stable operation, high-temperature electrolysis technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of electrolytic cell performance attenuation, achieve the effect of eliminating resistance increase, low cost, and improving long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation mode 1: The preparation method of the stable operation electrolytic cell for hydrogen production by high-temperature electrolysis of water in this embodiment is carried out according to the following steps:

[0032] 1. Electrolyte preparation: Electrolyte was prepared by casting method;

[0033] 2. Preparation of electrolyte film: prepare electrolyte film by high-temperature sintering method with the electrolyte in step 1;

[0034] 3. Preparation of ceramic powder: use sol-gel method, solid-phase reaction method, glycine combustion method or citric acid combustion method to prepare ceramic powder;

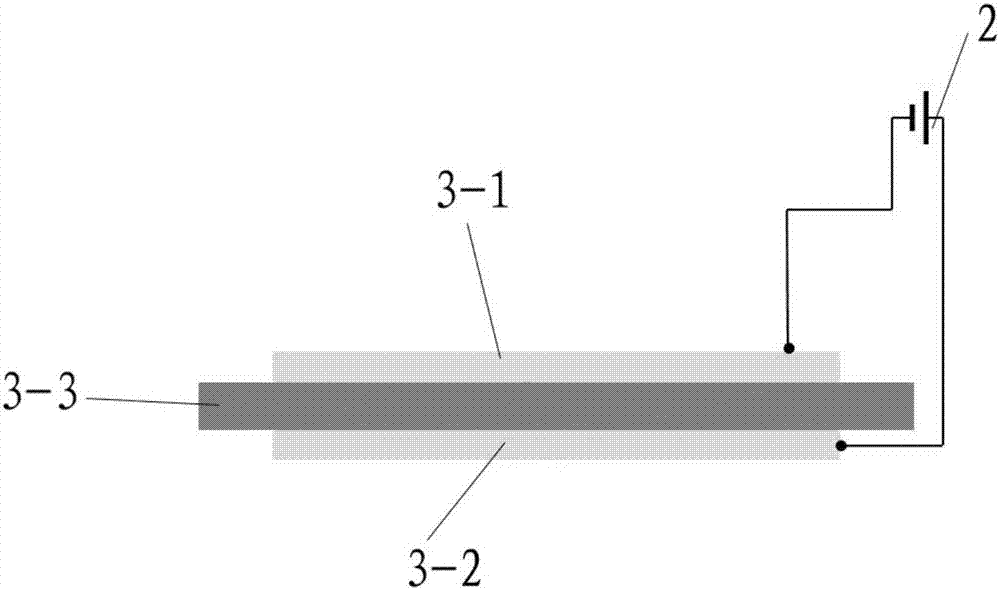

[0035] 4. Preparation of porous electrodes: Mix the ceramic powder prepared in step 3 and the pore-forming agent evenly to obtain a mixture, and use screen printing to prepare symmetrical porous electrodes on both sides of the electrolyte film prepared in step 2. The porosity of the electrodes is 20 -50%; The specific steps of the screen printing met...

specific Embodiment approach 2

[0037] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the electrolyte described in step 1 is Y 2 o 3 Stable ZrO 2 Electrolyte, Sm-doped CeO 2 Electrolyte, Gd-doped CeO 2 Electrolyte, Sc stabilized ZrO 2 Electrolyte, Sr-stabilized LaGaO 3 Electrolyte, Mg stabilized LaGaO 3 One or a mixture of electrolytes. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment is different from Embodiment 1 in that the sintering temperature of the high-temperature sintering method in Step 2 is 1200°C-1600°C. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com