Extrusion-molded two-layer tube for medical use and infusion bag product

A technology of extrusion molding and double-layer tubes, which is applied in the field of medical extrusion double-layer tubes and infusion bag products using the tubes, medical extrusion double-layer tubes, and can solve the problem of increasing the number of product manufacturing processes and waste , unable to eliminate problems such as adhesion, to achieve the effect of excellent product operability, ensure flexibility, and excellent operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described in detail.

[0028] The medical extruded double-layer tube of the present invention has a double-layer structure with an inner layer and an outer layer, the inner layer is made of flexible material, and the outer layer is made of a material with a higher melting point.

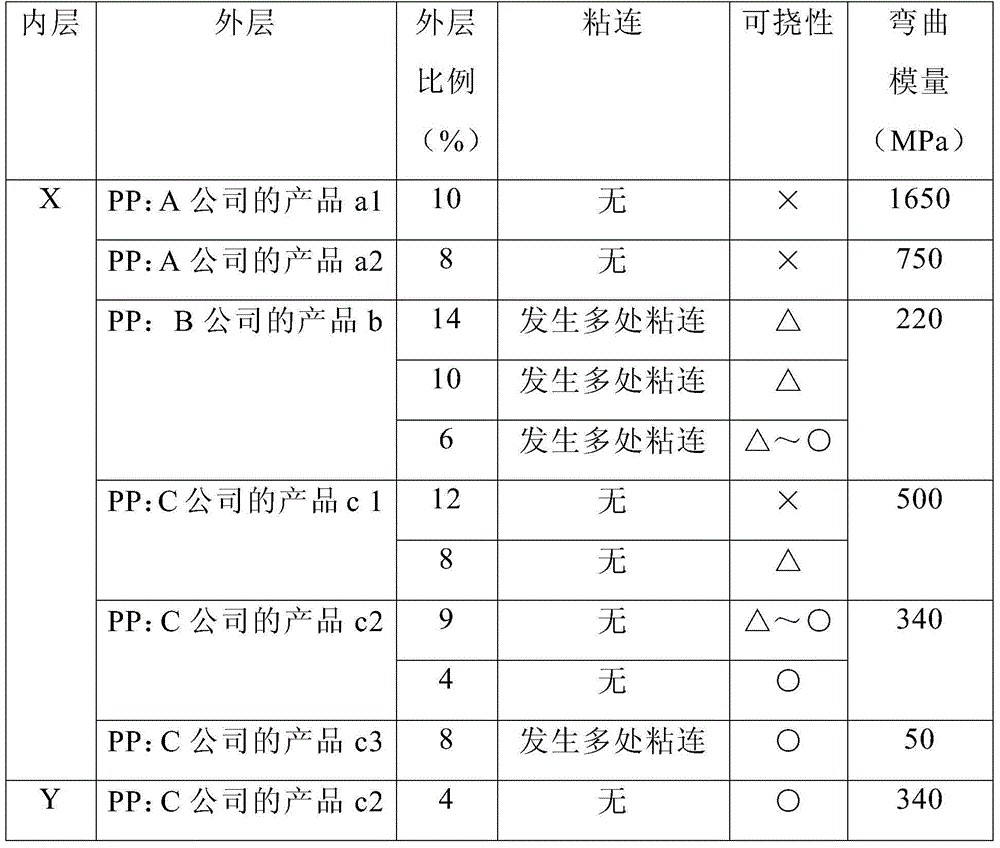

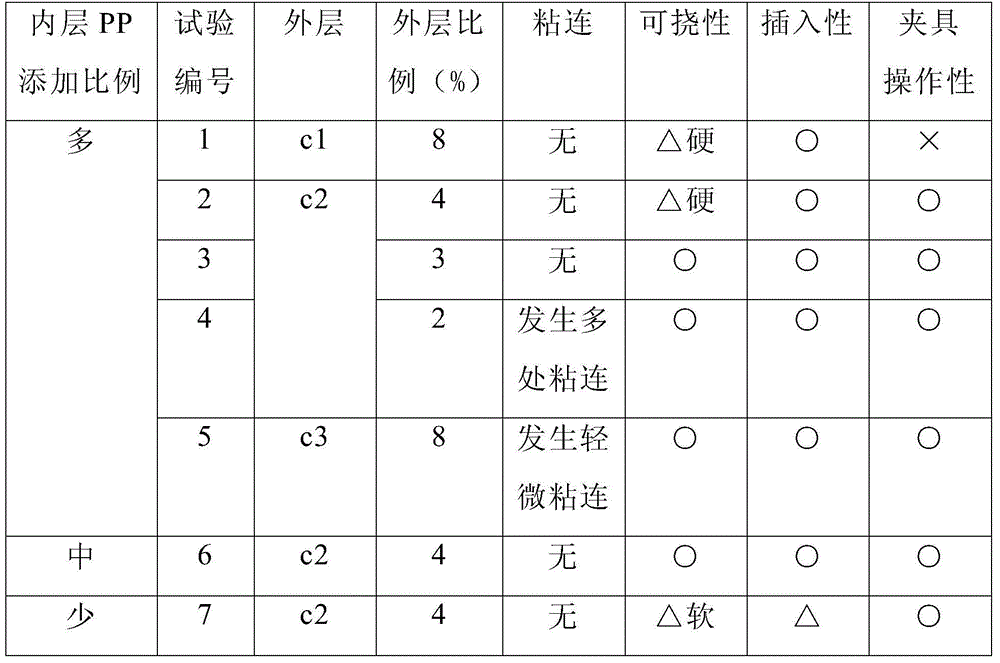

[0029] First, a preliminary test is performed. Prepare two kinds of composite materials of styrene-based elastomers with a melting point below 120°C, both of which are used in existing medical tubes, for the inner layer. Polypropylene from various companies is used for the outer layer, and the thickness of the outer layer is 4 to 14 of the overall thickness. %, for tube extrusion molding.

[0030] As an evaluation item, the presence or absence of blocking with the resin film for packaging was checked. Specifically, the tube was placed on the polypropylene side (package inner material) of a packaging resin film composed of a double-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com