Photovoltaic generation greenhouse with adjustable solar illumination and uniform illumination

A photovoltaic power generation greenhouse and uniform illumination technology, which is applied in greenhouse cultivation, renewable energy machines, agricultural machinery and equipment, etc., can solve problems affecting plant yield and quality, affecting normal plant growth and development, and affecting plant growth, etc., to achieve easy The effect of large-scale construction, improved planting capacity, and expanded irradiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

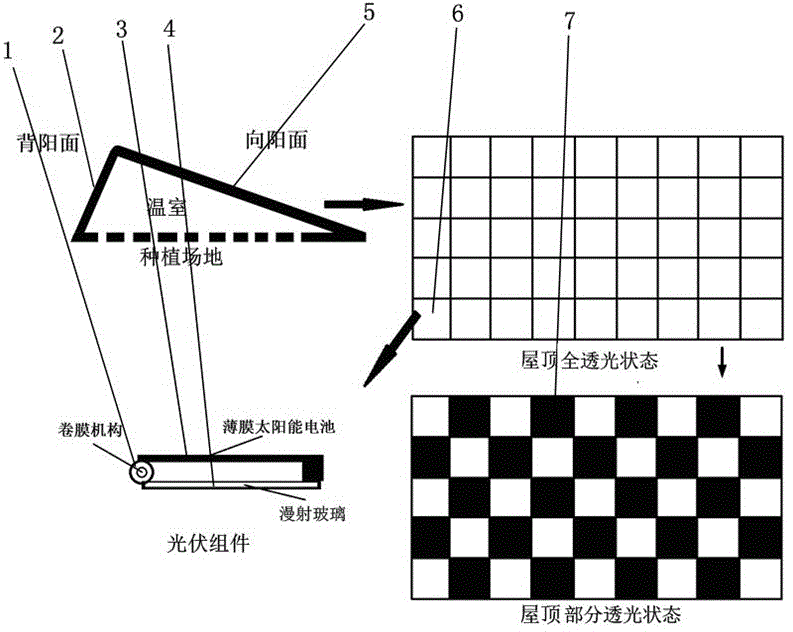

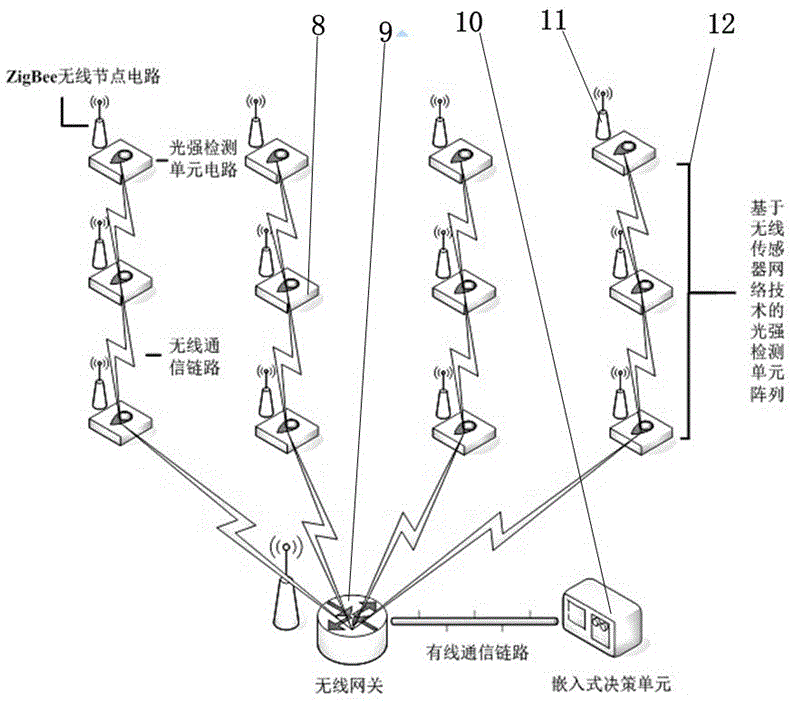

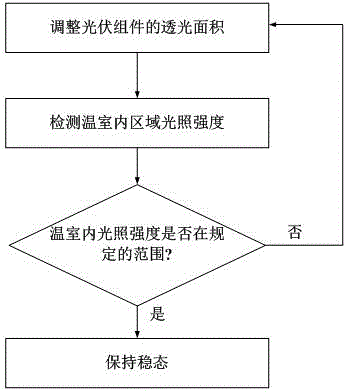

[0043] Such as figure 1 , figure 2 , image 3 As shown, when the greenhouse starts to work, the thin-film solar cells 3 of the photovoltaic modules 6 and 7 at the sunny side 5 are all rolled up, presenting as figure 1 In the fully light-transmitting state of the roof, the decision-making unit 10 acquires the indoor light intensity data detected by the light intensity detection unit array 12 at a certain time interval, and compares it with the light intensity and illuminance value required for the normal operation of the greenhouse to judge the current greenhouse indoor light intensity data. Whether the light intensity is within the specified range, if the detected light intensity data exceeds 1.2 times the light intensity required for normal operation of the greenhouse, then the decision-making unit 10 considers that the light intensity exceeds the standard at this time, and needs to reduce the light intensity in the greenhouse to the required light intensity for normal work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com